A method for preparing 3-succinylpyridine through biotransformation

A succinylpyridine and biotransformation technology, applied in the field of preparation of 3-succinylpyridine, can solve the problems of insufficient research and reports on 3-succinylpyridine, achieve low cost, realize conversion, and simple catalytic reaction system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

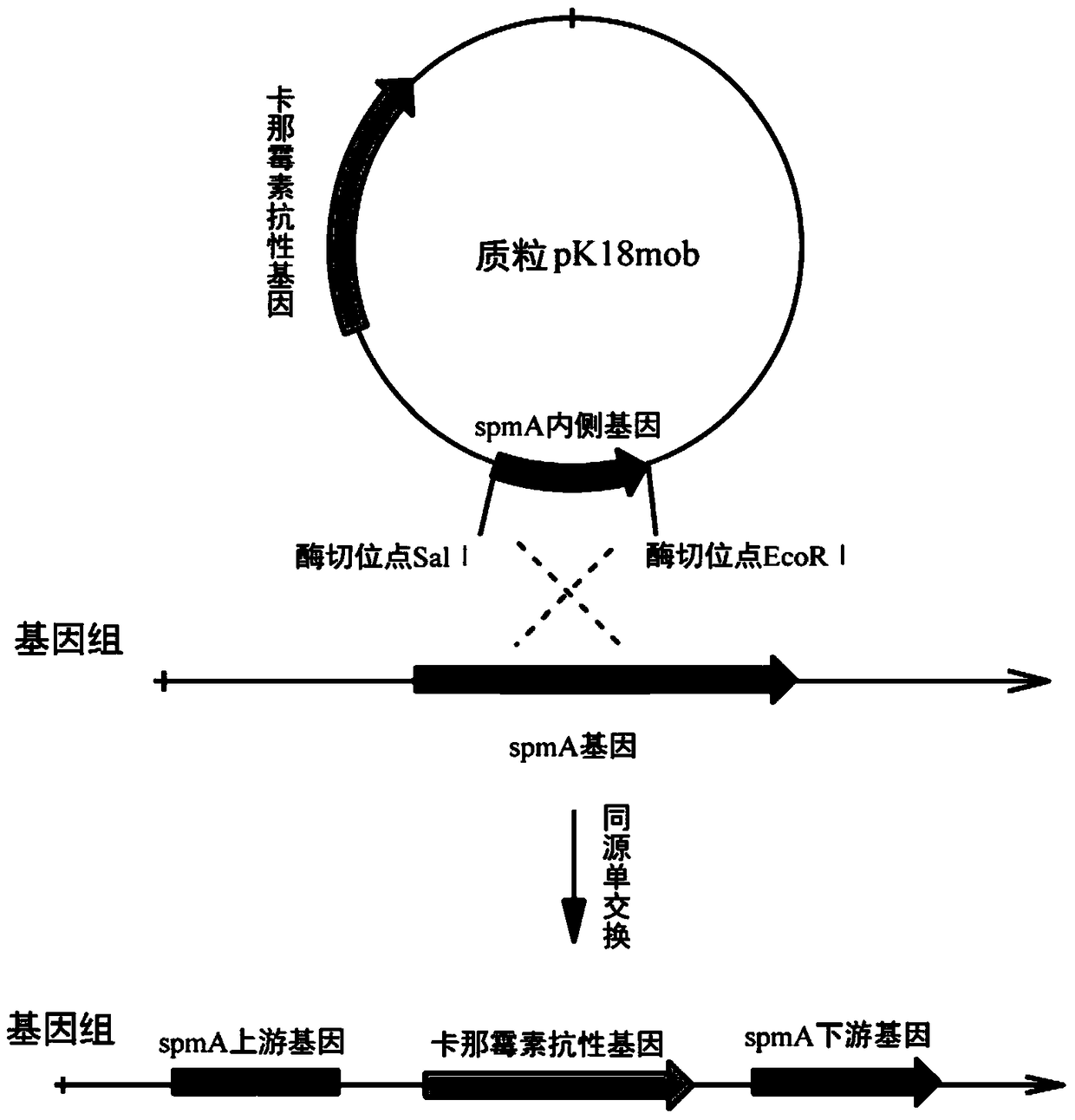

[0047] Embodiment 1: the construction of Pseudomonas putida (Pseudomonas putida) genetically engineered bacteria, see image 3

[0048] Based on the principles of genetic engineering, in combination with relevant molecular biology methods, the construction of Pseudomonas putida genetically engineered bacteria is completed, and the specific implementation steps are as follows:

[0049] (1) Primer design: the upstream primer is spm-F:CCAC GTC GAC CAAGTTAACTGGTTATGCGAC, the enzyme cutting site is Sal Ⅰ; the downstream primer is spm-R:CCAC GAATTC AGTCCTTGGCCGAAACTTTGC, the enzyme cutting site is EcoR Ⅰ.

[0050] (2) DNA fragment amplification: Using the genome of Pseudomonas putida CCTCC M 205038 as a template, using the upstream and downstream primers described in (1), amplify by PCR technique to obtain multiple copies of the target DNA fragment.

[0051] (3) Plasmid construction and transformation: The PCR product in (2) and the shuttle plasmid pK18mob were digested with res...

Embodiment 2

[0053] Embodiment 2: Extract nicotine from waste tobacco leaves

[0054] Under laboratory conditions, the method of secondary extraction is used to extract nicotine from waste tobacco leaves. The specific implementation steps are as follows:

[0055] (1) The waste and inferior tobacco leaves are provided by Henan China Tobacco Company. The waste and inferior tobacco leaves are first dried and crushed into powder. Weigh 50g of tobacco leaf powder and add it to 600mL of distilled water. After stirring evenly, adjust the pH to 11, then continuously stirred on the stirrer for 2 hours, and stood overnight.

[0056] (2) Remove the filter residue by filtration to obtain about 500 mL of filtrate containing nicotine, add 100 mL of chloroform to it for extraction, the extraction temperature is 37 ° C, adjust the pH to 11, stir and extract for 3 hours; use a separatory funnel to remove the water phase to obtain nicotine-containing chloroform phase.

[0057] (3) Utilize 20mL dilute sulf...

Embodiment 3

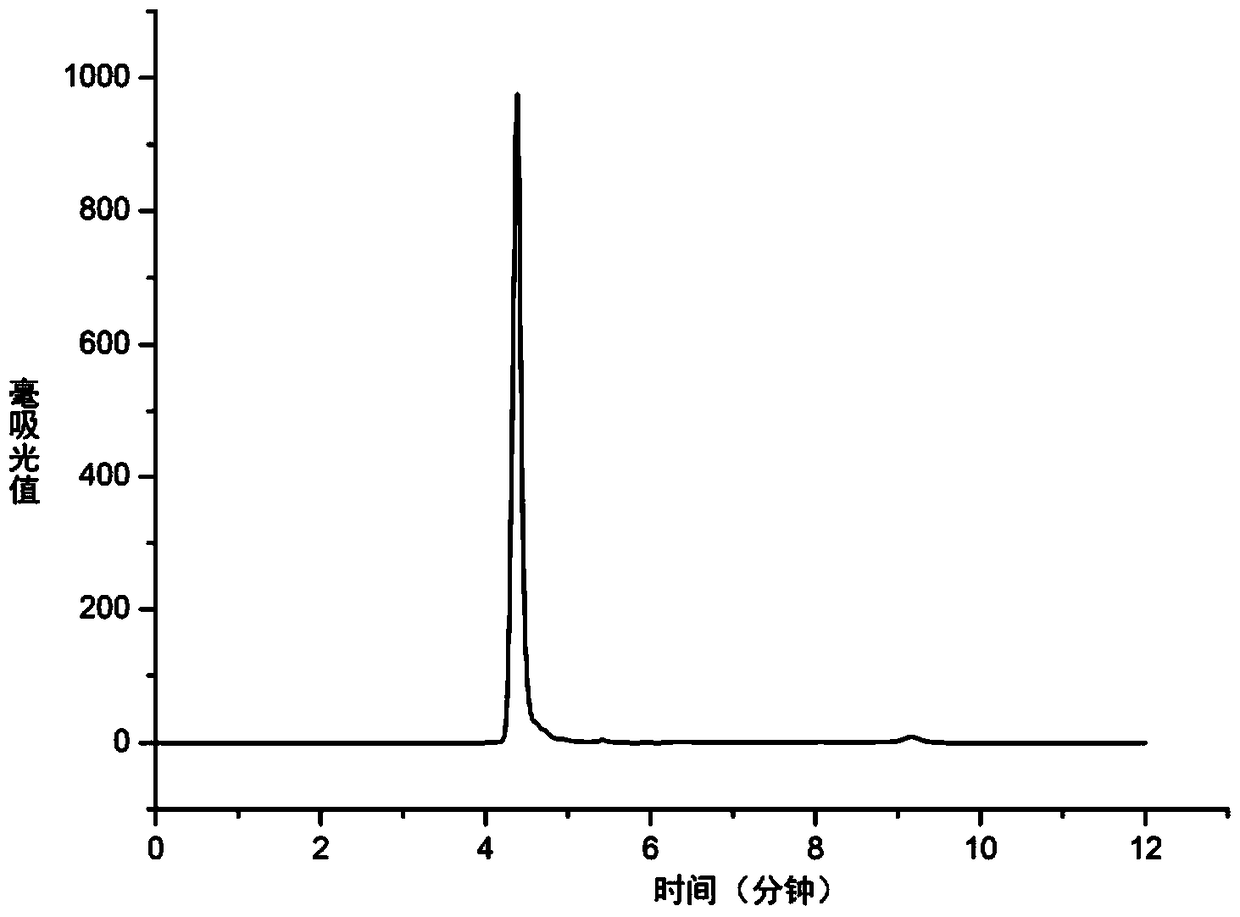

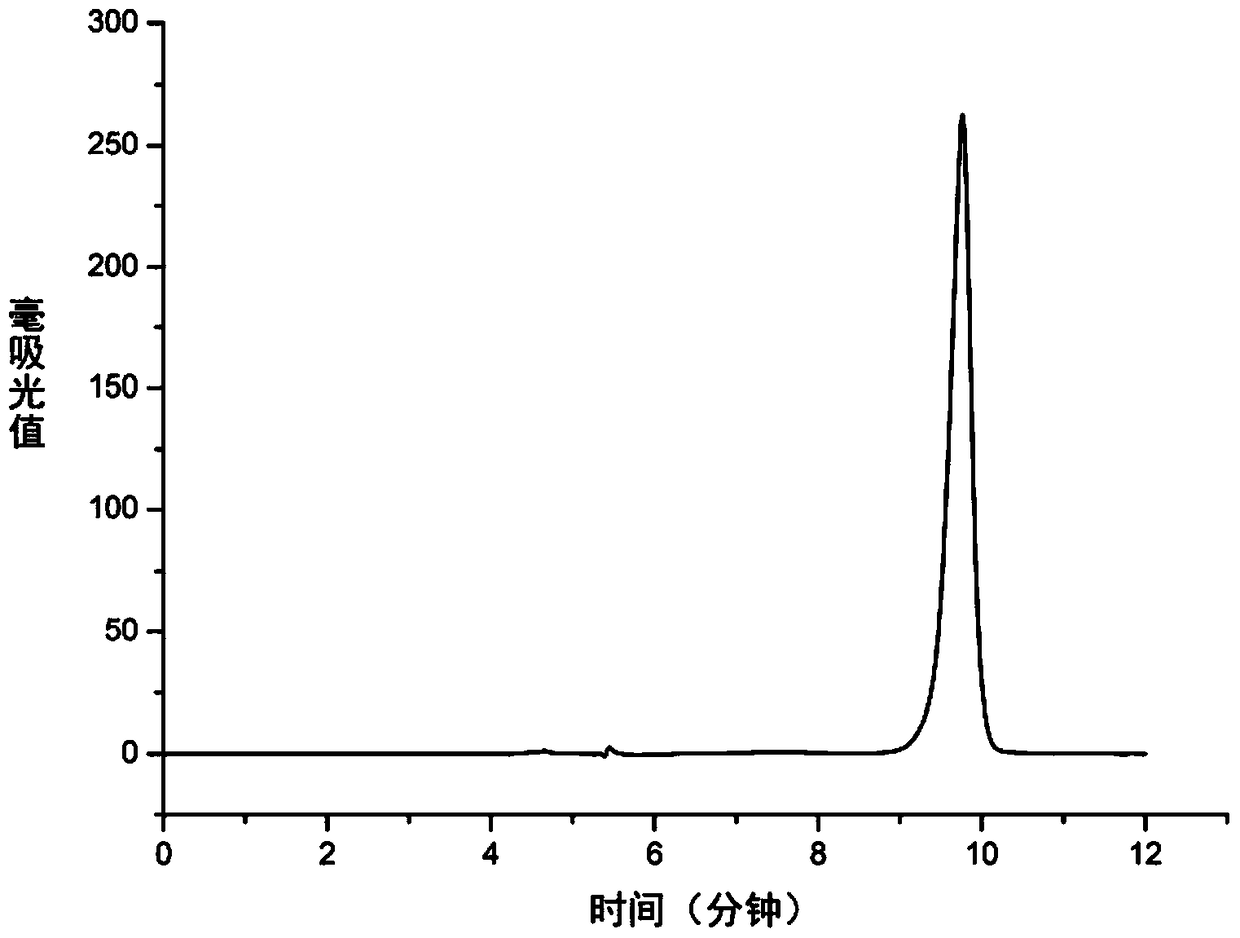

[0059] Example 3: Nicotine is biotransformed to 3-succinylpyridine

[0060] (1) Biocatalyst: the microbial strain used for biotransformation is Pseudomonas putida (Pseudomonasputida) genetically engineered bacteria;

[0061] (2) Slant culture: inoculate the bacterial strain in step (1) to solid slant LB culture medium, cultivate 15 hours at 30 ℃; Described solid slant LB medium group contains 1.5% agarose, 1g / L nicotine and 50mg / L L Kanamycin;

[0062] (3) Seed culture: the thalline with good growth on the slant in step (2) is transferred to the LB liquid medium in a sterile environment, and the LB liquid medium contains kanamycin 50mg / L and 1g / L nicotine, cultivated at 30°C for 12 hours to obtain seed liquid;

[0063] (4) Scale-up cultivation: transfer the seed solution in step (3) to 1L LB liquid medium according to 2% inoculum size, which contains 50mg / L kanamycin and 1g / L nicotine , cultured at 200 rpm at 30°C for 12 hours to mid-logarithmic growth;

[0064] (5) Colle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com