Cardanol based epoxy resin containing maleimide structure and preparation method of cardanol based epoxy resin

A cardanol-based epoxy resin, maleimide technology, applied in the direction of organic chemistry, can solve the problems of low water absorption, low crosslinking density, low glass transition temperature, etc., and achieves heat and humidity resistance and adhesive properties Excellent, easy to operate, excellent overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

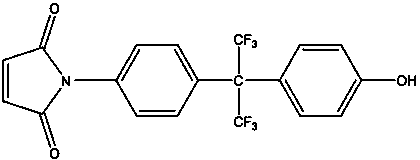

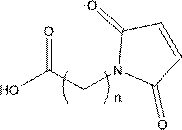

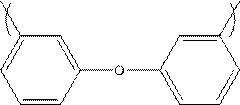

[0037] (1) Under the protection of nitrogen, add 7.94 g (0.042 mol) of N-p-hydroxyphenylmaleimide to 6.00 g (0.02 mol) of cardanol (molecular weight: 300), and keep the temperature at 200°C under the protection of nitrogen . N-p-hydroxyphenylmaleimide melts gradually, forms a uniform solution with cardanol, and continues to react for 8 hours under stirring. After the reaction was completed, it was cooled to room temperature to obtain 13.94 g of cardanol (CA-2.1HPM) containing N-p-hydroxyphenylmaleimide structure.

[0038] (2) Under the protection of nitrogen, heat and stir 2.25 grams of CA-2.1HPM, 20 milliliters of epichlorohydrin and 10 milliliters of isopropanol to form a homogeneous phase, add 1.5 grams of anhydrous potassium carbonate, and reflux at 120 ° C for 10 hours . The reaction system gradually changed from dark red to dark purple. After the reaction was completed, after the solution was cooled to room temperature, it was extracted and washed three times with 100...

Embodiment 2

[0042](1) Under the protection of nitrogen, add 5.67 g (0.03 mol) of N-p-hydroxyphenylmaleimide to 9.00 g (0.03 mol) of cardanol (molecular weight: 300), and keep the temperature at 200°C under the protection of nitrogen . N-p-hydroxyphenylmaleimide melts gradually, forms a uniform solution with cardanol, and continues to react for 8 hours under stirring. After the reaction was completed, it was cooled to room temperature to obtain 14.67 g of cardanol (CA-1HPM) containing N-p-hydroxyphenylmaleimide structure.

[0043] (2) Under the protection of nitrogen, 2.44 g of CA-1HPM, 20 ml of epichlorohydrin and 10 ml of isopropanol were heated and stirred to dissolve into a homogeneous phase, and 1.5 g of anhydrous potassium carbonate was added, and the reaction was refluxed at 120 ° C for 10 hours. The reaction system gradually changed from dark red to dark purple. After the reaction was completed, after the solution was cooled to room temperature, it was extracted and washed three ...

Embodiment 3

[0047] (1) Under the protection of nitrogen, add 7.94 g (0.042 mol) of N-p-hydroxyphenylmaleimide to 6.00 g (0.02 mol) of cardanol (molecular weight: 300), and keep the temperature at 180°C under the protection of nitrogen . N-p-hydroxyphenylmaleimide melts gradually, forms a homogeneous solution with cardanol, and continues to react for 12 hours under stirring. After the reaction was completed, it was cooled to room temperature to obtain 13.94 g of cardanol (CA-2.1HPM) containing N-p-hydroxyphenylmaleimide structure.

[0048] (2) Under the protection of nitrogen, heat and stir 2.25 g of CA-2.1HPM, 20 ml of epichlorohydrin and 10 ml of isopropanol to dissolve into a homogeneous phase, add 1.5 g of sodium hydroxide, and reflux at 120 ° C for 10 hours. The reaction system gradually changed from dark red to dark purple. After the reaction was completed, after the solution was cooled to room temperature, it was extracted and washed three times with 100 ml of deionized water. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com