Preparation method of iturinA micro capsule

A technology of iturin and microcapsules, applied in the field of preparation of iturin A microcapsules, can solve problems such as no reports of iturinA microcapsules, and achieve prolonged bacteriostatic efficacy and good storage stability , good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A preparation method of iturin A microcapsules, comprising the following steps:

[0029] (1) Preparation of microcapsule wall material aqueous solution:

[0030] I. according to mass percentage, prepare 1.25% sodium alginate aqueous solution, for subsequent use;

[0031] II. Prepare a 1.25% aqueous solution of γ-polyglutamic acid according to the mass percentage, and set aside.

[0032] (2) Preparation of microcapsule emulsion:

[0033] Take 200ml of the 1.25% sodium alginate aqueous solution prepared by step (1), slowly add 25ml, 128μg / ml iturin A aqueous solution under 40°C, 495r / min magnetic stirring, and stir for 20min under the same conditions, then slowly add the step (2) Prepare the aqueous solution of 200ml 1.25% gamma-polyglutamic acid, keep stirring for 5h, 20Mpa high-pressure homogenization (GYB30-6D type, Shanghai Donghua high-pressure homogenizer factory) 15min, obtain iturin A microcapsule emulsification liquid.

[0034] (3) The iturin A microcapsule e...

Embodiment 2

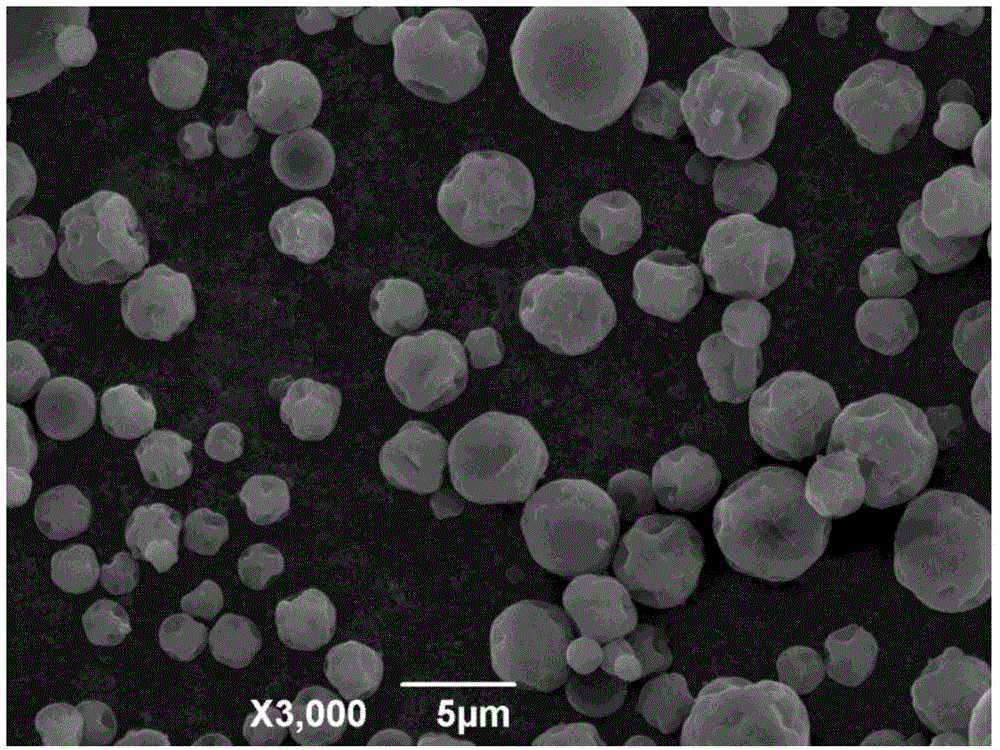

[0041] Apparent morphology of iturin A microcapsules

[0042] Sample preparation (ion sputtering instrument) → electron microscope scanner (SEM) observation

[0043] Iturin A microcapsules scanning electron microscope picture see figure 1 . It can be seen from the figure that the iturin A microcapsules have good dispersibility, are spherical, have depressions on the surface, and the particle size is relatively uniform, with a diameter of about 1.0-10.0 μm.

Embodiment 3

[0045] Determination of embedding rate of iturin A microcapsules

[0046]

[0047] I. Extraction of iturin A in microcapsules

[0048] Add 10ml of methanol (chromatographically pure) to 0.20g of microcapsules, infiltrate on a shaker at 37°C and 160r / min for 4h, treat with ultrasonic wave for 40min, centrifuge (8000r / min, 4°C, 10min) and take 1.0ml of the supernatant, and filter it with a filter head Sterilize twice, collect the filtrate, and store in a refrigerator at 4°C.

[0049] II. High performance liquid chromatography (HPLC) measures the embedding rate of iturin A microcapsules

[0050] Mobile phase: 40% acetonitrile aqueous solution, add dipotassium hydrogen phosphate 10mM, adjust pH to 7 with phosphoric acid. The detection wavelength is 200 nm, the flow rate is 0.8 ml / min, and the injection volume is 20 μl.

[0051] The embedding effect of the iturin A microcapsules prepared in Example 1 is shown in Table 1.

[0052]Preparation parameters and embedding rate of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com