Anode material of lithium ion battery and preparation method of anode material

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as poor cycle performance, large rebound of pole pieces, and low specific capacity, and achieve low cost, increased capacity, and high specific capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Add 20g polyvinyl alcohol organic polymer into 2L water and stir for 30 minutes;

[0020] (2) Add 200g of natural spherical graphite A into the solution containing polyvinyl alcohol and stir for 30 minutes;

[0021] (3) Add 34.0g copper chloride dihydrate into the above water solvent, and stir for half an hour;

[0022] (4) While stirring, add 1000mL, 0.4mol / L sodium hydroxide dropwise at 5mL / min to the mixed solution, and stir for 2 hours;

[0023] (5) Filter the above solution, and dry the precipitate at 100°C for 5 hours; under the protection of argon gas, heat treatment at 700°C, and naturally cool to 200°C, then let the material cool naturally under oxygen or air conditions, The lithium ion battery negative electrode material can be obtained.

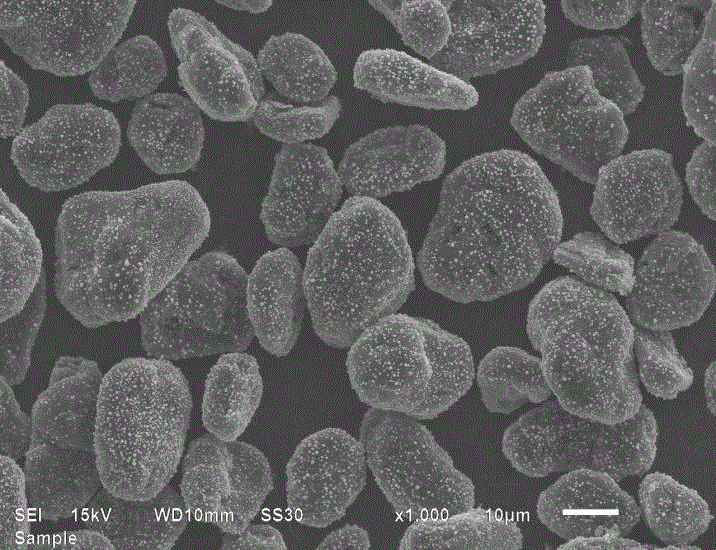

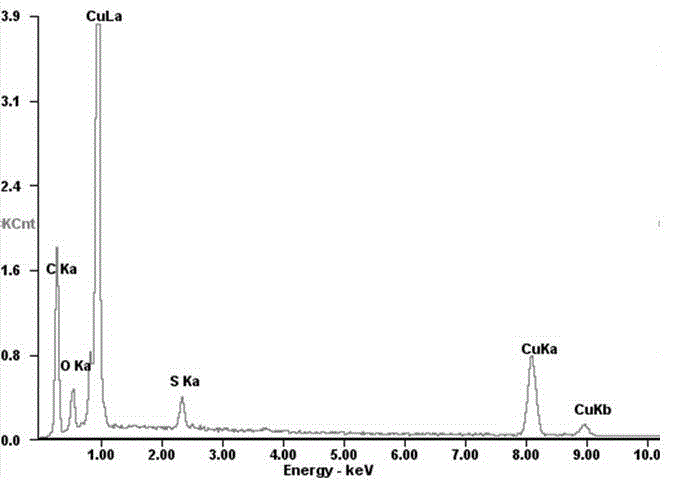

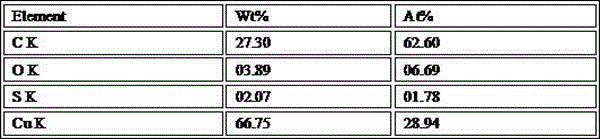

[0024] from figure 1 It can be seen from the electron microscope photos in the graph that the surface of the graphite material is covered with a layer of nanoparticles. Using the EDS spectrum ( figure 2 ) and Table ...

Embodiment 2

[0028] (1) Add 10g polyvinyl alcohol organic polymer into 2L water and stir for 30 minutes;

[0029] (2) Add 300g of artificial graphite B into the solution containing polyvinyl alcohol and stir for 30 minutes;

[0030] (3) Add 50.0g of copper sulfate pentahydrate into the above water solvent and stir for half an hour;

[0031] (4) While stirring, add 1000mL, 0.2mol / L potassium hydroxide dropwise at 5mL / min to the mixed solution, and stir for 2 hours;

[0032] (5) Filter the above solution, and dry the precipitate at 100°C for 5 hours; under the protection of argon gas, heat treatment at 700°C, and naturally cool to 200°C, then let the material cool naturally under oxygen or air conditions, The lithium ion battery negative electrode material can be obtained.

Embodiment 3

[0034] (1) Add 15g polyvinylpyrrolidone organic polymer into 2L water and stir for 30 minutes;

[0035] (2) Add 200g of natural spherical graphite C into the solution containing polyvinyl alcohol and stir for 30 minutes;

[0036] (3) Add 36.3g of copper nitrate trihydrate into the above water solvent and stir for half an hour;

[0037] (4) While stirring, add 1000mL, 0.3mol / L ammonium carbonate dropwise at 3mL / min to the mixed solution, and stir for 2 hours;

[0038] (5) Filter the above solution, and dry the precipitate at 100°C for 5 hours; under the protection of argon gas, heat treatment at 700°C, and naturally cool to 200°C, then let the material cool naturally under oxygen or air conditions, The lithium ion battery negative electrode material can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com