Slow-release and long-acting organic-inorganic compound fertilizer

A compound fertilizer, long-term technology, applied in the direction of fertilization device, fertilizer mixture, application, etc., can solve the problem of unsafe use of farmyard manure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

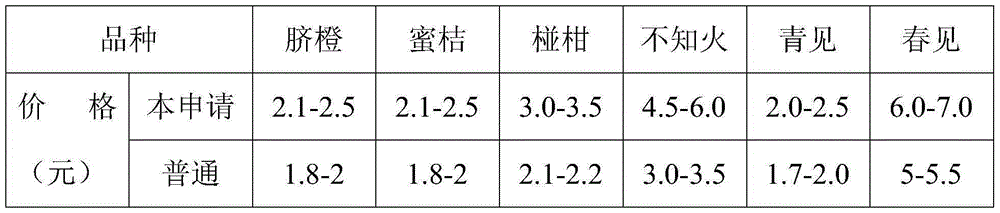

[0013] Example 1 Effect of slow-release and long-acting organic-inorganic compound fertilizer on the quality of different citrus varieties

[0014] A slow-release long-acting organic-inorganic compound fertilizer, which consists of the following components in parts by weight: 60-100 parts of urea, 125 parts of monoammonium phosphate, 25-50 parts of potassium chloride, and 25 parts of potassium sulfate -50 parts, humic acid 50-100 parts, calcium carbonate 5 parts, corn bran 50-100 parts, amino acid powder 20 parts, magnesium sulfate 25-50 parts, boric acid 20-50 parts, zinc sulfate monohydrate 20-30 parts. Among them, the amino acid powder is composed of aspartic acid, threonine, serine, glutamic acid, glycine, alanine, cystine, valine, methionine, isoleucine, leucine, tyrosine, benzene Alanine, Lysine, Histidine, Arginine, Proline, Aspartic Acid, Threonine, Serine, Glutamic Acid, Glycine, Alanine, Cystine, Valine, The weight ratio of methionine, isoleucine, leucine, tyrosine,...

Embodiment 2

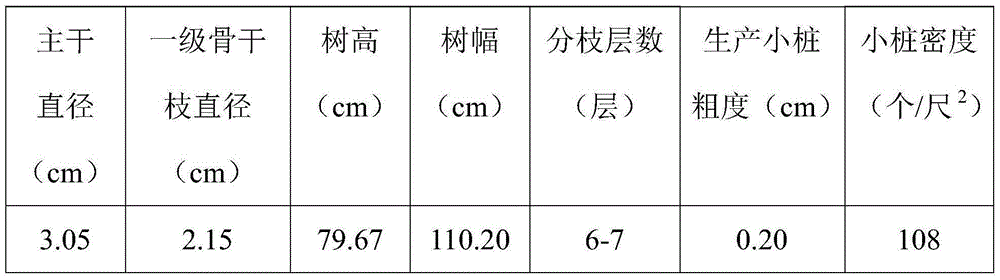

[0020] Example 2 Effect of slow-release and long-acting organic-inorganic compound fertilizer on Shiranui yield

[0021] A slow-release long-acting organic-inorganic compound fertilizer, which consists of the following components in parts by weight: 100 parts of urea, 125 parts of monoammonium phosphate, 50 parts of potassium chloride, 50 parts of potassium sulfate, humic acid 100 parts, 5 parts of calcium carbonate, 50 parts of corn bran, 20 parts of amino acid powder, 25 parts of magnesium sulfate, 20 parts of boric acid, 20 parts of zinc sulfate monohydrate. Among them, the amino acid powder is composed of aspartic acid, threonine, serine, glutamic acid, glycine, alanine, cystine, valine, methionine, isoleucine, leucine, tyrosine, benzene Alanine, Lysine, Histidine, Arginine, Proline, Aspartic Acid, Threonine, Serine, Glutamic Acid, Glycine, Alanine, Cystine, Valine, The weight ratio of methionine, isoleucine, leucine, tyrosine, phenylalanine, lysine, histidine, arginine a...

Embodiment 3

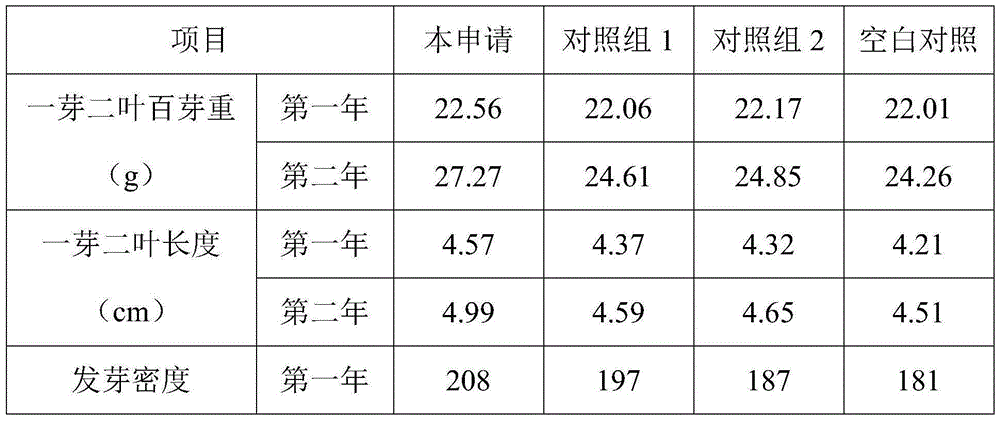

[0034] Example 3 Effect of Slow Release Long-acting Organic-Inorganic Compound Fertilizer on Ponkan Yield

[0035]A slow-release long-acting organic-inorganic compound fertilizer, which consists of the following components in parts by weight: 80 parts of urea, 125 parts of monoammonium phosphate, 25 parts of potassium chloride, 25 parts of potassium sulfate, humic acid 80 parts, calcium carbonate 5 parts, corn bran 60 parts, amino acid powder 20 parts, magnesium sulfate 25 parts, boric acid 20 parts, zinc sulfate monohydrate 20 parts. Among them, the amino acid powder is composed of aspartic acid, threonine, serine, glutamic acid, glycine, alanine, cystine, valine, methionine, isoleucine, leucine, tyrosine, benzene Alanine, Lysine, Histidine, Arginine, Proline, Aspartic Acid, Threonine, Serine, Glutamic Acid, Glycine, Alanine, Cystine, Valine, The weight ratio of methionine, isoleucine, leucine, tyrosine, phenylalanine, lysine, histidine, arginine and proline is 29:27:39:66:2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com