Metal ion imprinting polymer, preparation method and applications thereof

A metal ion imprinting, metal ion technology, applied in chemical instruments and methods, other chemical processes, separation by moving adsorbents, etc., can solve the problems of easy introduction of errors, easy interface emulsification, time-consuming analysis process, etc. Mild, short development cycle, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of the metal ion imprinted polymer of the present invention comprises the following steps: mixing the functional monomer organosilane coupling agent, crosslinking agent, surfactant, and metal ion template in an appropriate amount of solvent, and then under alkaline conditions ( The pH value is about 13) to carry out polycondensation reaction to obtain a polymer containing metal ions; extract the above polymer in ethanol until the surfactant is completely extracted; clean the extracted polymer until no heavy metal ions are detected; The polymer from which the imprinted ions are removed is washed with an organic solvent to neutrality and dried under vacuum to obtain the metal ion imprinted polymer.

[0028] The metal ion-imprinted polymer of the present invention can be used to separate and enrich metal ions in environmental samples or food samples. The specific method is: the metal ion-imprinted polymer of the present invention is packed into a colu...

Embodiment 1

[0032] Example 1 Preparation of Cadmium Ion Imprinted Polymer

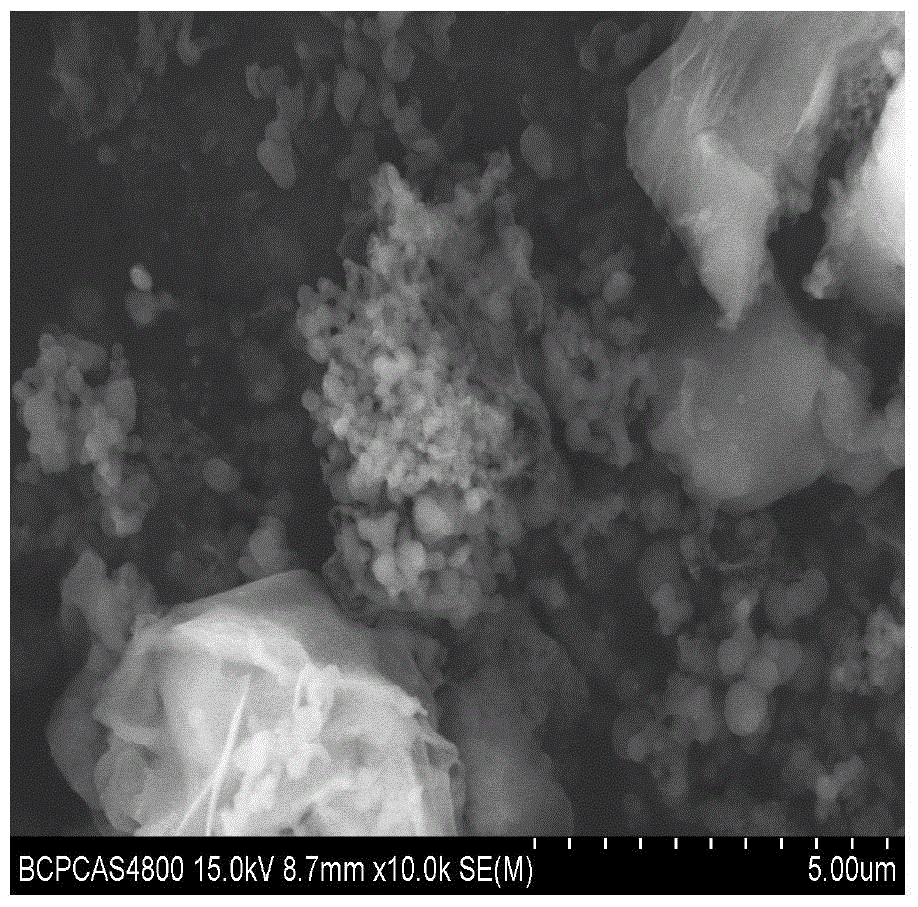

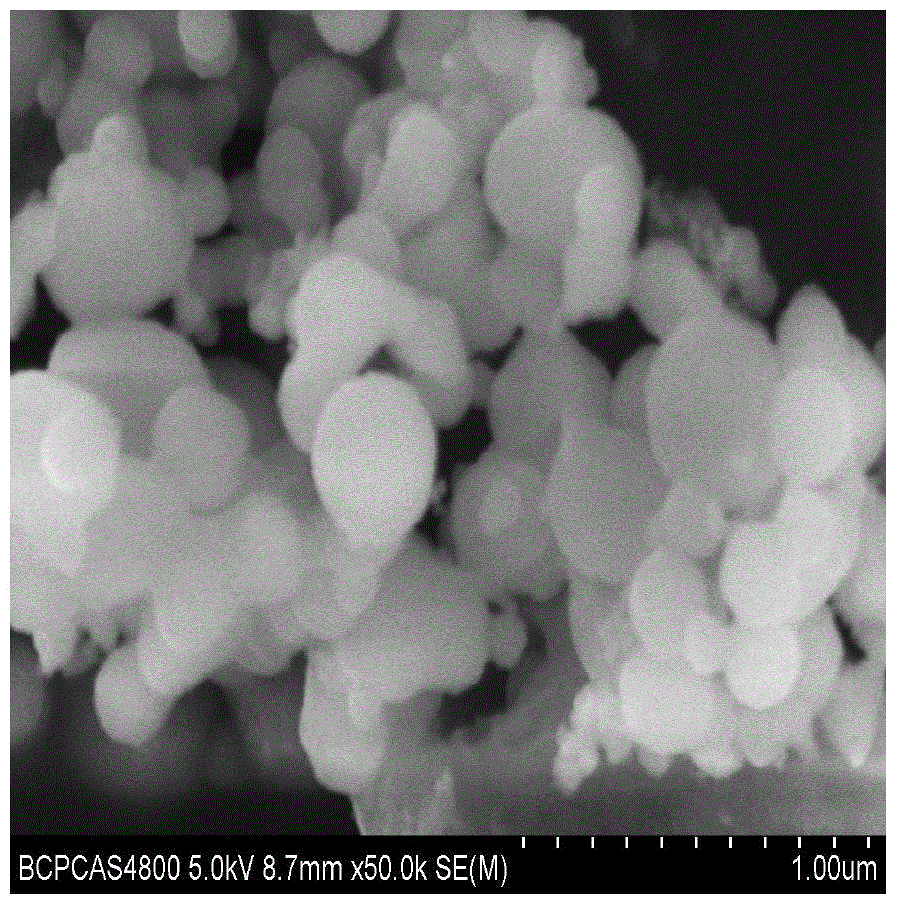

[0033] In a 250mL flask, add 0.73gCTMAB, 18.7g ultrapure water, stir to dissolve, then add 2.23mLTEOS, continue stirring for 30 minutes; take another flask, add 0.556gAAPTS, 0.274gCdCl 2 2.5H 2 O, 2ml of methanol, after stirring for 1 hour, add this solution to the previous flask and mix, add 1molL -1 NaOH 5ml, reacted for 2 days under stirring, then reacted for 1 day at 70°C, filtered with suction, dried the product in vacuum at 70°C for 12 hours, then extracted it with absolute ethanol for 24 hours, and then dried it in vacuum at 70°C for 12 hours. Afterwards, transfer the material to a 50ml centrifuge tube, add an appropriate amount of 4mol / L hydrochloric acid solution, shake and centrifuge repeatedly until no Cd ions are detected in the supernatant, and dry the obtained material in vacuum at 70°C for 12 hours to obtain cadmium ions Imprinted material, its scanning electron microscope picture is shown in fig...

Embodiment 2

[0034] Example 2 Preparation of lead ion imprinted polymer

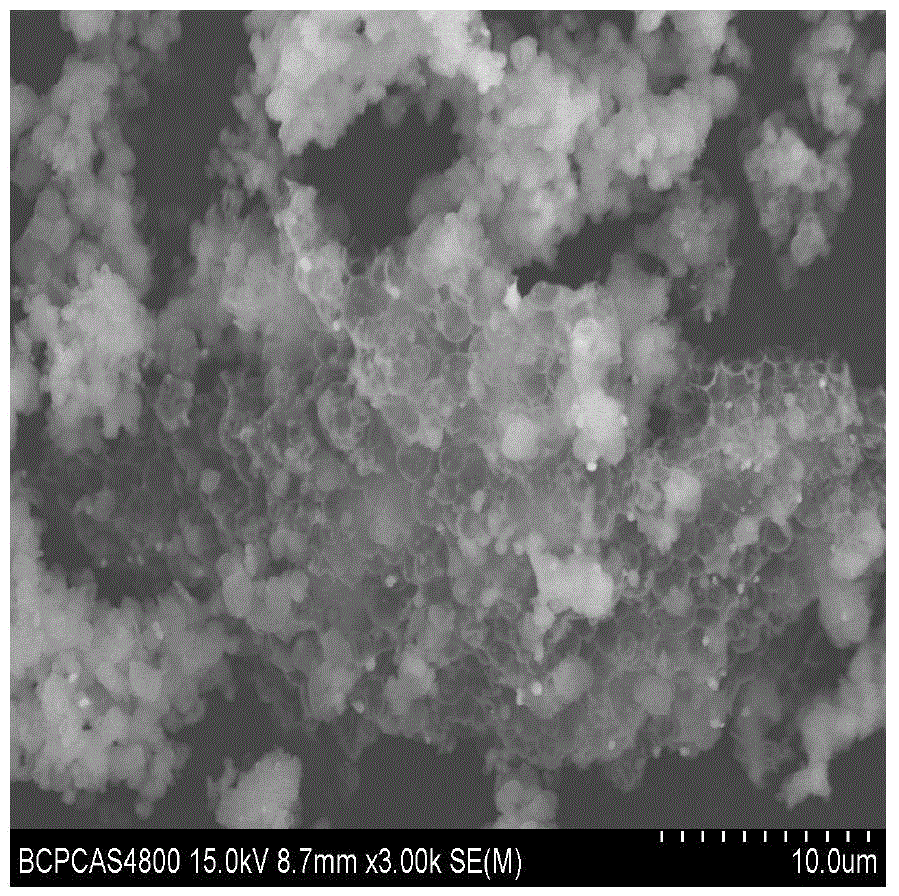

[0035] In a 250mL flask, add 1.46gMSDS, 18.7g ultrapure water, stir to dissolve, then add 2.46mLTMOS, continue stirring for 30 minutes; take another flask, add 0.556gMPS, 0.379gPb(Ac) 2 ·3H 2 O, 2ml of methanol, after stirring for 1 hour, add this solution to the previous flask and mix, add 1molL -1 NaOH 5ml, reacted for 2 days under stirring, then reacted for 1 day at 80°C, filtered with suction, dried the product in vacuum at 70°C for 12 hours, then extracted it with absolute ethanol for 24 hours, and then dried it in vacuum at 70°C for 12 hours. Afterwards, transfer the material to a 50ml centrifuge tube, add an appropriate amount of 4mol / L nitric acid solution, shake and centrifuge repeatedly, until no Pb ions are detected in the supernatant, and vacuum dry the obtained material at 80°C for 12 hours to obtain lead ions Imprinted material, its scanning electron microscope picture is shown in image 3 , Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com