A kind of method for preparing modified graphene polyvinyl alcohol composite film

A technology of polyvinyl alcohol and composite film, which is applied in the field of preparing modified graphene-polyvinyl alcohol composite film, which can solve the limitations of graphene/polyvinyl alcohol composite material research and application range, poor hydrophilicity and lipophilicity, Weak interaction and other problems, to achieve the effect of good chemical stability and biocompatibility, low price, and enhanced interface binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

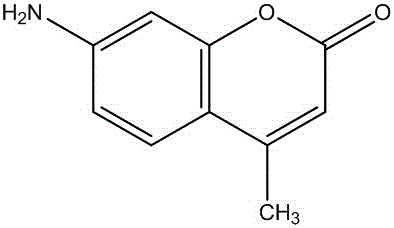

[0029] 1) Preparation of modified graphene: first disperse graphene oxide in deionized water, and stir at room temperature for 0.1-10 h with ultrasonic vibration to obtain a graphene oxide-water dispersion with a concentration of 0.01-1.0 mg / mL; then Add 7-amino-4-methylcoumarin to the graphene oxide-water dispersion, stir at 20-50°C for 0.1-5h; then add alkaline solution, stir for 0.1-5h, and adjust the pH to 9-10; then add a chemical reducing agent, react at 60-95°C for 12-96h to obtain a modified mixed solution; suction filter the modified mixed solution to obtain a solid substance, and then wash the described mixed solution with ethanol and deionized water in sequence Solid matter to neutral; placed in the atmosphere or in a vacuum environment, dried at 40-70°C to constant weight to obtain modified graphene.

[0030] The operation of this step is to prepare modified graphene by adding modifier and chemically reducing graphene oxide. In described graphene oxide, 7-amino-4-...

Embodiment 1

[0040] Adopt the following method to prepare modified graphene-polyvinyl alcohol composite film:

[0041] 1) Preparation of modified graphene: first disperse graphene oxide in deionized water, and ultrasonically shake and stir at room temperature for 2 hours to obtain a graphene oxide-water dispersion with a concentration of 0.5 mg / mL;

[0042]Then add 7-amino-4-methylcoumarin to the graphene oxide-water dispersion, stir at 40°C for 1h; then add an aqueous sodium hydroxide solution with a concentration of 1.0 mol / L, stir for 1h, and Adjust the pH value to 9-10; then add the chemical reducing agent glucose, and react at 90°C for 24 hours to obtain the modified mixed solution;

[0043] Suction filter the modified mixed solution to obtain a solid substance, and then wash the solid substance with ethanol and deionized water to neutrality; place it in an atmospheric environment, and dry it to a constant weight at 60°C to obtain the modified graphene ;

[0044] The mass ratio of t...

Embodiment 2

[0049] Adopt the following method to prepare modified graphene-polyvinyl alcohol composite film:

[0050] 1) Preparation of modified graphene: first disperse graphene oxide in deionized water, and ultrasonically shake and stir at room temperature for 3 hours to obtain a graphene oxide-water dispersion with a concentration of 0.1 mg / mL;

[0051] Then add 7-amino-4-methylcoumarin to the graphene oxide-water dispersion, stir at 25°C for 2h; then add an aqueous sodium hydroxide solution with a concentration of 2.0 mol / L, stir for 0.5h, And adjust the pH value to 9-10; then add the chemical reducing agent vitamin C, and react at 95°C for 18 hours to obtain the modified mixed solution;

[0052] Suction filter the modified mixed solution to obtain a solid substance, and then wash the solid substance with ethanol and deionized water to neutrality; place it in an atmospheric environment, and dry it to a constant weight at 50°C to obtain the modified graphene ;

[0053] The mass ratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com