Copper-containing ammoxidation catalyst and preparation method thereof

A catalyst and ammonia oxidation technology, applied in the field of nitrogen oxides, to achieve the effects of simple process, less leakage and excellent ammonia purification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

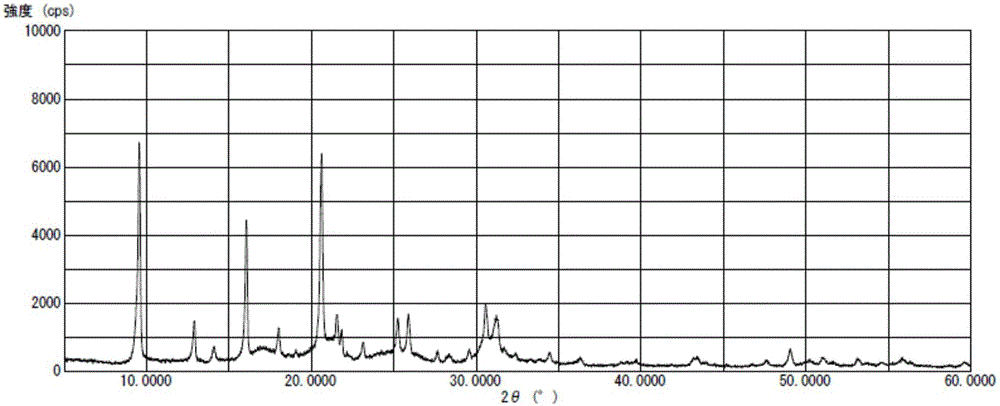

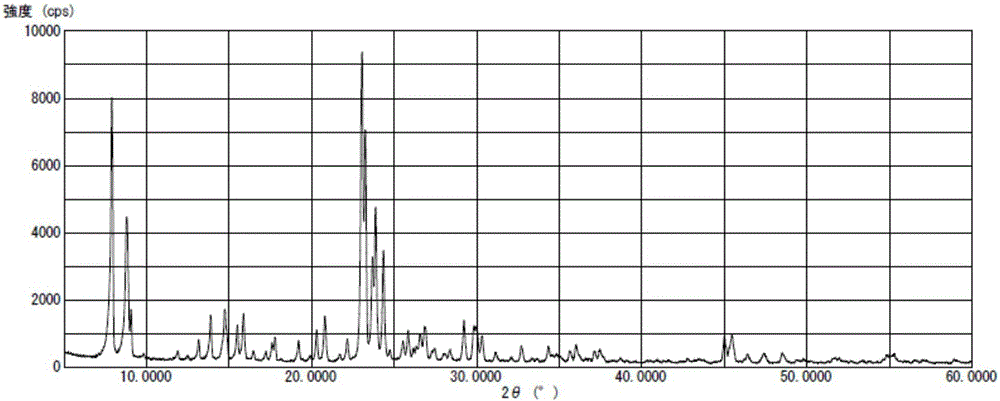

Image

Examples

preparation example Construction

[0043] The synthetic zeolite in the preparation of the ammoxidation catalyst of the present invention must be a solid acid formed by hydrogenation (protonation) by firing treatment after ion-exchanging the alkali metal of the synthetic zeolite structure with ammonia, nitric acid or hydrochloric acid, etc. Zeolites were synthesized by hydrogenation of points (Bronsted acid moieties, and Lewis acid moieties). The calcining temperature is above 350°C, preferably a hydrogenated synthetic zeolite obtained by heating at 500-700°C.

[0044] catalyst metal

[0045] The raw material for carrying copper (II) ions is preferably copper (II) nitrate or hydrochloride, especially nitrate is more ideal.

[0046] metal bearing

[0047] As the metal loading method for synthesizing zeolite, methods such as ion exchange method, impregnation loading method, evaporation drying method, precipitation loading method, physical mixing method, and skeleton replacement method are usually used.

[0048]...

Embodiment 1

[0087] AMMOXIDATION CATALYSTS FOR COPPER(Ⅱ)-SUPPORTED COPPER(Ⅱ)-SUPPORTED CHA HYDROGENED CHA SYNTHESIZED ZEOLITES

[0088] Example 1 A silicoaluminophosphate-based hydrogenated CHA-type synthetic zeolite was loaded with copper (II) ions to obtain an ammoxidation catalyst.

[0089] Adjustment of zeolite raw material

[0090] First, ion-exchanged water and 85 wt% orthophosphoric acid were stirred and mixed in a glass container. Here, pseudo-boehmite (PuralSB) was added and stirred at room temperature for 20 minutes. Next, the morpholine was slowly added with stirring and allowed to reach room temperature for 1 hour. Afterwards, add colloidal silicon dioxide (LudoxAS40), continue to stir for 5 minutes, become the suspension of pH8.1, prepare 1.0 (Al 2 o 3 ): 1.06 (P 2 o 5 ): 1.08 (SiO 2 ): 2.09(R): 66(H 2 O) composition.

[0091] hydrothermal synthesis

[0092]The resulting suspension was transferred to an autoclave (autoclave) with a stirrer, sealed, heated at 170° C. ...

Embodiment 2

[0101] Embodiment 2 except adjusting to 2.3g copper nitrate (II) 3 hydrates (Cu(NO 3 ) 2 ·3H 2 Except for O), the others were the same as in Example 1 to obtain a hydrogenated CHA-type synthetic zeolite supporting copper (II). Its average particle diameter (D50) was 7 μm. According to the analysis result of ICP, the content of copper (II) was 3.8 wt%. In addition, as in Example 1, the slurry was coated on a honeycomb carrier made of cordierite at a load of 270 g / L to obtain the ammoxidation catalyst of Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com