Processing method of dried crab meat floss with low allergy

A hypoallergenic, processing method technology, applied in food science and other fields, can solve problems affecting food safety and health, and achieve the effect of being suitable for large-scale production, low allergenicity, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: the processing method of hypoallergenic crabmeat floss

[0036] A kind of processing method of hypoallergenic crab floss, it comprises the following steps:

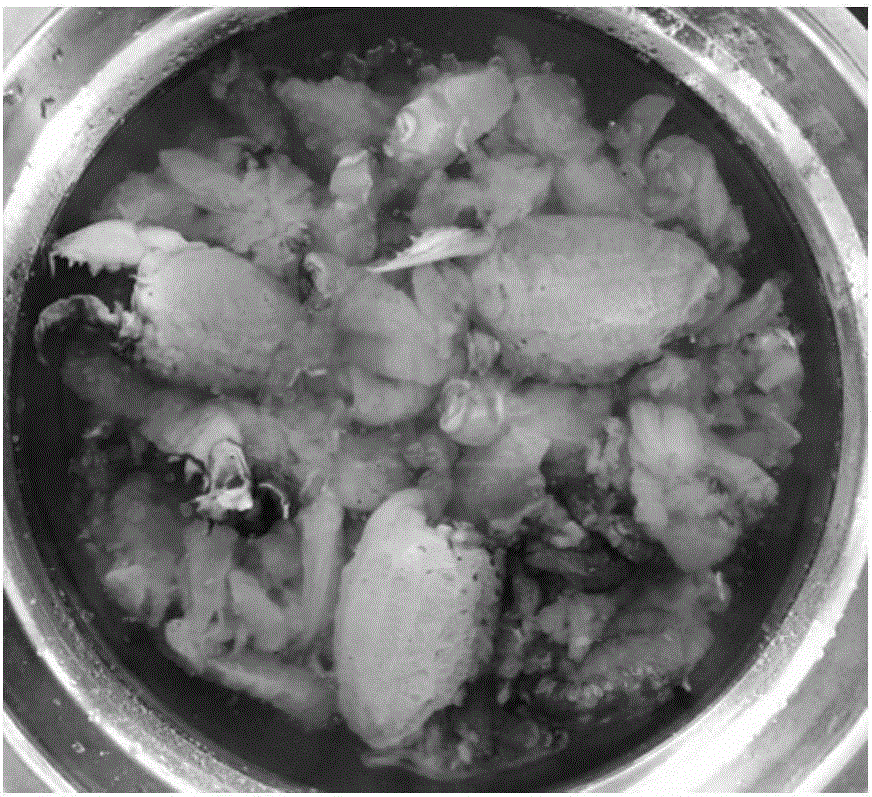

[0037] (1) Pre-treatment: Wash the mud and dirt attached to the crab body with clean water, remove the crab cover shell, remove the crab gills and belly button with a stainless steel knife, then clean the crab body with ice water, and use a special Stainless steel utensils for splitting and picking meat;

[0038] (2) soaking: put the crabmeat of step (1) into the seasoning liquid and soak;

[0039] (3) Cooking: steam the crab meat soaked in step (2), boil the seasoning liquid with low heat, and boil the seasoning liquid;

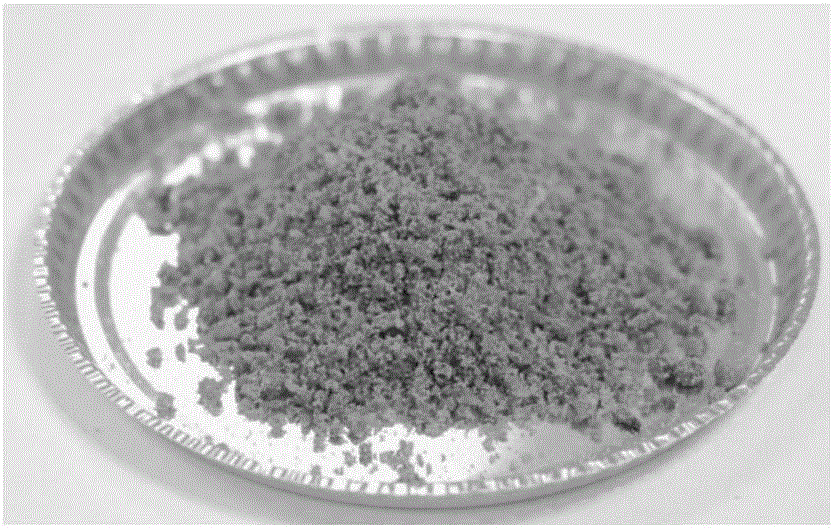

[0040] (4) One-time baking: Put the crab meat obtained in step (3) into a preheated oven, bake until 50% dry, and set aside;

[0041] (5) shred: put the crabmeat that step (4) obtains into shredder and shred, for subsequent use;

[0042] (6) Stir fry: put the crab meat obtained in...

Embodiment 2

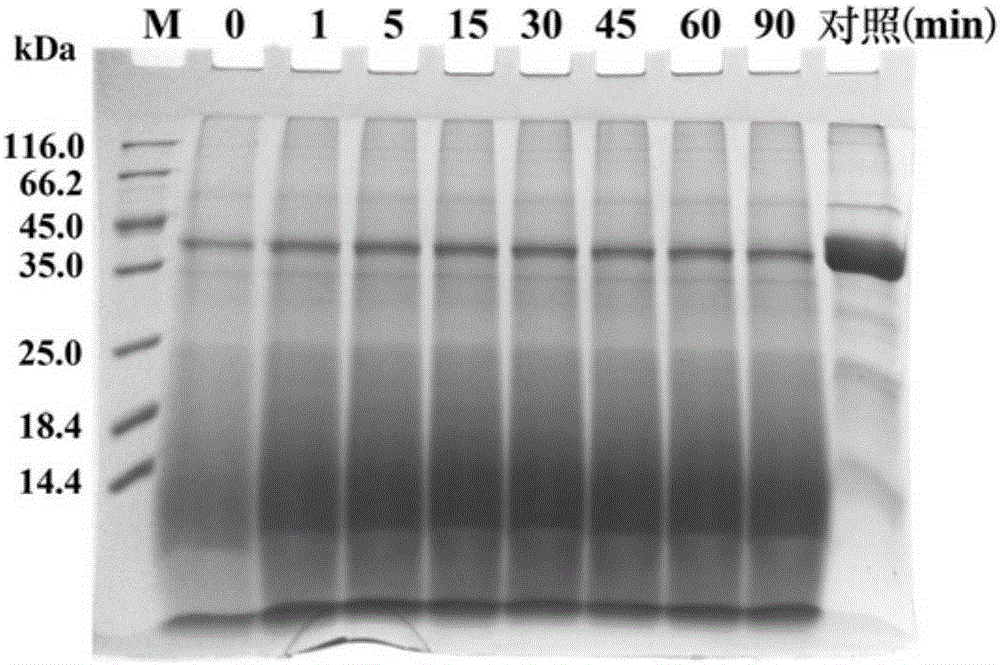

[0045] Example 2: In Vitro Simulated Gastric Juice Digestion of Hypoallergenic Crab Floss Crude Protein

[0046] (1) Preparation of crude protein from crabmeat floss. Take the finished crabmeat floss and put it in 4 times volume (v / w) of ice-cold 0.5mol / LNaCl Tris-HCl buffer solution (20mmol / L, pH8.0), mash the tissue, repeat 5 times, centrifuge (12000g, 20min , 4°C), the supernatant is crude protein from crab floss.

[0047] (2) In vitro simulated gastric juice digestion of crude protein. Referring to the method of simulating gastric juice digestion in vitro in the United States Pharmacopoeia, pig pepsin was used for the simulated gastric juice digestion experiment, and the pepsin enzyme activity used was 109U / mg protein. Use 1 mL of simulated gastric juice (containing 50 mmol / L NaCl, pH 1.2) reaction system, the ratio of pepsin to crude crab floss extract is 1:4000 (w / w), and the final concentration of the crude extract in the reaction solution is 3 mg / mL. Shake the react...

Embodiment 3

[0050] Example 3: Inhibition ELISA Analysis of Crab Allergen (Arginine Kinase) Digestion Products

[0051] (1) Coated and closed. The crab floss crude extract protein diluted in the coating solution was coated on a 96-well ELISA plate with a volume of 100 μL / well (the amount of coated protein per well was 200 ng), sealed and incubated at 4°C for 16 hours. Then pour off the liquid in the well, pat dry, wash 300 μL / well with TBST, and repeat 5 times. Pat the liquid in the plate dry, add 5% skimmed milk to block, 300 μL / well, and incubate at 37°C for 1.5h.

[0052] (2) Pre-incubation reaction between serum and inhibitor. Add serum from patients with crab allergy (diluted 1:2 with 1% skimmed milk, 30 μL / well) on another uncoated microplate, and mix with equal amount of inhibitor (diluted 1:10 with 1% skimmed milk) The digestion products of crabmeat crude protein were digested by pepsin, trypsin, and chymotrypsin for 1h, 4h, and 4h respectively; the undigested crabmeat floss cru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com