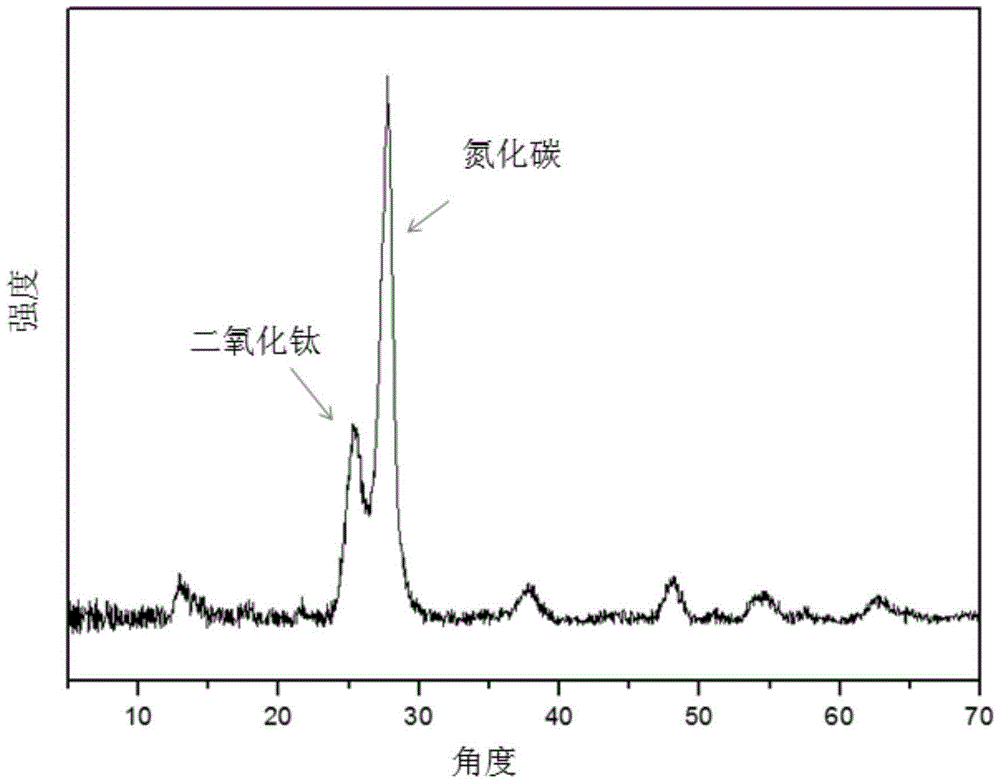

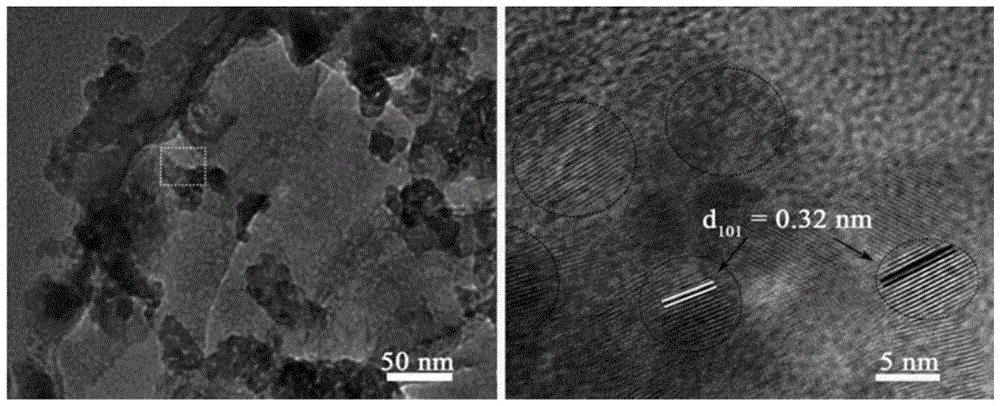

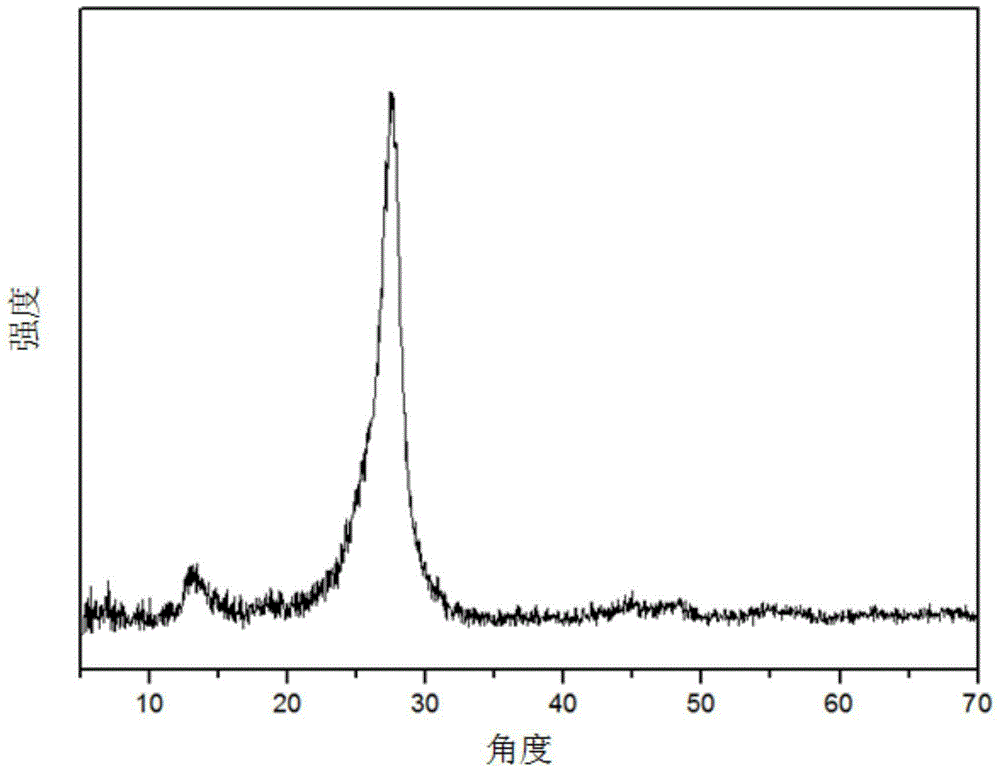

Titanium dioxide-boron modified carbon nitride catalyst and preparation method thereof

A titanium dioxide and boron modification technology, applied in physical/chemical process catalysts, hydrocarbon production from carbon oxides, chemical instruments and methods, etc., can solve problems such as poor catalytic effect, low utilization rate of sunlight, and small specific surface area. Achieve the effect of increasing the specific surface area, high utilization rate of visible light, and improving the separation of charges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0034] Specific embodiment one: the preparation method of highly active titanium dioxide-boron modified carbon nitride photocatalyst in this embodiment is specifically completed according to the following steps:

[0035] 1. Preparation of boron carbon nitrogen aqueous solution: under the condition of temperature of 25-35°C, completely dissolve the boron salt in deionized water, and configure it into an aqueous solution of boron salt with a molar concentration of 0.001mol / L-0.1mol / L, and stir Stir at a speed of 100r / min to 300r / min for 10min to 30min, then add 1-3g of carbon and nitrogen sources and continue stirring to obtain an aqueous solution of boron, carbon and nitrogen; 2. Preparation of boron-modified carbon nitride: the above step 1 The boron carbon nitrogen aqueous solution is placed in an electric blast drying oven at 80-120°C and evaporated to dryness to obtain a boron carbon nitrogen precursor powder. After the precursor is roasted in a muffle furnace at 200-400°C f...

specific Embodiment approach 2

[0040] Specific embodiment two: the difference between this embodiment and specific embodiment one or two is: the boron salt described in step one is 1-butyl-3-methylimidazolium tetrafluoroborate, boron trifluoride Diethyl ether, triphenylphosphineborane, tetrabutylammonium borohydride, sodium triacetoxyborohydride and 1,3,5-trimethyl-4-(4,4,5,5-tetramethyl-1 , 3,2-dioxaborolan-2-yl)-1H-pyrazole or a mixture of several of them. Others are the same as those in Embodiment 1 or 2.

specific Embodiment approach 3

[0041] Embodiment 3: This embodiment is different from Embodiment 1 in that the carbon and nitrogen source described in step 1 is urea, melamine and dicyandiamide or a mixture of several of them. Others are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com