Method of preparing titania nanotube/carbon/manganese oxide composite material by using gaseous penetration method

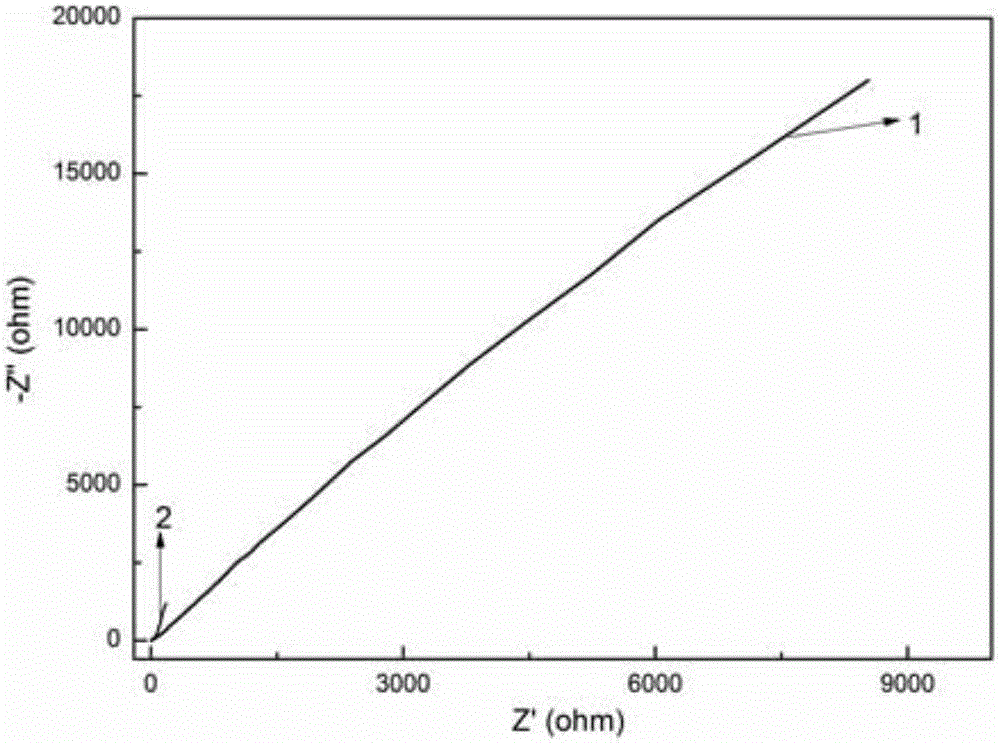

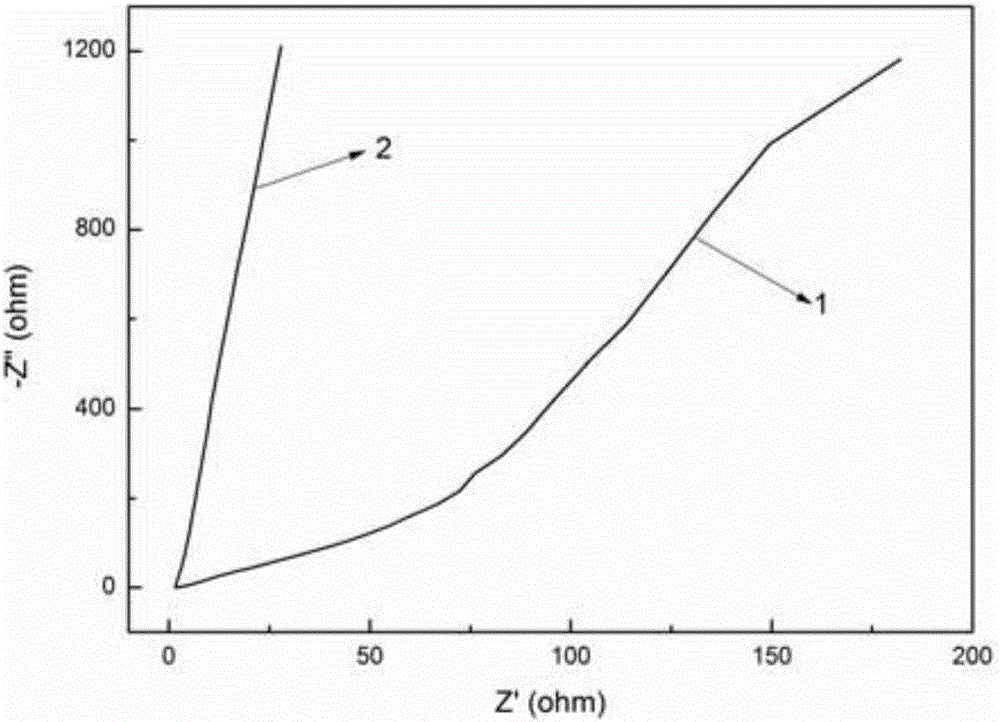

A technology of titanium oxide nanotubes and composite materials, which is applied in the field of composite material preparation, can solve problems such as poor capacitance performance and large resistance, and achieve the effects of improving capacitance performance, reducing resistance and increasing capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

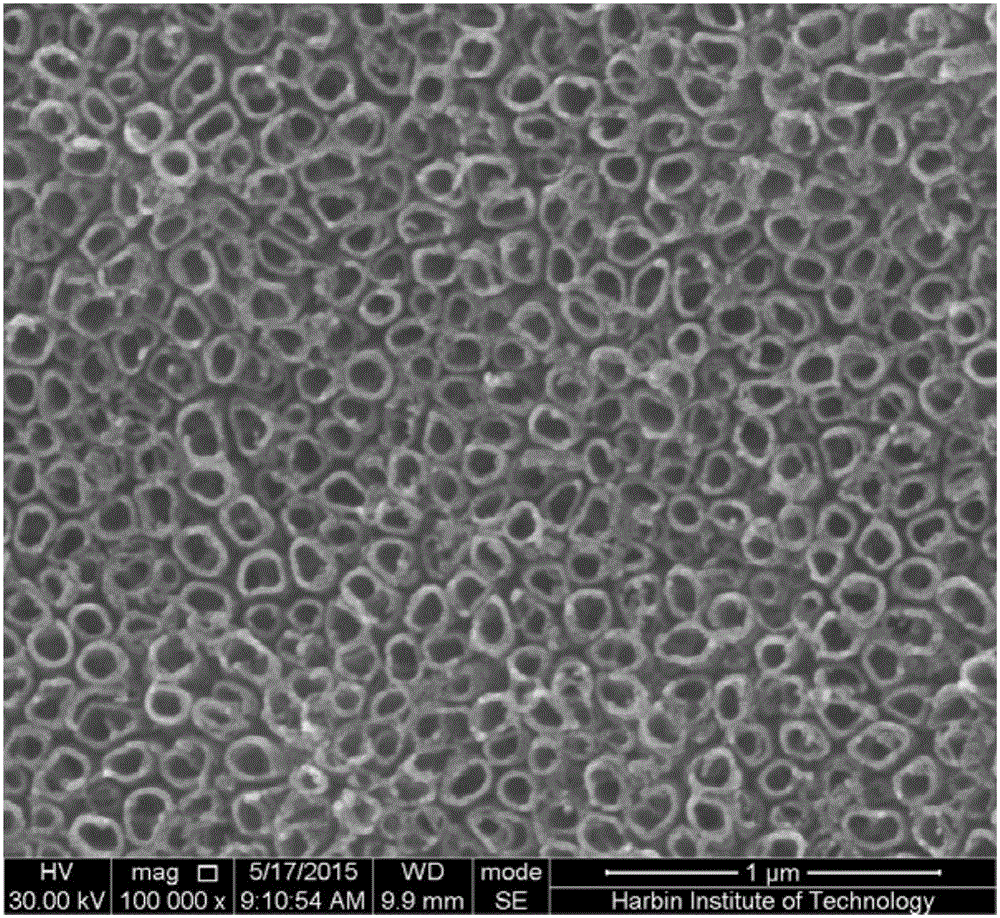

[0025] Specific embodiment one: this embodiment is a kind of method that utilizes vapor phase diffusion infiltration method to prepare titanium oxide nanotube / carbon / manganese oxide composite material is finished according to the following steps:

[0026] 1. Use 120#SiC sandpaper, 1000#SiC sandpaper and 2000#SiC sandpaper to polish the titanium sheet in sequence to obtain a titanium sheet with a bright surface;

[0027] 2. Use absolute ethanol and acetone to clean the titanium sheet with a bright surface for 3 to 5 times respectively to obtain the treated titanium sheet;

[0028] 3. Add the electrolyte solution into the inorganic glass electrolytic cell, connect the processed titanium sheet to the positive pole of the power supply as the anode, and connect the copper sheet to the negative pole of the power supply as the cathode; use a DC power supply for power supply at a voltage of 10V React at ~30V for 60min~90min, take out the reacted titanium sheet;

[0029] 4. Drying the...

specific Embodiment approach 2

[0041] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in step 3, a DC power supply is used for power supply, and the reaction is performed at a voltage of 10V-20V for 60min-75min, and the reacted titanium sheet is taken out.

[0042] Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0043] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in step 3, a DC power supply is used for power supply, and the reaction is performed at a voltage of 20V-30V for 75min-90min, and the reacted titanium sheet is taken out. Other steps are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com