QK-polypeptide-encapsulating polylactide copolymer electrospinning fibrous membrane and preparing method

A technology of polylactide and fiber membranes, applied in medical science, prostheses, etc., can solve the problems of not being able to effectively control the loading and release of QK polypeptides, and achieve good biocompatibility and degradability, and the preparation process The effect of simple operation and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The preparation method of the polylactide copolymer fiber membrane that packs QK polypeptide, the steps are as follows:

[0018] (1) Use phosphate buffered saline (PBS) to prepare an aqueous phase solution (W) at room temperature, which contains QK polypeptide (a VEGF mimic peptide, synthesized by Jill Biochemical (Shanghai) Co., Ltd.) 100-500 μg / mL, thiolated chitosan Sugar 0~6mg / mL, polyethylene glycol diacrylate 0~376μg / mL, bovine serum albumin 1~4mg / mL;

[0019] (2) Polyethylene glycol-b-poly(lactide-co-ε-caprolactone) or poly(glycolide-co-lactide) dissolved in chloroform / N,N-dimethylformamide In the mixed solvent (volume ratio 8:2), prepare a solution with a concentration of 140-180mg / mL as the oil phase solution (O);

[0020] (3) The water phase solution prepared in step (1) and the oil phase solution prepared in step (2) have a volume ratio of 1:15 to 1:25, and the water phase is added to the oil phase, and the volume of the oil phase Add 8-10 mg / mL of F127 as ...

Embodiment 1

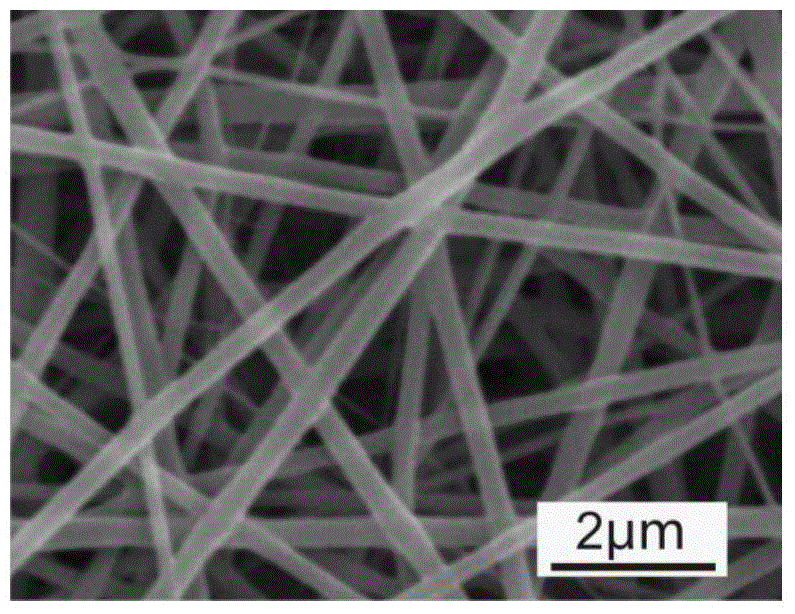

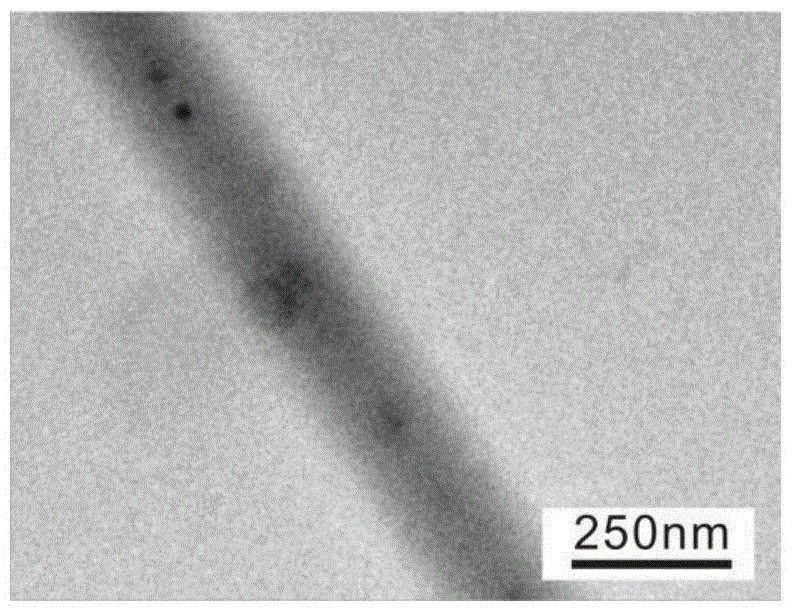

[0023] Weigh 6 mg of thiolated chitosan with a weight-average molecular weight of 50,000, 376 μg of polyethylene glycol diacrylate, 500 μg of QK polypeptide (an analog peptide of VEGF, synthesized by Jill Biochemical (Shanghai) Co., Ltd., the same below) and dissolve it in 1 mL of phosphate The buffer was used as the aqueous phase, and 4 mg of bovine serum albumin was added for protection. Weigh 900mg of PELCL and dissolve it in a mixed solvent of 4mL of chloroform and 1mL of N,N-dimethylformamide as an oil phase solution. Dissolve 50 mg of F127 in the above oil phase solution. Take 0.2mL of the above-prepared water phase and add it to 5mL of the above-prepared oil phase, stir (2000r / min) and mix for 20-40 minutes to form a W / O dispersion. The prepared W / O dispersion was electrospun using a single-needle electrospinning device with a voltage of 19kV, a flow rate of the dispersion of 0.4mL / h, and a receiving distance of 18cm. After 12 hours, a fiber film with a fiber diameter ...

Embodiment 2

[0025]Weigh 3 mg of thiolated chitosan with a weight average molecular weight of 100,000, 225 μg of polyethylene glycol diacrylate, and 300 μg of QK polypeptide were dissolved in 1 mL of phosphate buffer as the aqueous phase, and 3 mg of bovine serum albumin was added for protection. Weigh 800mg of PELCL and dissolve it in a mixed solvent of 4mL of chloroform and 1mL of N,N-dimethylformamide as an oil phase solution. Dissolve 45 mg of F127 in the above oil phase solution. Add 0.25mL of the above-prepared water phase to 5mL of the above-prepared oil phase, stir (2000r / min) and mix for 20-40 minutes to form a W / O dispersion. The prepared W / O dispersion was electrospun using a single-needle electrospinning device with a voltage of 16kV, a flow rate of the dispersion of 0.3mL / h, and a receiving distance of 16cm for electrospinning. After 12 hours, a fiber film with a fiber diameter of 400nm to 600nm was collected. , and its thickness is 100 μm to 200 μm. The actual loading capac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com