Electrostatic spinning fiber periodontal tissue regeneration material capable of carrying medicine and production method thereof

A periodontal tissue regeneration and electrospinning technology, applied in the field of medical materials, can solve problems such as increasing the recurrence rate of periodontal disease, achieve the effect of improving surgical efficacy and promoting tissue regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

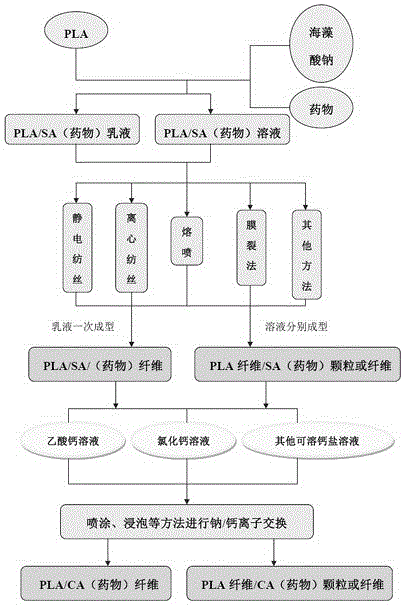

Method used

Image

Examples

Embodiment 1

[0044] Add 3% (mass ratio) of Span 80 to chloroform, emulsify at a high speed of 7000r / min for 20 minutes, add distilled water as a solvent to prepare sodium alginate with a mass fraction of 5% (sodium alginate, M w =2×10 5 g / mol) solution, high-speed emulsification at 7000r / min for 20min, adding polylactic acid (M w =3×10 5 g / mol), prepared into a 10% emulsion, stirred for 5h, and stood for 4h. The prepared polylactic acid / sodium alginate emulsion was formed by electrospinning to prepare polylactic acid / sodium alginate composite fiber membrane. The distance between the receiving plate and the needle is about 15 cm, spinning and forming at a voltage of 18 kV, and drying the formed fiber mat in vacuum to obtain a sodium alginate-polylactic acid film. Dissolve calcium chloride in distilled water to make a 5% calcium chloride solution. Preparation of calcium alginate-polylactic acid composite film: the distance between the receiving plate and the needle is about 10cm, the vol...

Embodiment 2

[0046] Add 1% Tween 60 to a mixed solvent of dimethylacetamide: dichloromethane (1:2), emulsify at a high speed of 3000r / min for 30 minutes, add water as a solvent to prepare alginic acid with a mass fraction of 4% Sodium (M w =9×10 6 g / mol) solution, high-speed emulsification at 5000r / min for 2h, adding polylactic acid (M w =6×10 5 g / mol), formulated into a 14% emulsion, stirred for 5h, and stood for 4h. The ZnO drug is added during the preparation of the sodium alginate solution to form a drug-loading system. The prepared polylactic acid / sodium alginate emulsion is formed by centrifugal electrospinning to prepare polylactic acid / sodium alginate composite fiber membrane. The distance between the receiving plate and the needle is about 20cm, and the spinning is formed at a voltage of 35kV. The centrifugal rotation speed 400r / min, vacuum drying to obtain sodium alginate-polylactic acid film. Dissolve calcium chloride in distilled water to make a 5% calcium chloride solutio...

Embodiment 3

[0048] Add 10% PVA solution (15% concentration) to the chloroform solvent, emulsify at 3000r / min for 30 minutes, add a mixed solvent of sodium hydroxide / urea / thiourea to prepare seaweed with a mass fraction of 15% Sodium acid (M w =1×10 4 g / mol) solution, high-speed emulsification at 5000r / min for 2h, adding polylactic acid (M w =9×10 7 g / mol), formulated into a 20% emulsion, stirred for 5h, and stood for 4h. Wherein the sodium alginate solution is prepared by adding lactoferrin to form a drug loading system. The prepared polylactic acid / sodium alginate emulsion was freeze-dried to prepare a polylactic acid / sodium alginate composite material, and dried in a vacuum to obtain a sodium alginate-polylactic acid film. Dissolve calcium chloride in distilled water to make a 5% calcium chloride solution. Preparation of calcium alginate-polylactic acid composite film: the distance between the receiving plate and the needle is about 10cm, the voltage between the needle and the rece...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com