Reactive dye non-aqueous medium dyeing and soaping method

A technology of reactive dyes and non-aqueous medium, applied in the field of dyeing and soaping of reactive dyes, can solve the problems of difficult handling, large amount of surfactant co-surfactant, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The non-aqueous medium dyeing and soaping method of the reactive dye that the present embodiment provides, it comprises the following steps:

[0056] Soak 10g of pure cotton knitted fabric in 10g / L aqueous solution of sodium carbonate to 100% liquid retention rate, double dipping and rolling, and dry at 60°C for 10 minutes;

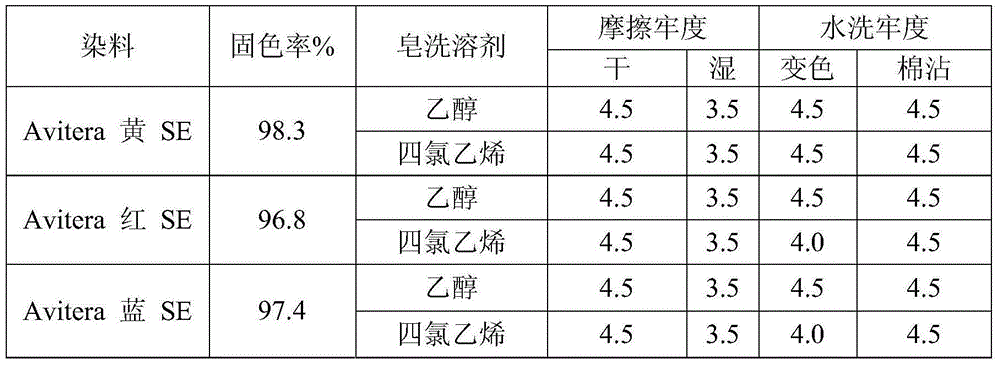

[0057] Put the alkali-pretreated knitted fabric in the dyeing cup, add 0.3g (3% o.m.f) of reactive dyes listed in Table 2, 50mL of dimethyl sulfoxide, dye at 35°C, and dye at 1°C / min Slowly increase the temperature at a rate of 100%, slowly add 300mL of tetrachlorethylene during the heating process, and raise the temperature to 130°C for 2 hours;

[0058] Take out the dyed cloth sample, place it in 50ml didodecyl dimethyl ammonium bromide tetrachlorethylene / ethanol solution (concentration is 5g / L, tetrachlorethylene: ethanol is 1:5), its bath ratio 1:5. Insulate at 60°C for 20 minutes, take it out, and dry it. The knitted fabric dyed with the ga...

Embodiment 2

[0062] The non-aqueous medium dyeing and soaping method of the reactive dye that the present embodiment provides, it comprises the following steps:

[0063] Soak 10g of cotton / nylon (70% cotton + 30% nylon) blended knitting fabric in 10g / L sodium bicarbonate solution at room temperature for 10 minutes, dipping and rolling to control the liquid retention rate at 100%, and then dry it. The drying temperature is 60°C, and the drying time is 10 minutes.

[0064] Put the alkali-pretreated knitted fabric in the dyeing cup, add 0.3g (3% o.m.f) Avitera blue SE dye, 50mL of N,N-dimethylformamide, and dye at 35°C at 1°C / min Slowly increase the temperature at a rate of 100%, slowly add 300mL of n-hexane during the heating process, and raise the temperature to 130°C for 2 hours;

[0065] Take out the dyed cloth sample, place it in 30ml dioctadecyldimethylammonium chloride acetone solution (concentration: 2g / L), keep it warm at 60°C for 20min, take it out, dry it, and finish the dyeing. ...

Embodiment 3

[0069] The non-aqueous medium dyeing and soaping method of the reactive dye that the present embodiment provides, it comprises the following steps:

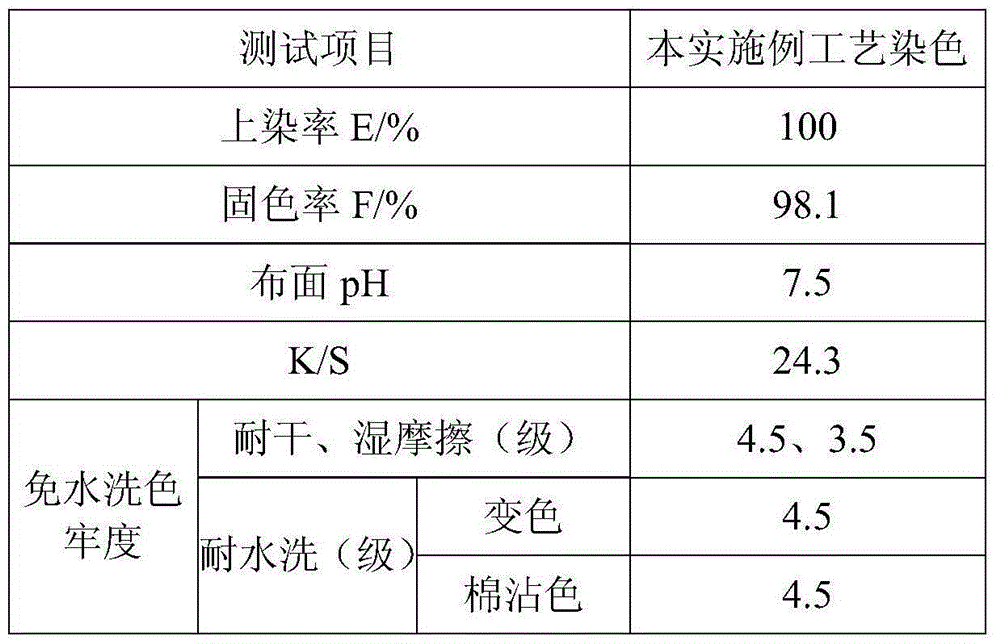

[0070] Immerse 10g of pure cotton yarn (36s / 2) in an aqueous solution of sodium carbonate with a concentration of 10g / L until the liquid-carrying rate is 100%, dipping and rolling twice, and drying at 60°C for 10 minutes;

[0071] Put the alkali-pretreated yarn in a dyeing cup, add 0.3g (3% o.m.f) Avitera red SE dye, 50mL of N,N-dimethylacetamide, and dye at 35°C at 1°C / min Slowly increase the temperature at a rate of 100%. During the heating process, slowly add 300mL of decamethylcyclopentasiloxane, and raise the temperature to 130°C for 2 hours;

[0072] Take out the dyed cloth sample, it is placed in the butyl acetate solution (40ml) of the dioctadecyl dimethyl ammonium chloride (being dioctadecyl dimethyl ammonium chloride) of 3g / L, at 60 Keep warm at ℃ for 20 minutes, take it out, and dry it to complete the dyeing. After d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com