Preparation method and application of Au/PILs (Polymeric Ionic Liquids)/PPyNTs (Polypyrrole Natotubes) composite material

A composite material and polymerized ionic liquid technology, which is applied in the field of preparation of gold nanoparticle/polymeric ionic liquid/polypyrrole nanotube composite material, can solve the problems of technicians requiring relatively high operation steps, expensive equipment and complicated equipment, etc. Effects of electron transport rate, state modulation convenience, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1A

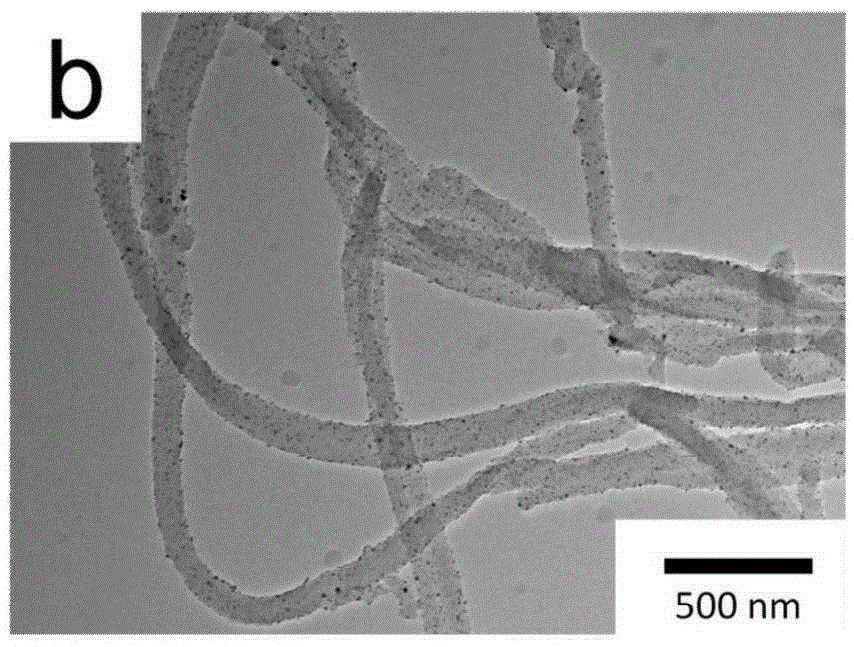

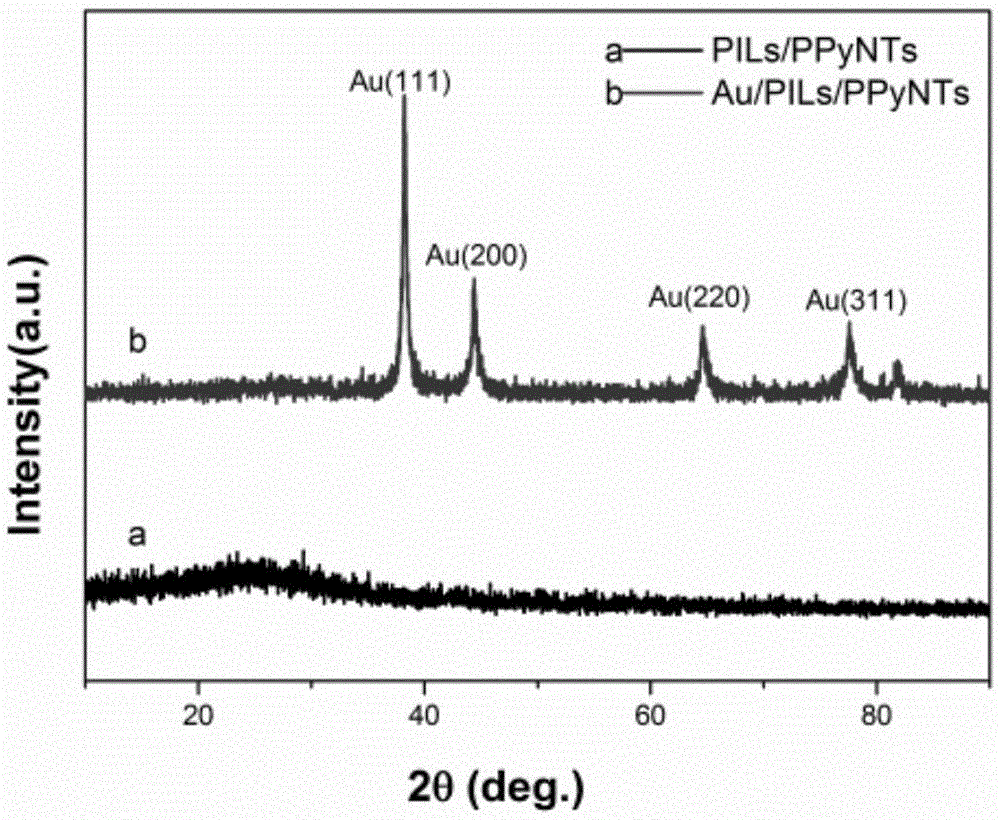

[0046] The preparation of embodiment 1Au / PILs / PPyNTs composite material

[0047] (1) Preparation method

[0048] Synthetic route such as Figure 8 shown.

[0049] 1. Synthesis of ionic liquid modified polypyrrole nanotubes (ILs / PPyNTs)

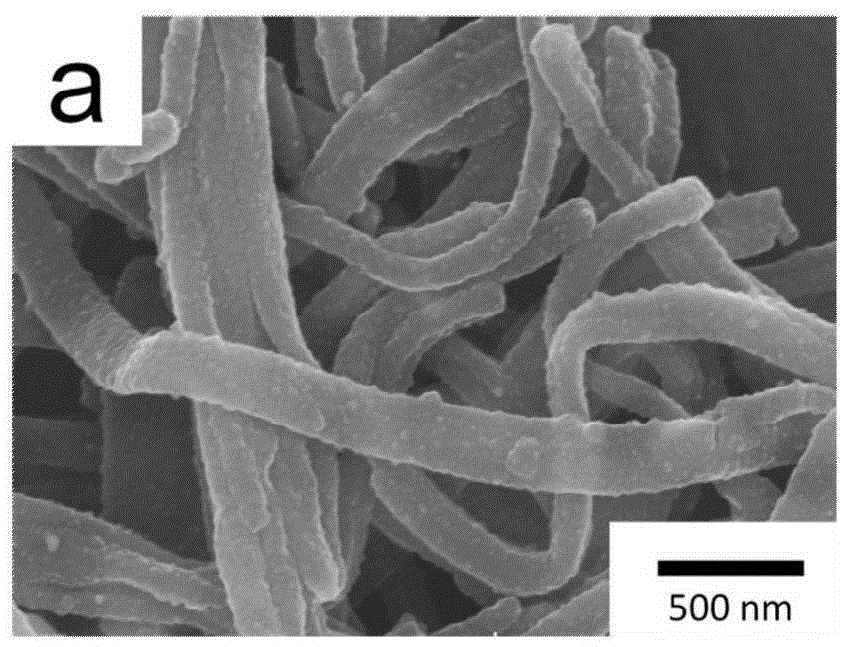

[0050] 1.1) Synthesis of PPyNTs

[0051] Polypyrrole nanotubes were synthesized by self-degradation template method. The methyl orange (MO) that takes 0.05g is added in the conical flask that contains 30mL water, after fully dissolving, then add 0.249g iron trichloride, after stirring for 5 minutes, add 0.113g pyrrole monomer again, in After stirring at room temperature for 24 hours, wash with distilled water and ethanol until neutral, and dry in vacuum at 50°C for 24 hours to obtain PPyNTs.

[0052] 1.2) PPyNTs-(CH 2 ) 4 -Synthesis of Br

[0053] Weigh 0.031g of PPyNTs and 0.055g of potassium hydroxide into a single-necked round-bottomed flask, then add 0.156g of 1,4-dibromobutane, disperse in 25mL of DMF, ultrasonically disperse for ...

Embodiment 2A

[0066] Application of Example 2 Au / PILs / PPyNTs composite material to the electrocatalytic performance of epinephrine (EP)

[0067] (1) The method is as follows:

[0068] 1) Take 1 mg of dried Au / PILs / PPyNTs nanocomposite, add it to 1 mL of ethanol, and ultrasonically disperse for 20 minutes to obtain a uniformly dispersed black suspension.

[0069] 2) Al for glassy carbon electrode 2 o 3 After polishing, they were ultrasonically cleaned in water and ethanol respectively, and after drying in the air, pipette 3 μL of the above dispersed black suspension of Au / PILs / PPyNTs onto a clean glassy carbon electrode ( GCE) surface, placed in the air, you can get a glassy carbon electrode (Au / PILs / PPyNTs / GCE) modified with Au / PILs / PPyNTs, dry it for later use.

[0070] At the same time, PILs / PPyNTs nanotube-modified glassy carbon electrodes (PILs / PPyNTs / GCE) were prepared by the same method for comparison.

[0071] 3) Put Au / PILs / PPyNTs / GCE in a phosphate buffer solution containing ep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com