Constitutive expression genetically engineered bacterium and application thereof to produce L-alanine

A genetically engineered bacteria and constitutive expression technology, applied in the field of bioengineering, can solve the problems of high production cost and less by-products, and achieve the effects of easy operation, simple production process and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

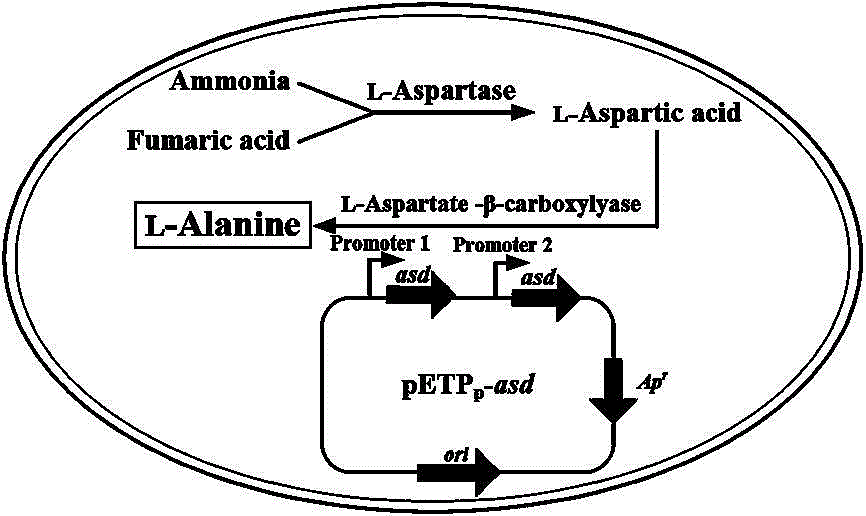

[0047] Embodiment 1. Genetically engineered bacteria E . coli / pETP p - asd build

[0048] (1) Inoculation of activated E. coli CICC 11022S in LB medium 37 o C 200 rpm shaking culture overnight.

[0049] (2) 1% inoculum transfer E. coli 11022S in fresh LB medium, 37 o Shake at C 200 rpm for 2-4 h.

[0050] (3) Transfer the culture to a 1.5 mL sterile centrifuge tube and place on ice for 30 min, 4 o Centrifuge at 4000 rpm for 5 min, and discard the supernatant.

[0051] (4) Add 200 μL of pre-cooled 0.1 mol / L CaCl to the cell pellet 2 , ice bath 5 min, 4 o Centrifuge at 4000 rpm for 5 min, and discard the supernatant.

[0052] (5) Add 50 μL of pre-cooled 0.1mol / L CaCl to the cell pellet 2 and 1 μL vector pETPp- asd , mix well, and ice bath for 20-30 min.

[0053] (6) 42 o After heat shock for 30s at C, quickly ice-bath for 2-3 min, add 400 μL fresh LB medium, 37 o C 160 rpm shake recovery culture for 1 h.

[0054] (7) Take 100 μL of the recovery culture ...

Embodiment 2

[0055] Example 2. Strains E . coli / pETP p - asd fermentation culture

[0056] Streak the genetically engineered strain onto an LB medium plate containing 100 mg / L ampicillin and 1.5 – 2.0% agar, 30±1 o C cultured for 12±2 hours to obtain a single colony.

[0057] Under sterile conditions, use a sterilized toothpick to pick a single colony on the plate, inoculate the fermentation medium, 30±1 o C culture on a shaker for 12±2 hours to obtain seed liquid.

[0058] Inoculate the seed liquid into the fermentation medium with 0.1 – 5% inoculum, 30±1 o C culture on a shaker for 12±2 hours to obtain a fermentation broth.

[0059] Wherein, the formula of the LB medium is: 5 g of yeast powder, 10 g of peptone, 10 g of sodium chloride, 115 o C for 30 minutes.

[0060] The formula of the fermentation medium is: 10 g of fumaric acid, 10 g of corn steep liquor dry powder, 0.2 g of magnesium sulfate, 1.0 g of potassium dihydrogen phosphate, 1.5 g of sodium chloride, and ammonia w...

Embodiment 3

[0061] Example 3. E . coli / pETP p - asd High-density transformation of whole cells to produce L-alanine

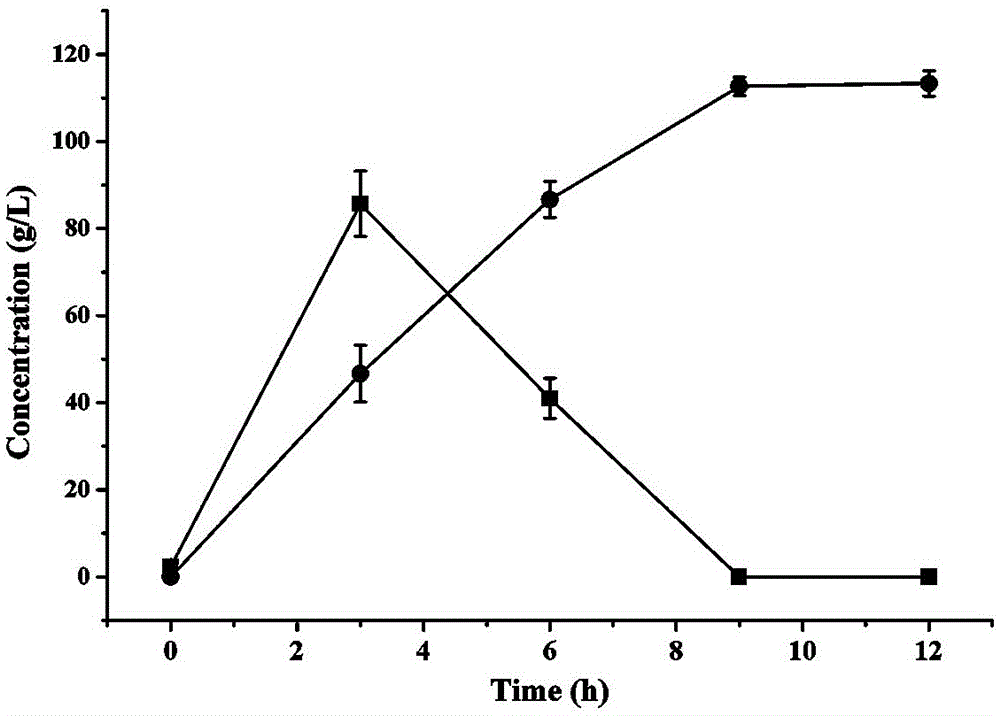

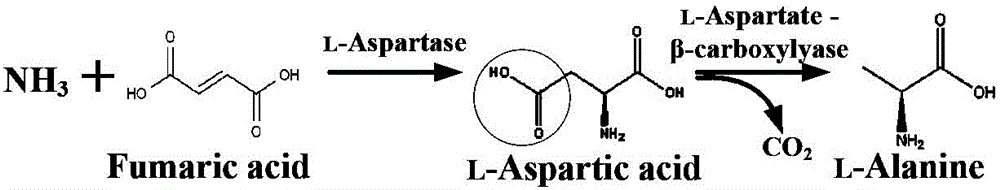

[0062] Put fumaric acid into the conversion tank, add a certain amount of water, then add ammonia water while stirring, and measure the pH change of the solution with a pH meter. After the fumaric acid is completely dissolved, adjust the pH to 7.0-8.5 with ammonia water to control Fumaric acid final concentration 0.5 – 1.2 mol / L. cultured by fermentation E . coli / pETP p - asd The bacterial liquid was collected by centrifugation, suspended in normal saline, and added to the transformation tank until the bacterial cell density OD 600 = 10 – 20. Adjust temperature 40 – 50 o C, stirring at 50 – 200 rpm for transformation. Regular sampling, high performance liquid chromatography quantitatively detects the production of L-alanine (attached image 3 ). After 9 hours, the production of L-alanine can reach 112.7 g / L, the production rate is 12.5 g / (L·h), and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com