Method for preparing glutathione by means of enzymic method

A technology for glutathione and enzymatic preparation, which is applied in fermentation and other directions, can solve the problems of increased difficulty in purification, and achieve the effects of saving reaction time, reducing production costs, and reducing ATP consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

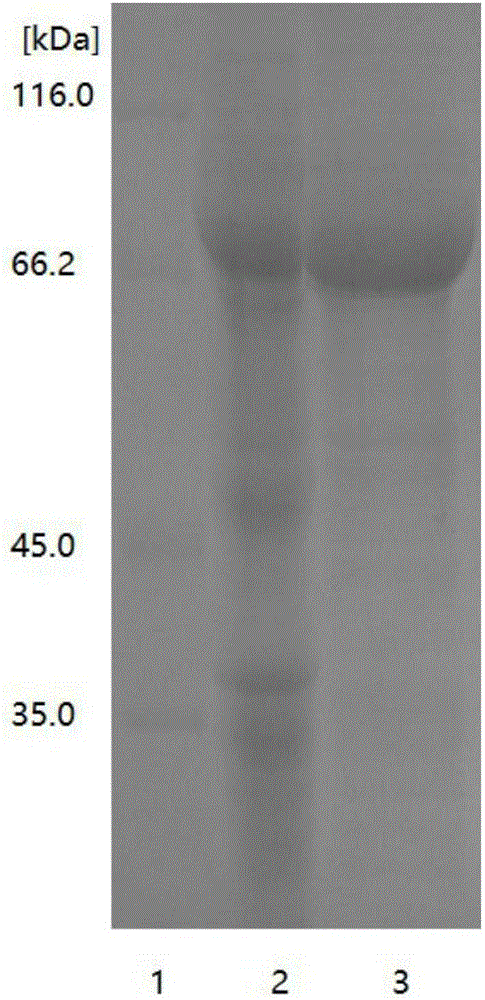

[0060] The preparation of embodiment 1GshF enzyme

[0061] The GshF enzyme in the method of the present invention can be obtained commercially, or it can be artificially modified to have the same catalytic function.

[0062] The preparation process of GshF enzyme is as follows:

[0063] According to the GshF gene sequence (GenBank: NC_008532), a pair of amplification primers were designed and synthesized by Zhongmei Taihe Biotechnology Co., Ltd. The primer sequences are as follows:

[0064] GshF sense primer: 5'-CCATATGACATTAAACCAACTTCTTCAAAAACTG-3'; and

[0065] GshF antisense primer: 5'-CGAATTCTTAAGTTTGACCAGCCACTATTTC-3';

[0066] Extract the DNA of Streptococcus thermophilus (CGMCC1.6472) strain (CGMCC1.6472), use it as a template, amplify the gshF gene fragment by PCR, and connect it to the pET22b vector (purchased from Invitrogen Company) respectively, after the sequence is correct, They were transferred into E.coliBL21 (DE3) strain (purchased from Tiangen Biochemical ...

Embodiment 2

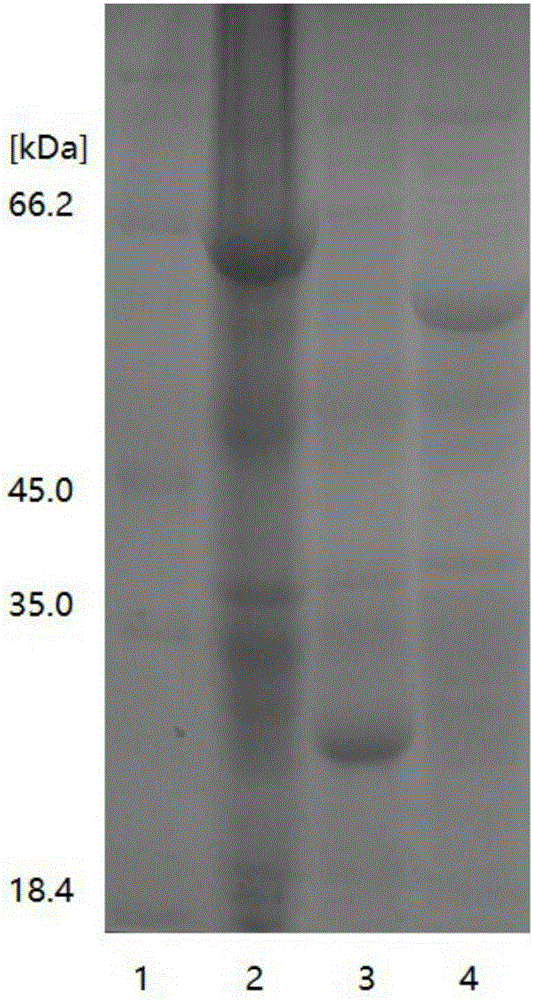

[0073] The preparation of embodiment 2Ppk, Adk and Pap enzyme

[0074] The Ppk, Adk and Pap enzymes in the method of the present invention can be obtained commercially, or are artificially modified enzymes having the same catalytic function.

[0075] The preparation process of Ppk, Adk and Pap enzyme is as follows:

[0076] According to the GshF gene sequence (GenBank: NC_008532), three pairs of amplification primers were designed and synthesized by Zhongmei Taihe Biotechnology Co., Ltd. The primer sequences are as follows:

[0077] ppk sense primer: 5'-CCATATGGGTCAGGAAAAGCTATACATCG-3';

[0078] ppk antisense primer: 5'-CGGATCCTTTATTCAGGTTGTTCGAGTGATT-3';

[0079] adk sense primer: 5'-CCATATGCGTATCATTCTGCTTGGCGCTCCGG-3';

[0080] ADK antisense primer: 5'-CGGATCCTTAGCCGAGGATTTTTTTCCAGATC-3';

[0081] PAP sense primer: 5'-GCCATGGATACAGAAACGATCGCCAGTGCAG-3'; and

[0082] pap antisense primer: 5'-CGGATCCTTAATCCGTGTCGCGATCCGCTT-3';

[0083] Extract the DNA of Escherichia coli...

Embodiment 3

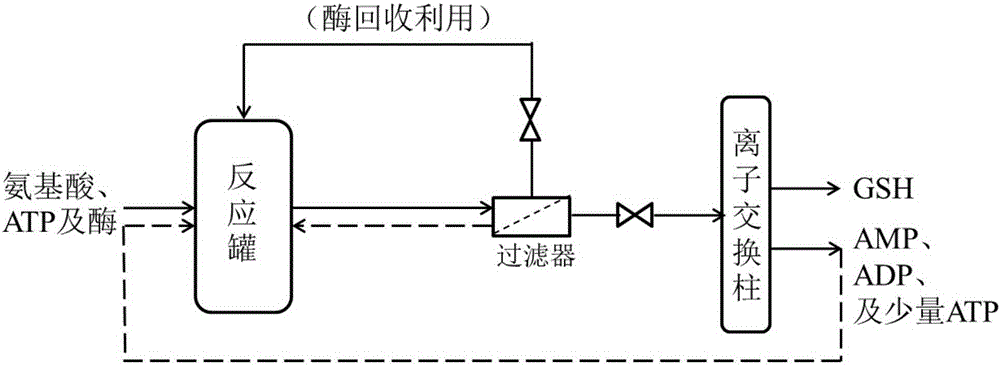

[0090] Embodiment 3 uses free enzyme to prepare glutathione

[0091] image 3 Process flow diagram for the preparation of GSH using free enzymes for the process of the present invention. see image 3 , prepare GSH according to the process flow diagram of the present invention and use free enzyme to prepare glutathione according to the following steps:

[0092] (1) Generate glutathione GSH in the reaction tank:

[0093]In the reaction tank, the reaction system of 100L sterile water contains substrates 800g glutamic acid, 800g cysteine and 600g glycine, as well as 2000g ATP, 600g disodium hydrogen phosphate, 1100g potassium chloride, 870g sodium chloride and 800g Magnesium chloride solution, potassium hydroxide is added to adjust the pH to about 7.0, and 100 g of GshF enzyme solution is added to the reaction system to start the reaction. During the reaction, the pH value is controlled to be 6.5-7.5, and the temperature is 35-38°C.

[0094] (2) Regenerate ATP in the reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com