Method for preparing baricitinib

A technology of baricitinib and tert-butyl formate, which is applied in the direction of organic chemistry, can solve the problems of complex operation, low total reaction yield, troublesome removal, etc., and achieve high reaction yield, simple process, and easy-to-obtain raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

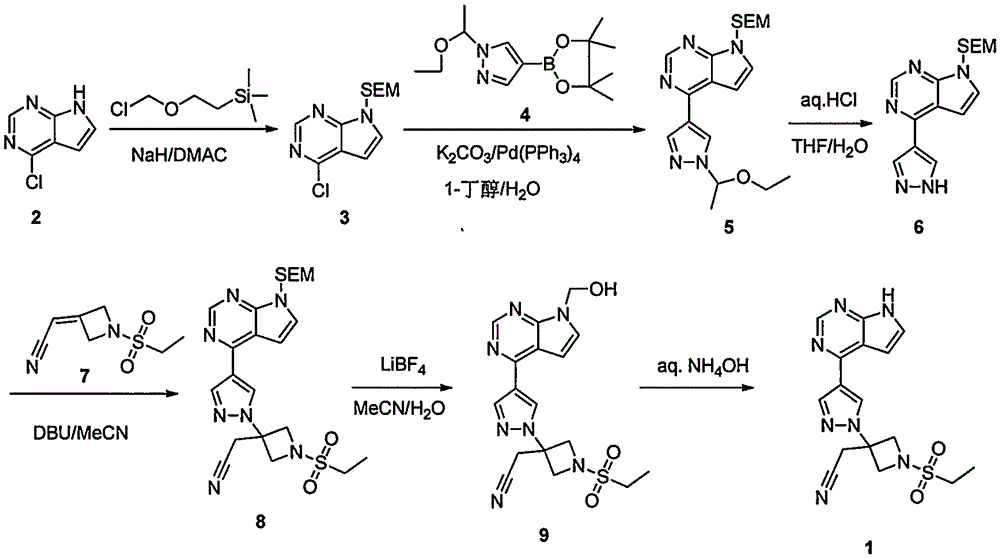

Method used

Image

Examples

Embodiment 1

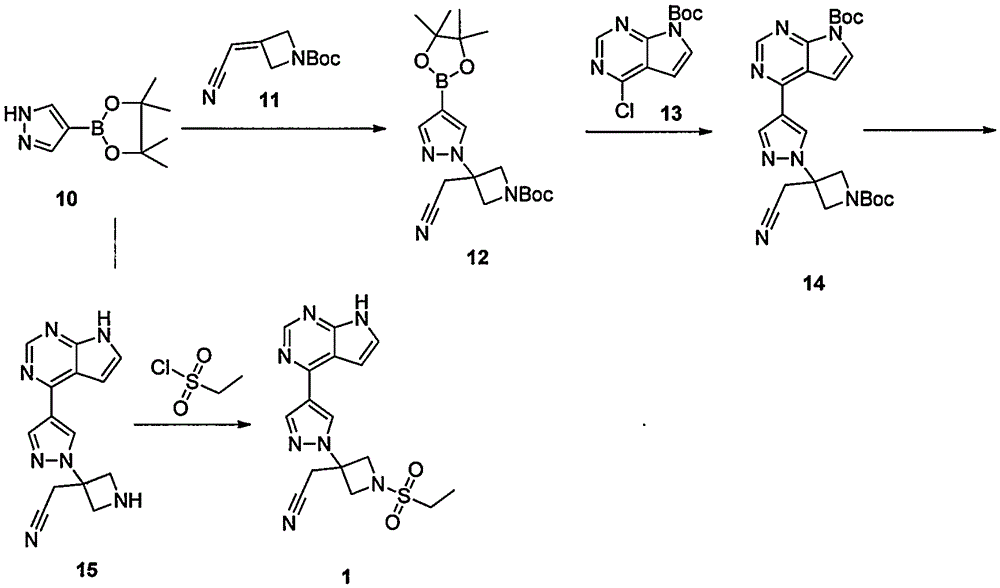

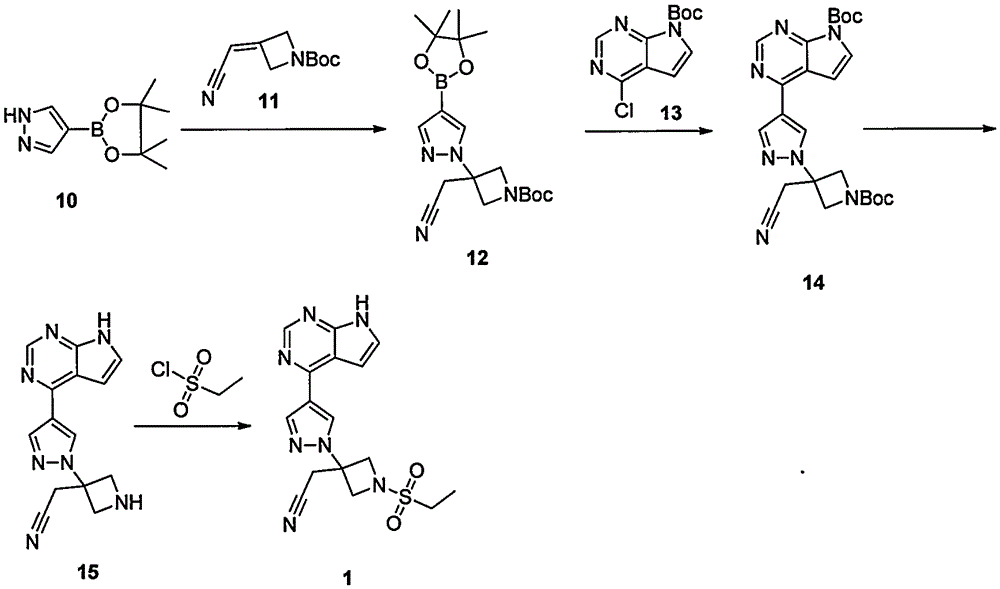

[0028] Preparation of tert-butyl 3-(cyanomethylene)-3-(4-pyrazoleboronic acid pinacol ester)-azetidine-1-carboxylate (12)

[0029] In a 2L reaction flask, add acetonitrile (800mL), 4-pyrazoleboronic acid pinacol ester (10, 77.6g, 0.4mol), 3-(cyanomethylene)azetidine-1-carboxylic acid tert- Butyl ester (11, 77.6 g, 0.4 mol) and urea (2.4 g, 0.04 mol). The reaction was stirred at room temperature for 12 h, concentrated to dryness under reduced pressure, ethyl acetate (500 mL) and water (300 mL) were added to the residue, stirred and separated, and the organic layer was washed with saturated brine (300 mL) and separated. The organic layer was concentrated to dryness under reduced pressure, absolute ethanol (200 mL) was added to the residue, stirred for 30 min, filtered, the filter cake was washed with absolute ethanol (50 mL), and vacuum-dried (50°C) for 5 h to obtain 3-(cyano Methylene)-3-(4-pyrazoleboronic acid pinacol ester)-azetidine-1-carboxylic acid tert-butyl ester (12, 1...

Embodiment 2

[0031] Preparation of tert-butyl 3-(cyanomethylene)-3-(4-pyrazoleboronic acid pinacol ester)-azetidine-1-carboxylate (12)

[0032] In a 2L reaction flask, add acetonitrile (800mL), 4-pyrazoleboronic acid pinacol ester (10, 77.6g, 0.4mol), 3-(cyanomethylene)azetidine-1-carboxylic acid tert- Butyl ester (11, 85.4 g, 0.44 mol) and thiourea (6.1 g, 0.08 mol). The reaction was stirred at room temperature for 10 h, concentrated to dryness under reduced pressure, ethyl acetate (500 mL) and water (300 mL) were added to the residue, stirred and separated, and the organic layer was washed with saturated brine (300 mL) and separated. The organic layer was concentrated to dryness under reduced pressure, absolute ethanol (250 mL) was added to the residue, stirred for 30 min, filtered, the filter cake was washed with absolute ethanol (50 mL), dried in vacuum (50°C) for 5 h, and 3-(cyano Methylene)-3-(4-pyrazoleboronic acid pinacol ester)-azetidine-1-carboxylic acid tert-butyl ester (12, 15...

Embodiment 3

[0034] Preparation of tert-butyl 3-(cyanomethylene)-3-(4-pyrazoleboronic acid pinacol ester)-azetidine-1-carboxylate (12)

[0035] In a 2L reaction flask, add acetonitrile (800mL), 4-pyrazoleboronic acid pinacol ester (10, 77.6g, 0.4mol), 3-(cyanomethylene)azetidine-1-carboxylic acid tert- Butyl ester (11, 93.1 g, 0.48 mol) and urea (7.2 g, 0.12 mol). The reaction was stirred at room temperature for 12 h, concentrated to dryness under reduced pressure, ethyl acetate (500 mL) and water (300 mL) were added to the residue, stirred and separated, and the organic layer was washed with saturated brine (300 mL) and separated. The organic layer was concentrated to dryness under reduced pressure, absolute ethanol (300 mL) was added to the residue, stirred for 30 min, filtered, the filter cake was washed with absolute ethanol (50 mL), and vacuum-dried (50°C) for 5 h to obtain 3-(cyano Methylene)-3-(4-pyrazoleboronic acid pinacol ester)-azetidine-1-carboxylic acid tert-butyl ester (12, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com