Modified polyurethane waterproof surface lacquer and preparation method thereof

A polyurethane waterproof and aliphatic polyurethane technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of low mechanical properties of surface paints, achieve durability, excellent physical and mechanical properties, and meet the needs of waterproof protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

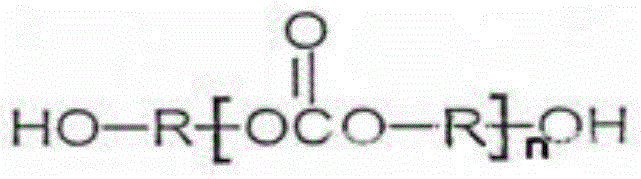

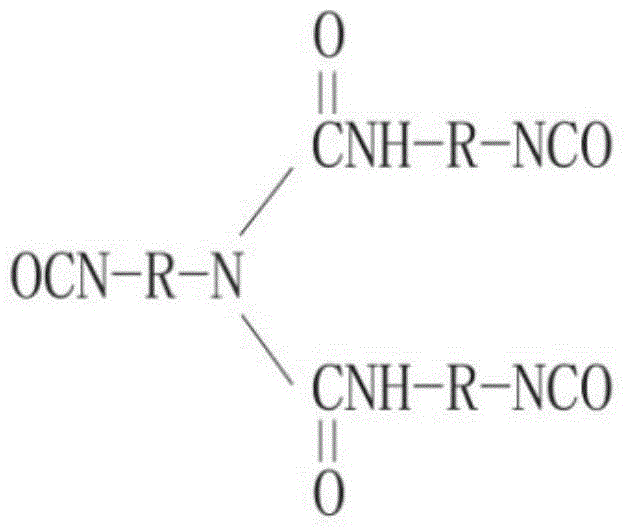

Method used

Image

Examples

Embodiment 1

[0062] The preparation of modified polyurethane waterproof surface paint of the present invention

[0063] (1) Preparation of component A

[0064] The ratio of each component in component A is as follows:

[0065] 50g polyether polyol (including 40g polypropylene oxide ether diol and 10g polypropylene oxide ether triol), 5g room temperature curing fluorocarbon resin, 30g rutile titanium dioxide, 5g filler (including 2.5g talcum powder , 1.5g barium sulfate, 0.30g medium pigment and 0.7g bentonite), 0.3g silicone (defoamer), 0.6g polyether modified polysiloxane (leveling agent), 1.0g carboxylic acid and siloxane Copolymer (dispersant) and 8g solvent (including 4.0g xylene and 4.0g butyl acetate);

[0066] The preparation method of A component is as follows:

[0067] Put the polyether polyol and fluorocarbon resin in the dispersion tank, add titanium dioxide, talcum powder, barium sulfate, mesochrome, bentonite in turn under the stirring condition of 1000-1400 rpm, and then a...

Embodiment 2

[0082] The preparation of modified polyurethane waterproof surface paint of the present invention:

[0083] (1) Preparation of component A

[0084] The ratio of each component in component A is as follows:

[0085] 42g polyether polyol (including 32g polypropylene oxide ether diol and 10g polypropylene oxide ether triol), 10g room temperature curing fluorocarbon resin, 25.5g rutile titanium dioxide, 10g filler (including 5.5g talc powder, 3.5g barium sulfate, 0.3g medium pigment and 0.7g bentonite), 0.4g silicone (defoamer), 0.8g polyether modified polysiloxane (leveling agent), 1.2g carboxylic acid and silicone Alkane copolymer (dispersant) and 10g solvent (including 5.0g xylene and 5.0g butyl acetate);

[0086] The preparation method of A component is with embodiment 1.

[0087] (2) preparation of aliphatic polyurethane curing agent

[0088] The ratio of each component in the aliphatic polyurethane curing agent is as follows:

[0089] 30g HDI biuret, 30g liquid polycarb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com