Nickel-hydrogen power battery and preparation method therefor

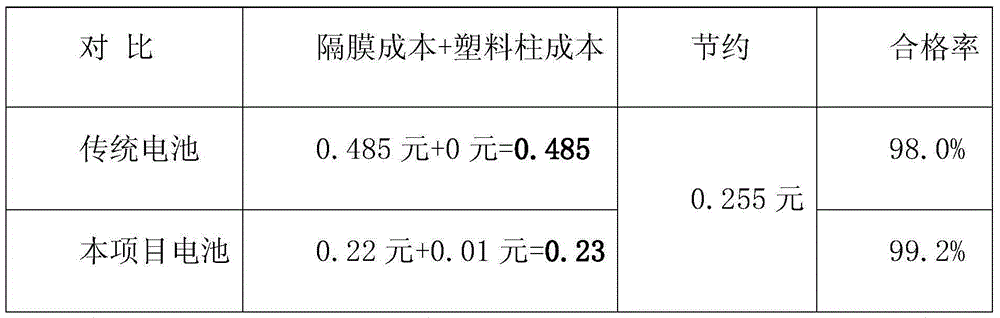

A power battery, nickel-hydrogen technology, applied in the field of electrochemistry, can solve the problems of low qualification rate, large battery self-discharge, unfavorable chemical reaction of active substances, etc., and achieve the effect of improving composite ability and anti-oxidation ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The active material of the positive electrode is 70.19g of nickel hydroxide crystal, the content of cobalt coated on the surface of nickel hydroxide is 15.31g, 4.50g of zinc, 1.5g of cobalt, 5.6g of cobalt hydroxide, and 0.9g of ytterbium oxide. The positive electrode substrate is foamed nickel.

[0036] The negative electrode substrate adopts superconducting copper mesh, and the copper mesh has a three-dimensional structure. The negative electrode hydrogen storage alloy powder is composed of 34.5g of molybdenum, 53.0g of nickel, 6.5g of cobalt, 5.0g of manganese, 1.0g of aluminum and 0.5g of additives. The additives are cerium: praseodymium : Superconducting carbon black is composed of 0.5-1:0.5;

[0037] The electrolyte contains 6% KOH solution, 22% NaOH solution, and 2% NaLiOH solution.

[0038] The positive electrode manufacturing step comprises the following sub-steps:

[0039] a1: positive electrode material preparation: uniformly mix the positive electrode activ...

Embodiment 2

[0051] The positive electrode active material is nickel hydroxide crystal 74.57g, the nickel hydroxide surface coating cobalt content is 14.23g, zinc 4.0g, cobalt 0.7g, the positive electrode active material adds ultra-low temperature active agent 8.5g, ultra-low temperature active agent is cobalt hydroxide, oxide Ytterbium, and cobalt hydroxide: ytterbium oxide is 5-6:0.5-1, the positive electrode substrate is foamed nickel,

[0052] The negative electrode substrate adopts superconducting copper mesh, and the copper mesh has a three-dimensional structure. The negative electrode hydrogen storage alloy powder is composed of 34.5g of molybdenum, 53.0g of nickel, 6.5g of cobalt, 5.0g of manganese, 1.0g of aluminum and 0.5g of additives. The additives are cerium: praseodymium : Superconducting carbon black is composed of 0.5-1:0.5;

[0053] The electrolyte contains 6% KOH solution, 22% NaOH solution, and 2% NaLiOH solution.

[0054] The positive electrode manufacturing step compr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com