Nano-cellulose/cellulose triacetate composite nano-fiber membrane capable of adsorbing and desorbing proteins

A technology of composite nanofibers and triacetate cellulose, which is applied in the field of protein separation and purification, can solve the problems of increasing processing costs, restricting expansion, and increasing technological processes, and achieves the advantages of improving adsorption, optimizing size and distribution, and increasing protein adsorption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

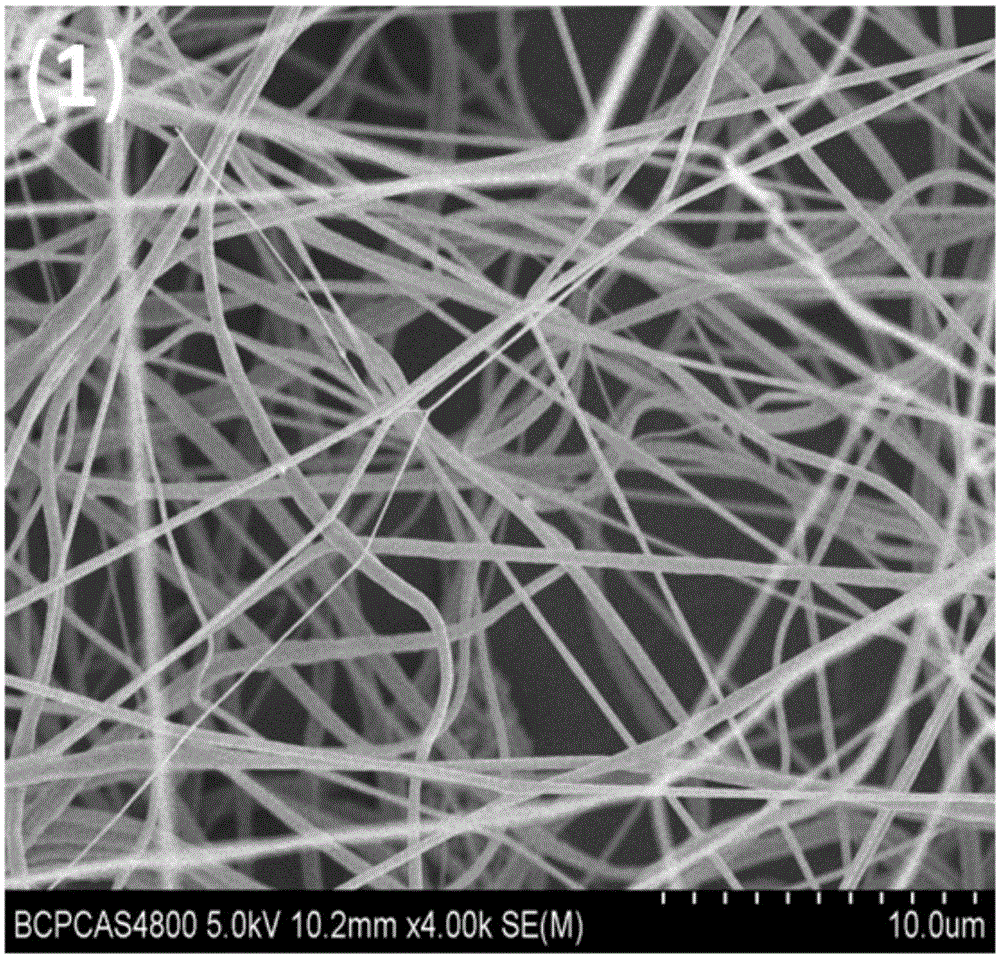

[0040] Weigh 1.2g of cellulose triacetate, 9mL of dimethyl sulfoxide and 3mL of chloroform solvent (solvent volume ratio 3:1) into a 20mL Erlenmeyer flask, and stir magnetically at room temperature for 8-12h to form a transparent homogeneous spinning Silk liquid: After stirring evenly, let the spinning liquid stand for degassing for 8 hours, then pour it into a 20mL syringe equipped with a #7 needle, fix it on a double-channel micro-injection pump, set the injection speed to 1-4mL / h, and adjust A high-voltage generator keeps the voltage at 20-25kV and the humidity at 45%-55%. The needle droplet quickly forms a Taylor cone, and a triacetate cellulose nanofiber film is formed on the conductive receiving plate with aluminum foil. Then, soak the membrane in deionized water for 24 hours to remove residual solvents and impurities, and dry it in an oven at 60°C to obtain pure cellulose triacetate nanofiber membrane 1, the scanning electron microscope image of which is shown in figure...

Embodiment 2

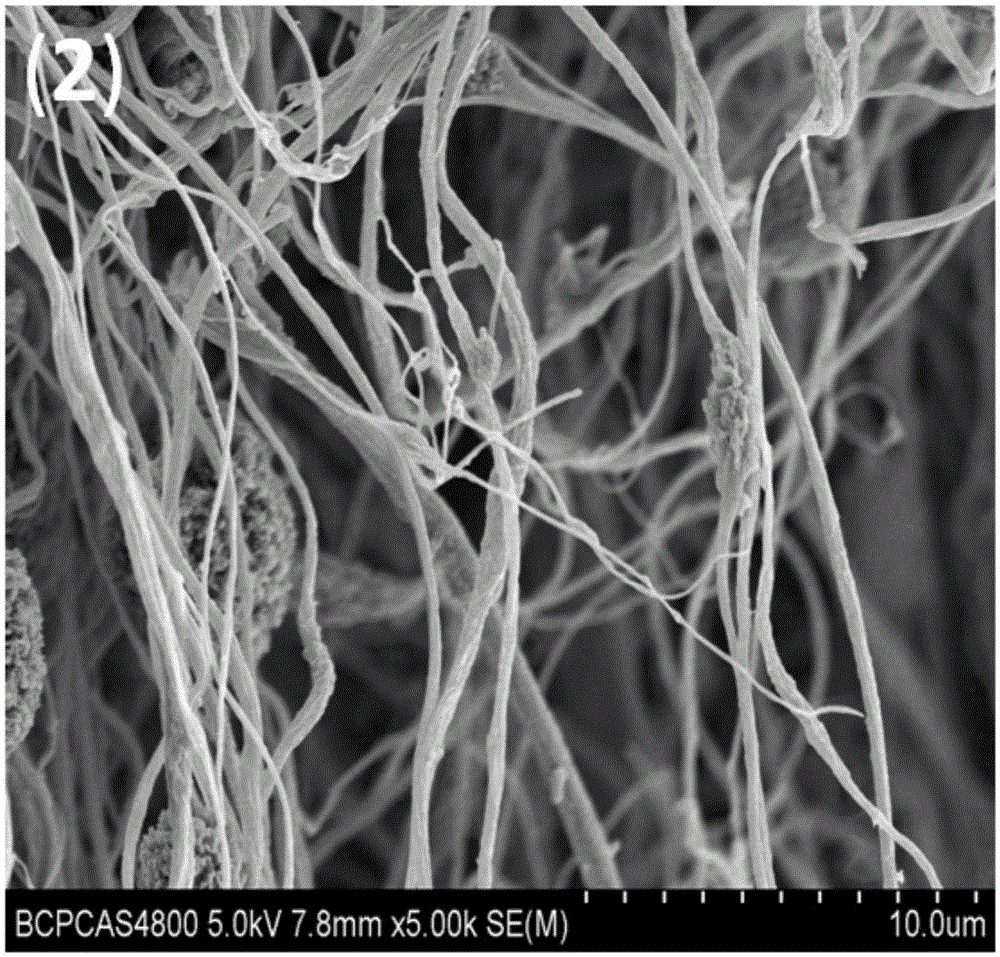

[0044] (1) Add 10g of wood pulp to the oxidation system of TEMPO (0.05g), NaBr (0.5g) and NaClO (12g), adjust the pH to around 10 with NaOH and react for 6h, then obtain nanocellulose by washing, filtering, and ultrasonic centrifugation Water suspension (0.2% solid content);

[0045] (2) Dissolve 0.74 g of cellulose triacetate in 8.03 g of dimethyl sulfoxide, stir magnetically at 80° C. for 12 hours, then stop stirring, keep warm and stand for defoaming (mass fraction of substrate is 5%);

[0046] (3) Weigh 1.85g of the nanocellulose aqueous suspension obtained in step (1), then slowly drop 1.85g of dimethyl sulfoxide solvent into the suspension, and then vacuumize and rotary evaporate at 80°C for 4h to obtain nanocellulose Dimethyl sulfoxide suspension;

[0047] (4) Slowly add 1.85 g of the nanocellulose dimethyl sulfoxide suspension obtained in step (3) dropwise into the solution in step (2), stir magnetically at 80°C for 4 hours, then drop the temperature to 40°C and add 4...

Embodiment 3

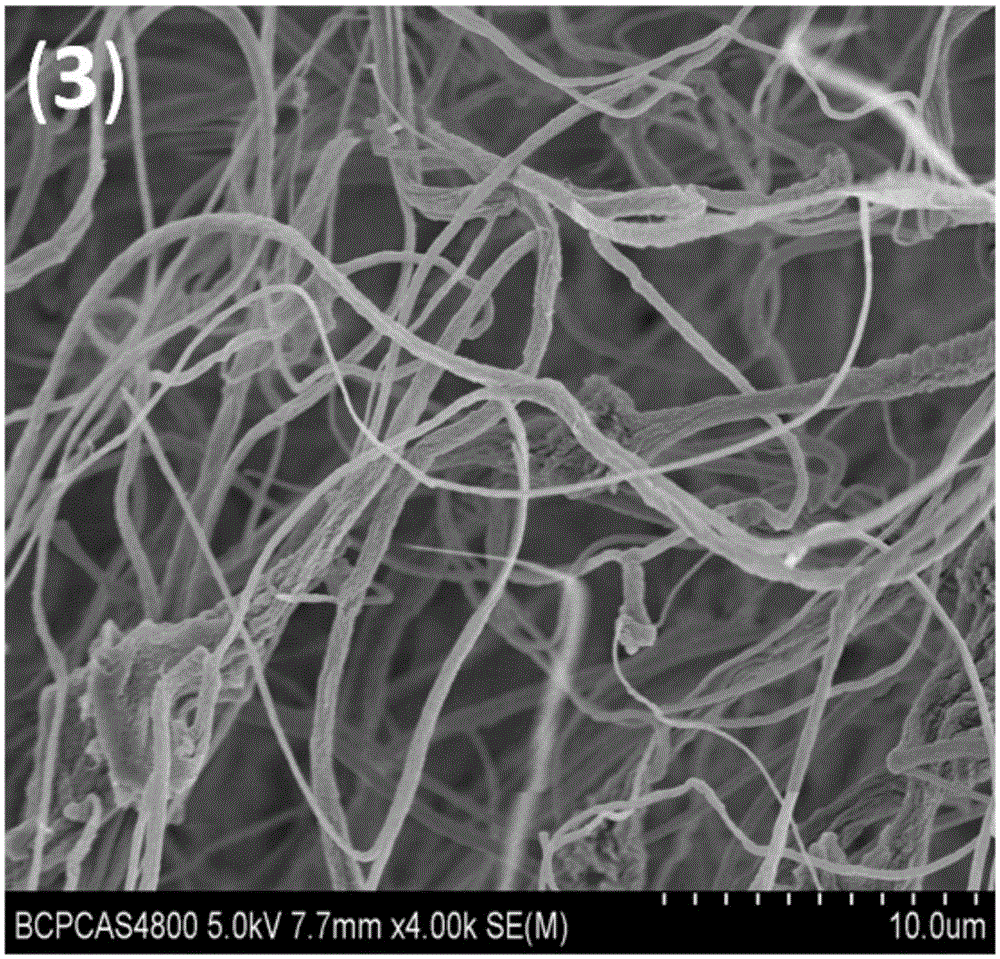

[0053] (1) Add 10g of wood pulp to the oxidation system of TEMPO (0.05g), NaBr (0.5g) and NaClO (12g), adjust the pH to around 10 with NaOH and react for 6h, then obtain nanocellulose by washing, filtering, and ultrasonic centrifugation Water suspension (0.2% solid content);

[0054] (2) Dissolve 0.74 g of cellulose triacetate in 6.17 g of dimethyl sulfoxide, stir magnetically at 80°C for 12 hours, then stop stirring, keep warm and stand for defoaming;

[0055] (3) Weigh 3.71g of the nanocellulose aqueous suspension obtained in step (1), slowly add 3.71g of dimethyl sulfoxide solvent into the suspension, and then vacuumize and rotary evaporate at 80°C for 4h to obtain nanocellulose Dimethyl sulfoxide suspension;

[0056] (4) Slowly add 3.71 g of the nanocellulose dimethyl sulfoxide suspension obtained in step (3) dropwise into the solution in step (2), stir magnetically at 80°C for 4 hours, then drop the temperature to 40°C and add 4.22g of chloroform , to obtain nanocellulo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com