Method for preparing hetero-atom doped porous carbon material through carbonation of biomass under assistance of molten salt

A technology of porous carbon materials and molten salts, which is applied in the field of preparation of porous carbon materials, can solve the problems of cumbersome steps in the template method, corrosion of production equipment, environmental pollution, etc., and achieve the effects of low cost, easy operation, and high purity of reactants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Preparation of N-doped porous carbon materials

[0026] Weigh 1g of tofu powder (obtained by freeze-drying and grinding of tofu purchased in the market), and 5g of molten salt of LiCl / KCl (the mass ratio of LiCl and KCl is 59 / 41) and 0.1g of KNO 3 After mixing evenly, put it into a tube furnace, under Ar atmosphere, at 5°C min -1 The heating rate was increased to 750°C, and the temperature was kept constant for 60 minutes. After cooling, it was washed with distilled water to remove the molten salt, and it was centrifuged and dried for later use.

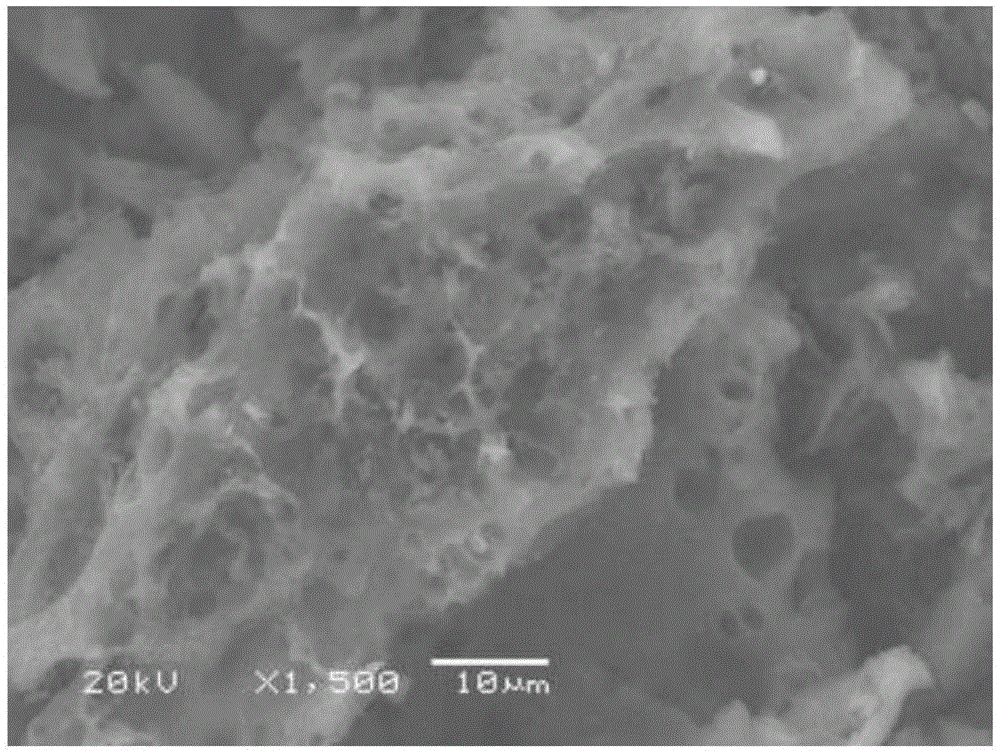

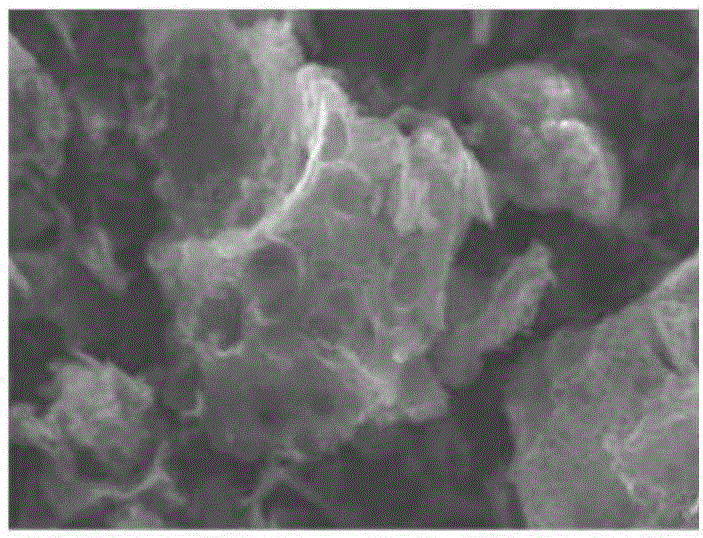

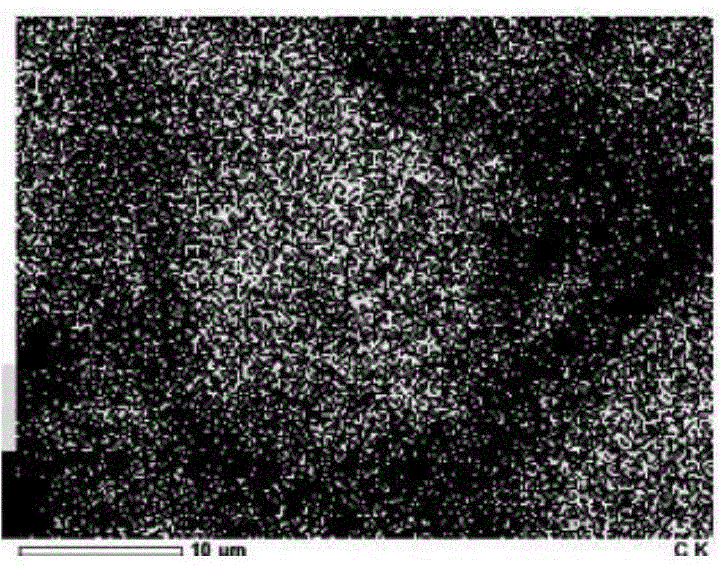

[0027] The physical and chemical properties of the prepared porous carbon material were characterized by scanning electron microscopy, nitrogen adsorption and desorption analysis, and elemental analyzer. The results are shown in figure 1 , Figure 2 and image 3 , the supercapacitor test was carried out on the prepared porous carbon material, the results are shown in Figure 4 .

[0028] figure 1 It shows that the prepared...

Embodiment 2

[0030] Preparation of S-doped porous carbon materials

[0031] Weigh 1g of biomass powder (obtained by grinding sawdust after drying at high temperature), mix it with 5g of LiCl / KCl salt (the mass ratio of LiCl and KCl is 59 / 41) and 0.1g of NaS, and put it into the tube In the furnace, under Ar atmosphere, at 5°C min -1 The heating rate was increased to 750°C, and the temperature was kept constant for 60 minutes. After cooling, it was washed with distilled water to remove the molten salt, and it was centrifuged and dried for later use.

[0032] The specific surface area of the S-doped carbon material prepared by nitrogen adsorption and desorption analysis is 1310m 2 g -1 , Elemental analysis results are carbon 90.4%, oxygen 6.5%, sulfur 3.1%. Supercapacitor performance test shows that 1A g -1 Under the discharge current density, the specific capacity is 285F·g -1 , 50A·g -1 When the capacitance is still maintained at 120F·g -1 .

Embodiment 3

[0034] Preparation of N and S doped porous carbon materials

[0035] Weigh 1g of biomass powder (obtained by drying, dehydrating and grinding green seaweed), mix it with 5g of LiCl / KCl salt (the mass ratio of LiCl and KCl is 59 / 41) and 0.1g of thiourea, and put it into the tube In a type furnace, under Ar atmosphere, at 5°C·min -1The heating rate was increased to 750°C, and the temperature was kept constant for 60 minutes. After cooling, it was washed with distilled water to remove the molten salt, and it was centrifuged and dried for later use.

[0036] The specific surface area of the N and S co-doped carbon material prepared by nitrogen adsorption and desorption analysis is 1800m 2 g -1 , The elemental analysis results are 88.6% carbon, 5.5% oxygen, 3.5% nitrogen, and 2.4% sulfur. Supercapacitor performance test shows that 1A g -1 Under the discharge current density, the specific capacity is 350F·g -1 , 50A·g -1 When the capacitance is still maintained at 180F·g -1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com