Maca dietary fiber as well as preparation method and application thereof

A technology of dietary fiber and maca, which is applied in the field of high-activity maca dietary fiber and its preparation, can solve the problems such as waste utilization of maca residues that are not mentioned

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

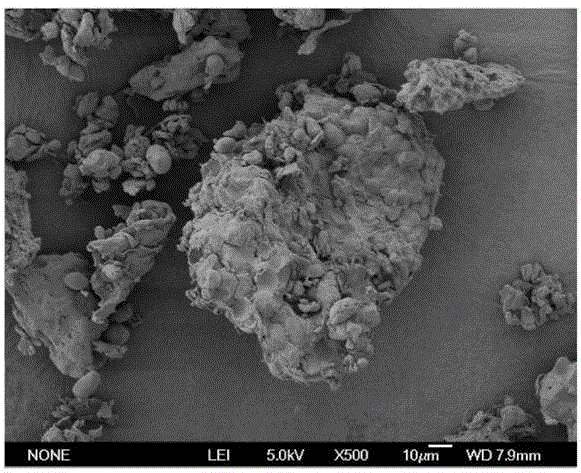

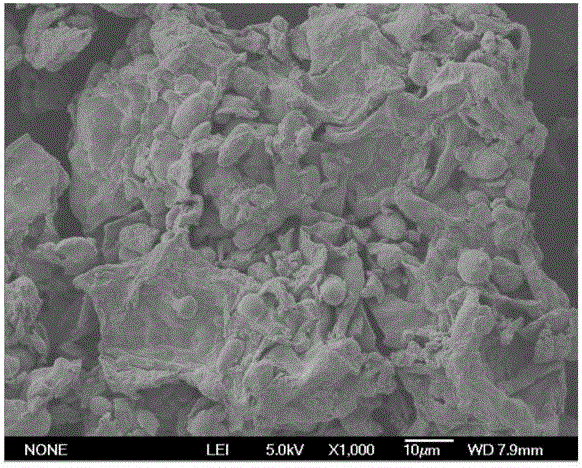

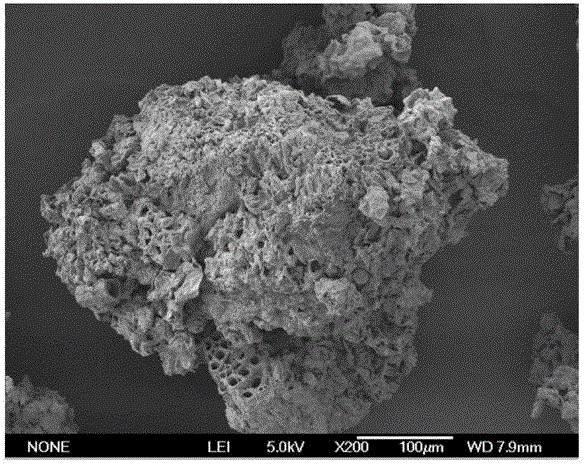

Image

Examples

Embodiment 1

[0061] (1) Raw material pulverization: pulverize maca root and pass through a 40-mesh sieve.

[0062] (2) Preparation: Weigh 100g of maca powder and add it to 500mL of water, add 200U / g of heat-stable α-amylase in a water bath at 90°C for 60min, cool to 30°C and then add 10U / g of For neutral protease, bathe in water at 30°C for 60 minutes, then add amyloglucosidase in an amount of 100 U / g, bathe in water at 30°C for 60 minutes.

[0063] (3) Separation and purification: add 4 volumes of 95% ethanol to the sample prepared in step (2) to precipitate overnight at room temperature, then wash with ethanol and acetone to obtain maca dietary fiber.

[0064] (4) Freeze drying.

[0065] Dietary fiber yield is 39.2% in the present embodiment.

Embodiment 2

[0067] (1) Crushing of raw materials: pulverizing the maca residue after water extraction and drying.

[0068] (2) Preparation: Weigh 100g of maca powder and add it to 5L of water, add 1000U / g of thermostable α-amylase in a water bath at 105°C for 20min, cool to 70°C and then add 100U / g of For neutral protease, bathe in water at 70°C for 20 minutes, then add amyloglucosidase in an amount of 600 U / g, bathe in water at 70°C for 60 minutes.

[0069] (3) Separation and purification: add 4 volumes of 95% ethanol to the sample prepared in step (2) to precipitate overnight at room temperature, then wash with ethanol and acetone to obtain maca dietary fiber.

[0071] Dietary fiber yield is 65.9% in the present embodiment.

Embodiment 3

[0073] (1) Raw material pulverization: maca residue after 50% ethanol extraction is pulverized.

[0074](2) Preparation: Weigh 100g of maca powder and add it to 1L of water, add 500U / g of heat-stable α-amylase in a water bath at 95°C for 30min, cool to 60°C and then add 40U / g of For neutral protease, bathe in water at 60°C for 30 minutes, then add amyloglucosidase in an amount of 250 U / g, bathe in water at 60°C for 30 minutes.

[0075] (3) Separation and purification: add 4 volumes of 95% ethanol to the sample prepared in step (2) to precipitate overnight at room temperature, then wash with ethanol and acetone to obtain maca dietary fiber.

[0076] (4) Air-dry at room temperature.

[0077] Dietary fiber yield is 45.5% in the present embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Swelling rate | aaaaa | aaaaa |

| Water holdup | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com