Dry and hard particle forage for rams

A technology for forage and rams, applied in animal feed, animal feed, applications, etc., can solve the problems of unable to meet the growth needs of house-feeding sheep, doubtful palatability of formula components, unfavorable rumen internal environment stability, etc., to prevent digestive tract disease, improved feed palatability, improved immunity and reproductive capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

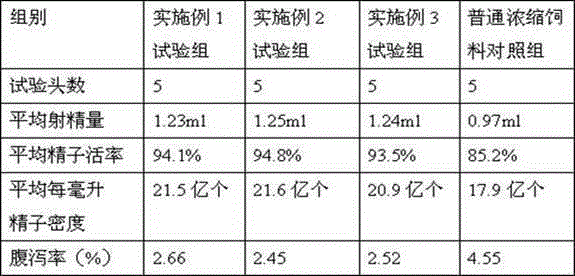

Examples

Embodiment 1

[0029] To prepare a kind of ram dry grain forage, first prepare raw materials: 335kg corn, 172kg soybean meal, 172kg dry wine residue powder, 133kg corn straw powder, 190kg alfalfa grass powder, 47kg fish meal, 95kg sweet potato dregs, 95kg oats, 95kg Chinese herbal medicine grass powder, Baking soda 9.5kg, calcium hydrogen phosphate 9.5kg, salt 9.5kg; its specific preparation method is as follows.

[0030] ⑴ Add 4kg of lysine and 1kg of phytase to 200kg of distiller's grains just out of the pot, mix them evenly, and then dry them in the sun. When the water content is lower than 12%, grind them into powder to obtain dry distiller's residue powder.

[0031] (2) Crush the natural sun-dried corn stalks with a water content lower than 12% into small sections of 8-15 mm in length and 0.5-2 mm in diameter to obtain corn stalk powder.

[0032] (3) Cut the natural sun-dried alfalfa with a water content lower than 12% into small pieces of 8-15 mm in length to obtain alfalfa powder.

...

Embodiment 2

[0038] To prepare a kind of ram dry grain forage, first prepare the raw materials: 350kg of corn, 180kg of soybean meal, 180kg of dry wine residue powder, 140kg of corn straw powder, 200kg of alfalfa grass powder, 50kg of fish meal, 100kg of sweet potato dregs, 100kg of oats, 100kg of Chinese herbal medicine grass powder, Baking soda 10kg, calcium hydrogen phosphate 10kg, salt 10kg; its specific preparation method is as follows.

[0039] ⑴Add 5kg of lysine and 1.2kg of phytase to 200kg of distiller's grains just out of the pot, mix them evenly, and then dry them in the sun. When the water content is lower than 12%, grind them into powder to obtain dry distiller's grains powder.

[0040] (2) Crush the natural sun-dried corn stalks with a water content lower than 12% into small sections of 8-15 mm in length and 0.5-2 mm in diameter to obtain corn stalk powder.

[0041] (3) Cut the natural sun-dried alfalfa with a water content lower than 12% into small pieces of 8-15 mm in lengt...

Embodiment 3

[0047] To prepare a kind of ram dry grain forage, first prepare raw materials: 365kg corn, 188kg soybean meal, 188kg dry wine residue powder, 147kg corn straw powder, 210kg alfalfa grass powder, 53kg fish meal, 105kg sweet potato dregs, 105kg oatmeal, 105kg Chinese herbal medicine grass powder, Baking soda 10.5kg, calcium hydrogen phosphate 10.5kg, salt 10.5kg; its specific preparation method is as follows.

[0048] ⑴ Add 6kg of lysine and 1.4kg of phytase to 200kg of distiller's grains just out of the pot, mix well and then dry them in the sun. When the water content is lower than 12%, grind them into powder to obtain dry distiller's residue powder.

[0049] (2) Crush the natural sun-dried corn stalks with a water content lower than 12% into small sections of 8-15 mm in length and 0.5-2 mm in diameter to obtain corn stalk powder.

[0050] (3) Cut the natural sun-dried alfalfa with a water content lower than 12% into small pieces of 8-15 mm in length to obtain alfalfa powder. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com