Carbon nano-tube preparation method

A carbon nanotube, acetate technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of uneven diameter of carbon nanotubes, unfavorable industrial production, and length of carbon nanotubes. uncontrollable issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] A method for preparing carbon nanotubes proposed by the present invention includes the following steps or operations.

[0022] In step 1, nitrate or acetate of Fe, Al, and Mg are used as raw materials, citric acid is used as complexing agent and pore-forming agent, and water is added and mixed to form a solution.

[0023] In one embodiment, this step can be specifically performed as follows: using nitrate or acetate of Fe, Al, and Mg as raw materials, using citric acid as a complexing agent and pore-forming agent, adding water and mixing to form a solution , wherein, the nitrate or acetate of Fe, the nitrate or acetate of Al, the nitrate or acetate of Mg, the molar ratio of these four kinds of substances of citric acid are Fe:Al:Mg=1: x:y, 0.1≤x≤3, 0.1≤y≤3; citric acid / (Fe+Al+Mg)=z, 1≤z≤3.

[0024] In step 2, the above solution is calcined to prepare a catalyst, the structural formula of which is FeAlxMgyO, x=0.1-3, y=0.1-3.

[0025] In one embodiment, this step can b...

Embodiment 1

[0030] Weigh 202kgFe(NO 3 ) 3 9H 2 O, 318.86kgAl (NO 3 ) 3 9H 2 O, 12.82kgMg(NO 3 ) 2 9H 2 0, 537.99kg anhydrous citric acid, 720kg deionized water, pour into the reactor and stir to make it fully dissolved. 100°C oil bath heating, 85r / min mechanical stirring. Stir and heat to evaporate until the viscosity of the solution reaches 100mPas, then roast the solution in a tunnel kiln at 500°C under air atmosphere for 3 hours to obtain FeAl 1.7 Mg 0.1 o 4.15 catalyst.

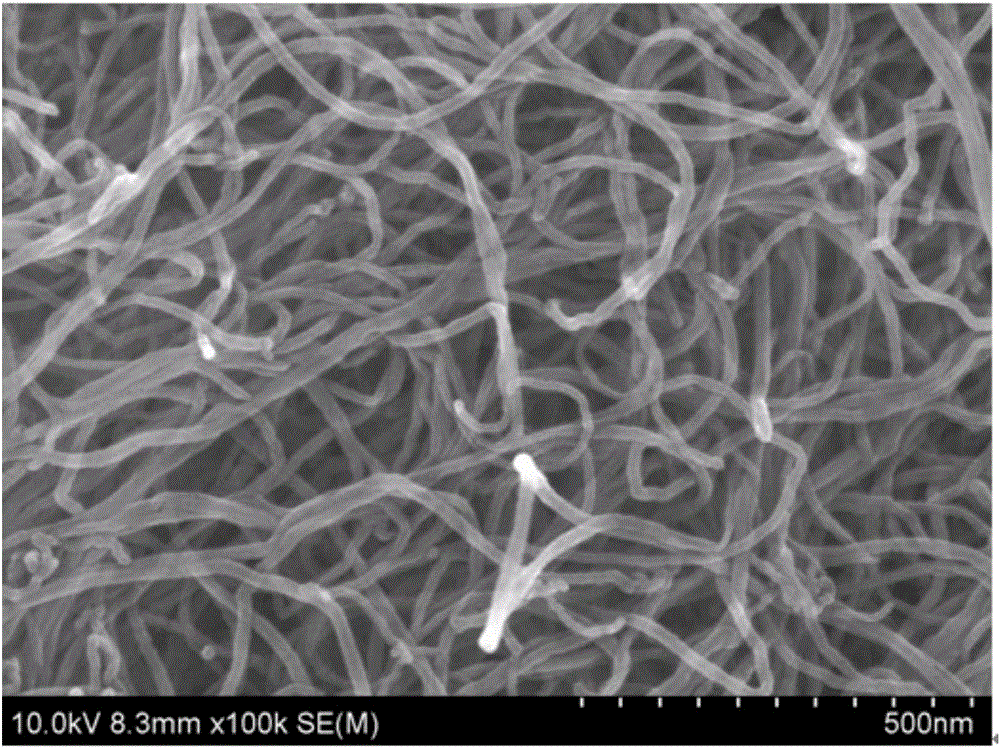

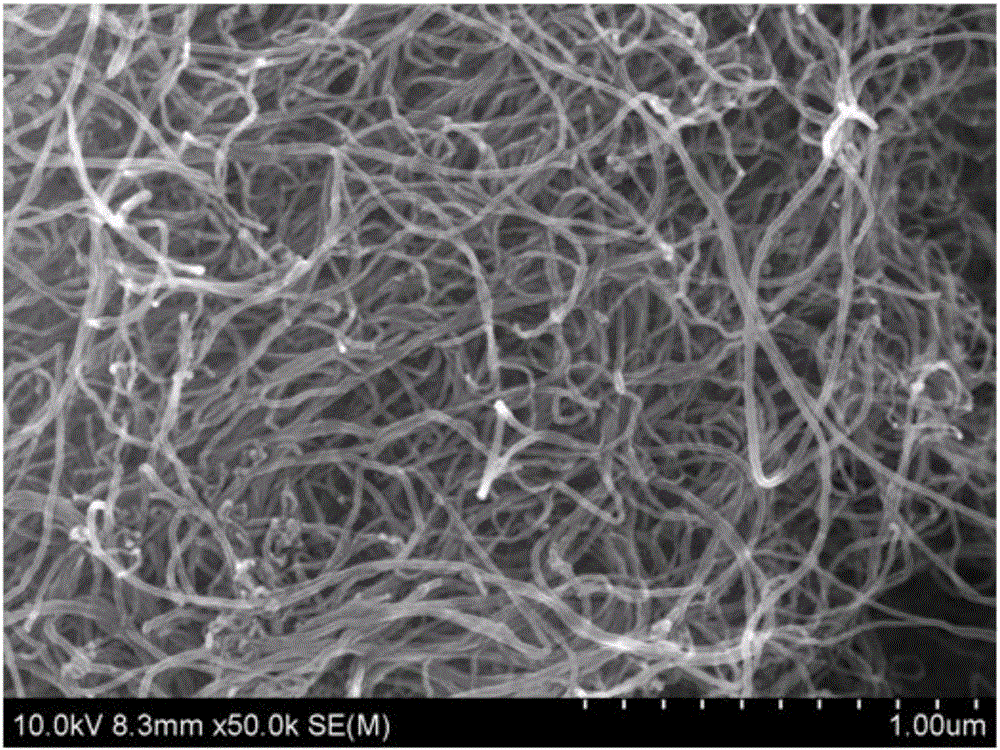

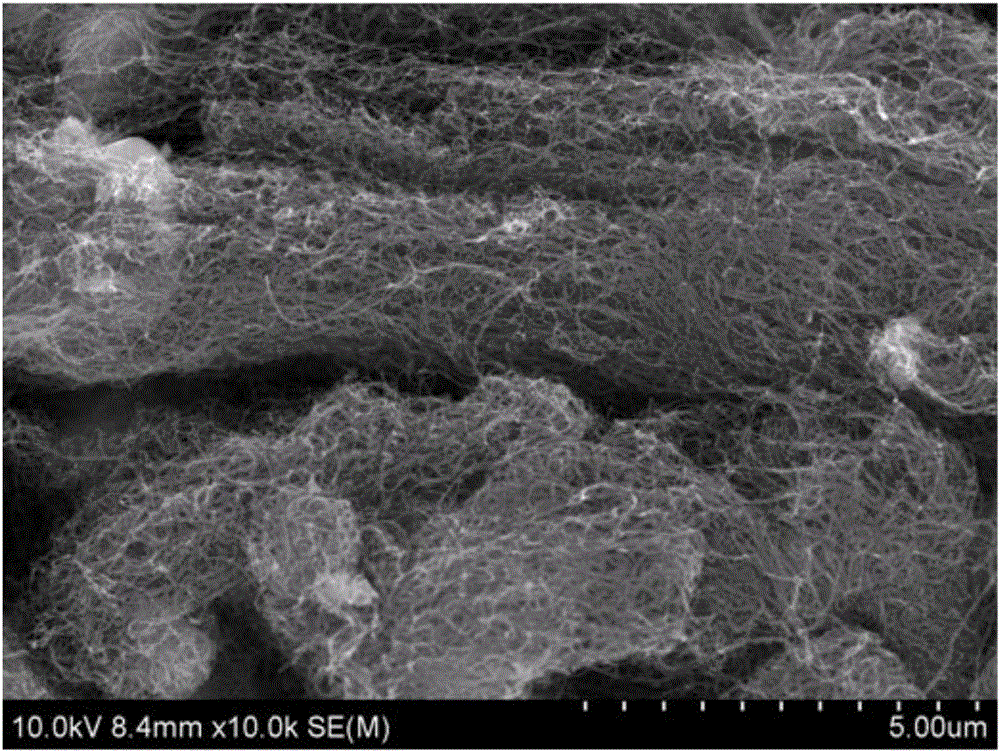

[0031] Use an automatic feeding system to push each crucible filled with 6g of catalyst powder continuously into the reaction zone of a tube furnace at 700°C, and adjust the ethylene flow rate by 5m 3 / h, hydrogen flow rate 1m 3 / h, set the program so that the residence time of each crucible in the reaction zone is 30min, push out the crucible and cool it under the protection of nitrogen atmosphere. see Figure 1-Figure 3 , figure 1 is made of FeAl1.7 Mg 0.1 o 4.15 A 100,000-fold scanning electron m...

Embodiment 2

[0034] Weigh 202kgFe(NO 3 ) 3 9H 2 O, 93.78kgAl(NO 3 ) 3 9H 2 O, 192.11kgMg (NO 3 )2·9H 2 O, 288.21kg anhydrous citric acid, 1620kg deionized water, pour into the reactor and stir to make it fully dissolved. 100°C oil bath heating, 85r / min mechanical stirring. Stir and heat to evaporate until the viscosity of the solution reaches 100mPas, then roast the solution in a tunnel kiln at 400°C under air atmosphere for 1 hour to obtain FeAl 0.1 Mg 1.5 o 3.15 catalyst.

[0035] Use an automatic feeding system to push each crucible filled with 6g of catalyst powder continuously into the reaction zone of a tube furnace at 500°C, and adjust the ethylene flow rate by 1m 3 / h, hydrogen flow rate 1m 3 / h, set the program so that the residence time of each crucible in the reaction zone is 20min, push out the crucible and cool it under the protection of nitrogen atmosphere. The yield of carbon nanotubes can be 2400%, the tube diameter is 15-20nm, and the ratio is 201-223㎡ / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com