Process for producing olefin from methanol and for co-producing gasoline and aromatic hydrocarbon

A technology for producing olefins and aromatics from methanol, which is applied in the petroleum industry, ethylene production, and hydrocarbon production from oxygen-containing organic compounds. The effect of achieving zero emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

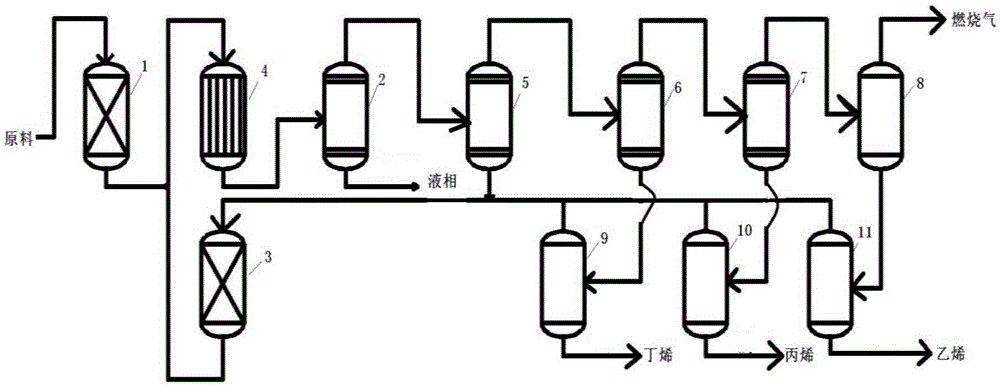

Method used

Image

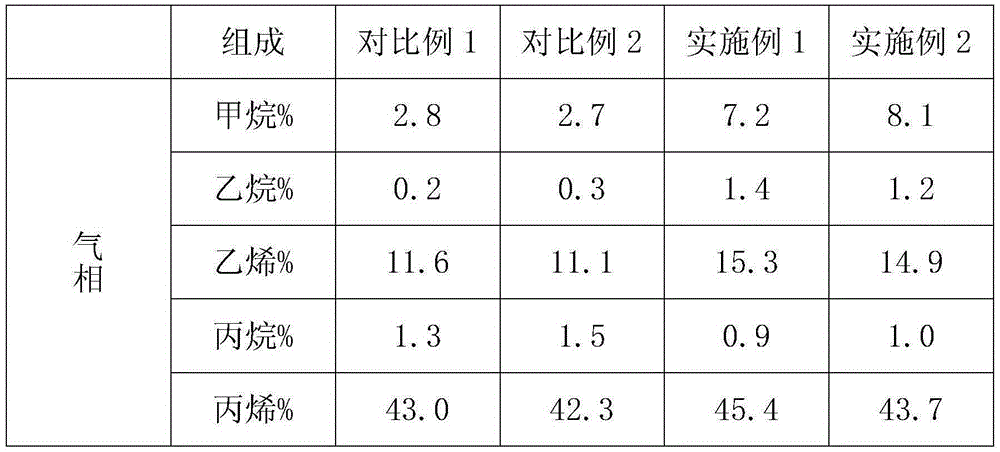

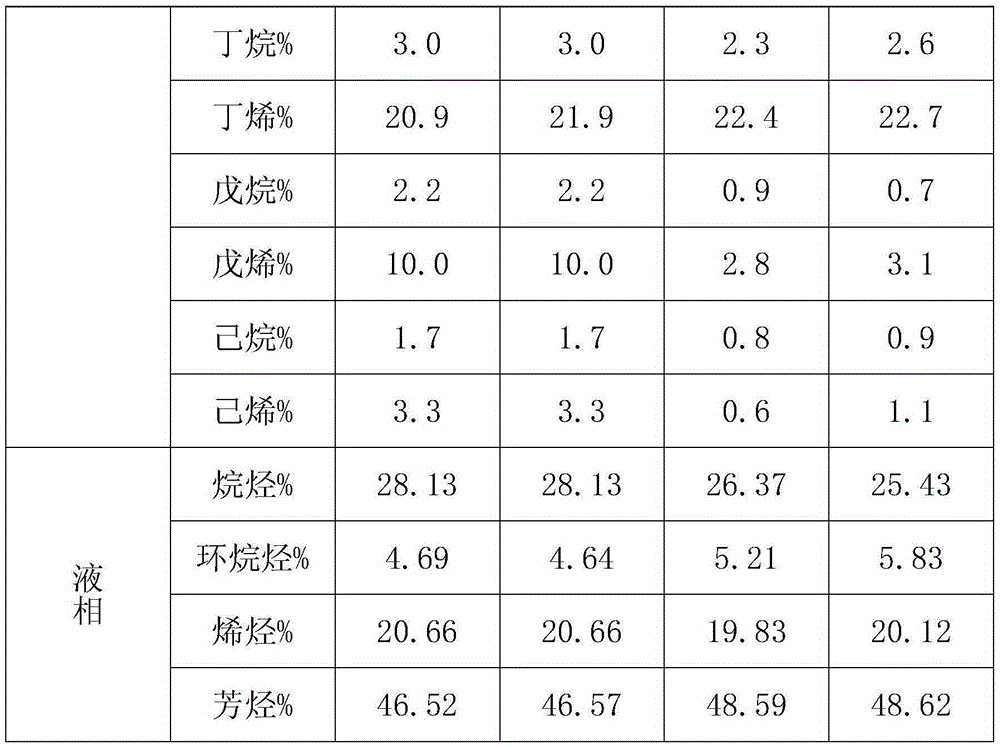

Examples

Embodiment 1

[0033] Catalyst preparation

[0034] Mix the commercially available HZM-5 molecular sieve, alumina, scallop powder, water and nitric acid, stir evenly, shape, and dry naturally, then dry at 120°C for 3h, and finally in the muffle furnace from room temperature at 5°C / min Rise to 550°C and keep it for 3 hours to obtain a pretreatment catalyst; the mass ratio of HZM-5 molecular sieve to alumina is 7:3, the mass of kale powder added is 2.9% of the mass of HZM-5 molecular sieve, and the mass of water added is HZM 75% of the mass of -5 molecular sieve, and the added mass of nitric acid is 2.3% of the mass of HZM-5 molecular sieve.

[0035] With described pretreatment catalyst 15g, impregnate in the mixed solution of 7.5ml potassium nitrate (0.001mol / mL and calcium nitrate (0.02mol / mL), let stand 24h, dry naturally, then dry 3h at 120 ℃, finally in In the muffle furnace, the temperature was raised from room temperature to 550° C. at 5° C. / min and kept for 3 hours to obtain the MTO c...

Embodiment 2

[0042] Catalyst preparation

[0043] Mix the commercially available HZM-5 molecular sieve, alumina, scallop powder, water and nitric acid, stir evenly, shape, and dry naturally, then dry at 120°C for 3h, and finally in the muffle furnace from room temperature at 5°C / min Rise to 550°C and keep it for 3 hours to obtain a pretreatment catalyst; the mass ratio of HZM-5 molecular sieve to alumina is 6:4, the mass of kale powder added is 2.5% of the mass of HZM-5 molecular sieve, and the mass of water added is HZM 70% of the quality of -5 molecular sieve, the quality of adding nitric acid is 2% of the quality of HZM-5 molecular sieve.

[0044] 15g of the pretreatment catalyst was impregnated in a mixed solution of 7.5mL potassium nitrate (0.001mol / mL), calcium nitrate (0.02mol / mL), lanthanum nitrate (0.001mol / mL), cerium nitrate (0.001mol / mL) In the middle, let stand for 24h, dry naturally, then dry at 120°C for 3h, and finally raise from room temperature to 550°C at 5°C / min in a m...

Embodiment 3

[0051] Catalyst preparation

[0052] Mix the commercially available HZM-5 molecular sieve, alumina, scallop powder, water and nitric acid, stir evenly, shape, and dry naturally, then dry at 120°C for 3h, and finally in the muffle furnace from room temperature at 5°C / min Rise to 550°C and keep it for 3 hours to obtain a pretreatment catalyst; the mass ratio of HZM-5 molecular sieve to alumina is 5:3, the mass of kale powder added is 2.4% of the mass of HZM-5 molecular sieve, and the mass of water added is HZM 45% of the mass of -5 molecular sieve, and the added mass of nitric acid is 3% of the mass of HZM-5 molecular sieve.

[0053] 15g of the pretreatment catalyst was impregnated in 7.5mL of potassium nitrate (0.001mol / mL) solution, left to stand for 24h, dried naturally, then dried at 120°C for 3h, and finally in a muffle furnace from room temperature to 5°C / min increased to 550°C and kept for 3h to obtain an MTO catalyst.

[0054] 15g of the pretreatment catalyst was impr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com