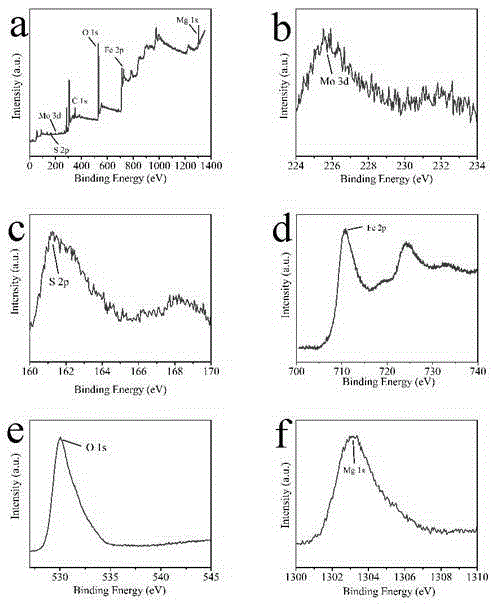

Synthesis method and application of magnesium ferrite/molybdenum sulfide heterostructure nanowires

A synthesis method and technology of magnesium ferrite, applied in chemical instruments and methods, physical/chemical process catalysts, hydrogen production, etc., to achieve the effects of improving utilization rate, good reproducibility, reducing energy consumption and reaction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

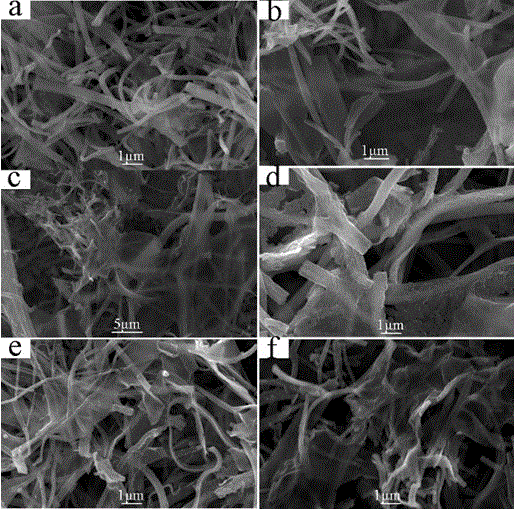

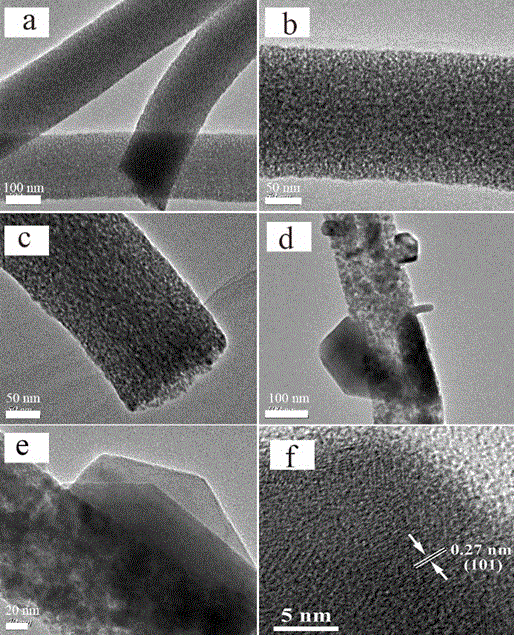

[0028] Embodiment 1 The mass ratio of molybdenum sulfide and magnesium ferrite is 0.02

[0029] (1) Weigh 15mmol of ferric nitrate and 5mmol of magnesium nitrate and place in a 50mL test tube, then add 2.5mL of twice distilled water and 7.5mL of absolute ethanol and stir well, then add 1.3g of PVP (K90), and finally mix it well to get clarification solution, namely the electrospinning precursor.

[0030] (2) Draw 5mL of the precursor solution in a glass syringe, and then conduct electrospinning at 25KV through an electrospinning device, then collect the product, and calcinate it through a muffle furnace at 500°C to obtain magnesium ferrite; the electrospinning experiment is in It is carried out at 25 degrees Celsius and 55 degrees humidity, and the heating conditions during calcination are from 1°C / min to 400°C, and from 5°C / min to 500°C.

[0031] (3) Weigh 2mg of ammonium molybdate and 19mg of thiourea and mix evenly, then place them on both ends of the porcelain boat with...

Embodiment 2

[0032] Embodiment 2 The mass ratio of molybdenum sulfide and magnesium ferrite is 0.05

[0033] (1) Weigh 15mmol of ferric nitrate and 5mmol of magnesium nitrate and place in a 50mL test tube, then add 2.5mL of twice distilled water and 7.5mL of absolute ethanol and stir well, then add 1.3g of PVP (K90), and finally mix it well to get clarification solution, namely the electrospinning precursor.

[0034](2) Draw 5mL of the precursor solution in a glass syringe, and then conduct electrospinning at 25KV through an electrospinning device, then collect the product, and calcinate it through a muffle furnace at 500°C to obtain magnesium ferrite. The electrospinning experiment is in It is carried out at 25 degrees Celsius and 55 degrees humidity, and the heating conditions during calcination are from 1°C / min to 400°C, and from 5°C / min to 500°C.

[0035] (3) Weigh 5mg of ammonium molybdate and 47.5mg of thiourea and mix them evenly, then place them on both ends of the porcelain boa...

Embodiment 3

[0036] Embodiment 3 The mass ratio of molybdenum sulfide and magnesium ferrite is 0.1

[0037] (1) Weigh 15mmol of ferric nitrate and 5mmol of magnesium nitrate and place in a 50mL test tube, then add 2.5mL of twice distilled water and 7.5mL of absolute ethanol and stir well, then add 1.3g of PVP (K90), and finally mix it well to get clarification solution, namely the electrospinning precursor.

[0038] (2) Draw 5mL of the precursor solution in a glass syringe, and then conduct electrospinning at 25KV through an electrospinning device, then collect the product, and calcinate it through a muffle furnace at 500°C to obtain magnesium ferrite. The electrospinning experiment is in It is carried out at 25 degrees Celsius and 55 degrees humidity, and the heating conditions during calcination are from 1°C / min to 400°C, and from 5°C / min to 500°C.

[0039] (3) Weigh 10mg of ammonium molybdate and 95mg of thiourea and mix them evenly, then place them on both ends of the porcelain boat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com