Method for preparing super-oleophobic surface by taking kaolin as raw material

A superoleophobic and kaolin technology, applied in metal material coating process, coating, solid-state chemical plating and other directions, can solve the problems of long experimental period and complicated experimental equipment, and achieve short experimental period, simple preparation method, and low cost. Effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

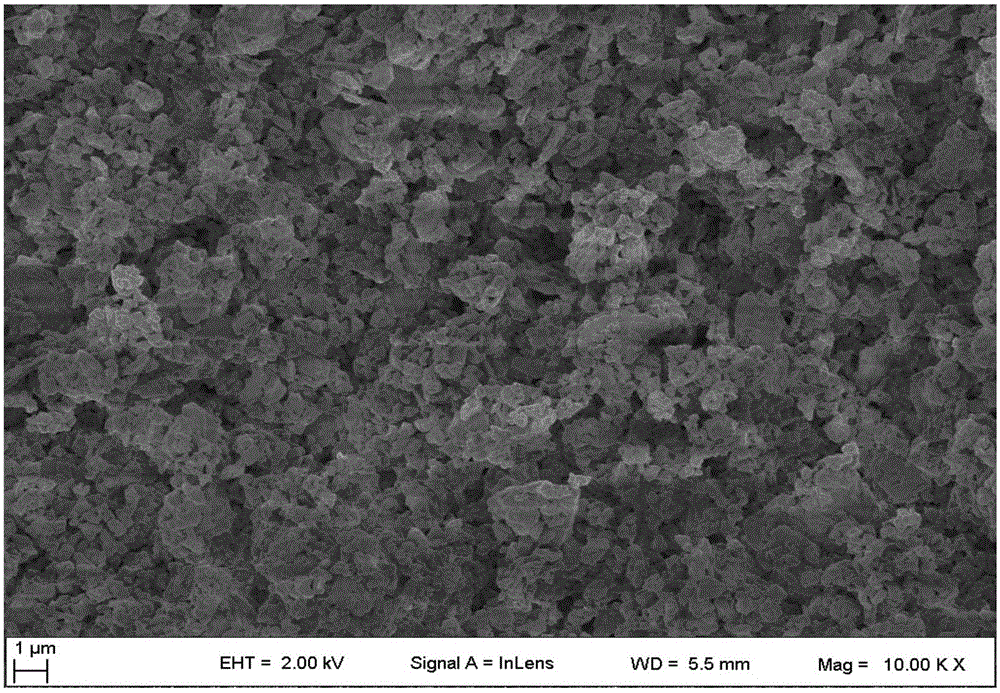

[0029] The preparation method of the present embodiment comprises the following steps:

[0030] Step 1. Add 0.3g of sodium hydroxide, 3g of perfluorooctanoic acid and 72mL of distilled water into a round bottom flask, stir at room temperature until the sodium hydroxide and perfluorooctanoic acid are completely dissolved to obtain a mixed solution, and then add 30g of kaolin powder to the mixed solution (Chemical pure reagent), ultrasonically dispersed at room temperature for 20 minutes;

[0031] Step 2. Heat the mixed solution dispersed by ultrasonic in Step 1 in an oil bath to 50° C. under stirring condition, and then keep it warm for 1 hour to obtain a suspension;

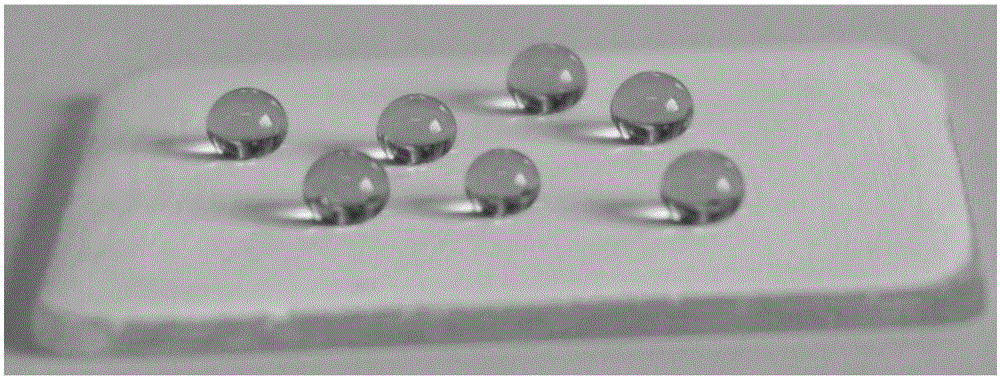

[0032] Step 3. Apply the suspension described in step 2 evenly on the substrate (glass slide), then dry the substrate coated with the suspension for 30 minutes at room temperature, and then place the dried substrate in a dry place. In the box, dry at 120°C for 2 hours, and finally wipe the dried surface of the s...

Embodiment 2

[0036] The preparation method of the present embodiment comprises the following steps:

[0037] Step 1. Add 0.15g of sodium hydroxide, 0.75g of perfluorooctanoic acid and 30mL of absolute ethanol into a round bottom flask, stir at room temperature until the sodium hydroxide and perfluorooctanoic acid are completely dissolved to obtain a mixed solution, and then add 15g of kaolin powder (chemically pure reagent), ultrasonically dispersed for 30min at room temperature;

[0038] Step 2: Heat the ultrasonically dispersed mixed solution in Step 1 in an oil bath to 60°C under stirring conditions, and then keep it warm for 1 hour to obtain a suspension;

[0039] Step 3. Apply the suspension described in step 2 evenly on the substrate (glass slide), then dry the substrate coated with the suspension for 40 minutes at room temperature, and then place the dried substrate in a dry place. In the box, dry at 100°C for 2 hours, and finally wipe the dried surface of the substrate (it can be ...

Embodiment 3

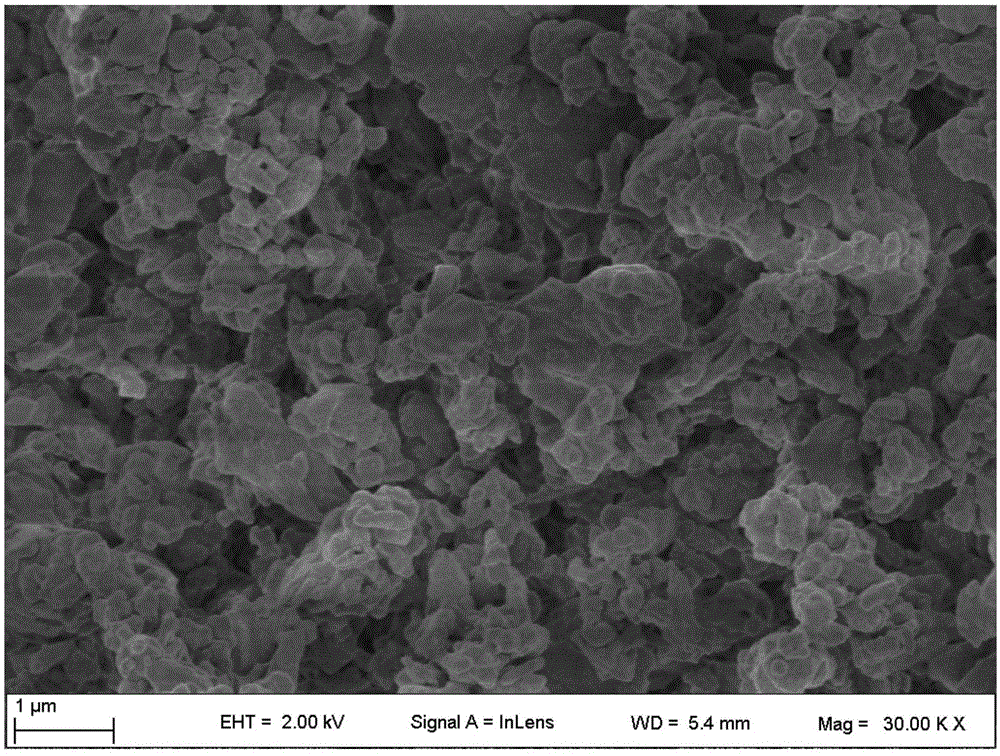

[0042] The preparation method of the present embodiment comprises the following steps:

[0043] Step 1. Add 0.15g of sodium hydroxide, 0.75g of perfluorooctanoic acid and 15mL of absolute ethanol into a round bottom flask, stir at room temperature until the sodium hydroxide and perfluorooctanoic acid are completely dissolved to obtain a mixed solution, and then add 5g kaolin powder (chemically pure reagent), ultrasonically dispersed at room temperature for 10min;

[0044] Step 2. Under stirring conditions, heat the mixed solution dispersed by ultrasonic in Step 1 in an oil bath to 55° C. and keep it warm for 1.5 hours to obtain a suspension;

[0045] Step 3, apply the suspension described in step 2 evenly on the substrate (aluminum alloy metal sheet), then dry the substrate coated with the suspension for 20 minutes at room temperature, then place the dried substrate on In a drying oven, dry at 110° C. for 1.5 h, and finally wipe the dried surface of the substrate (it can be w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com