Surface modifying method of orthopedic implanted medical instrument

A surface modification and device technology, which is applied in the fields of pharmaceutical formulation, dentistry, medical science, etc., can solve the problems of curative effect discount, lack of targeting mechanism, etc., and achieve the effect of preventing loosening and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

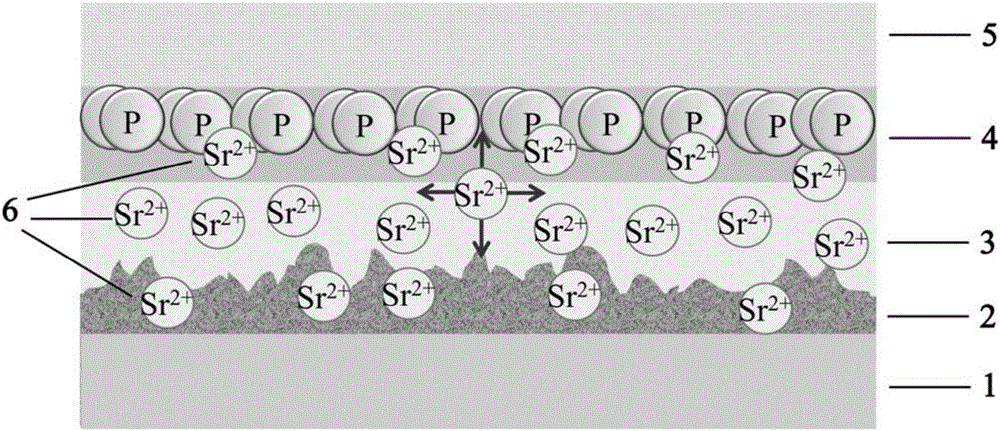

[0042] Example 1. Preparation of "Sr-BPs" film layer by "micro-arc oxidation-simulated body fluid method"

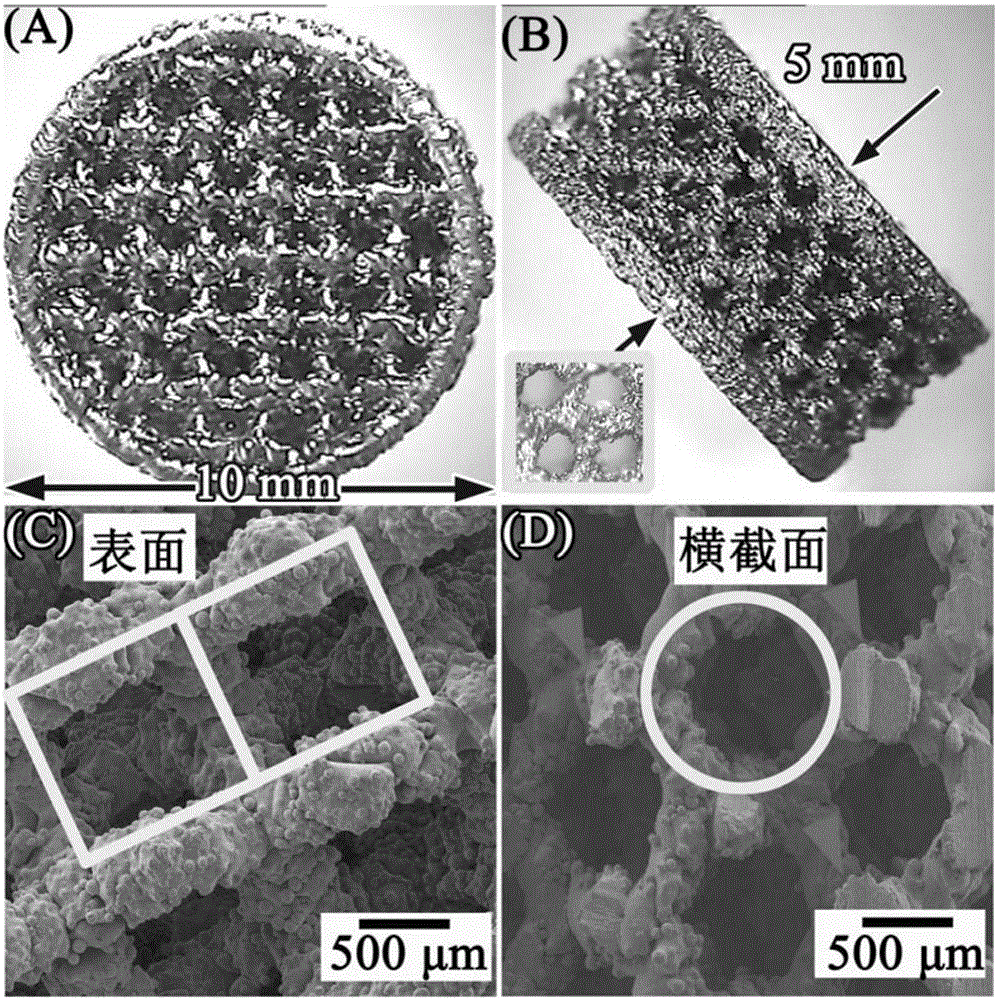

[0043] The Ti-6Al-4V porous scaffold 3D printed by electron beam melting was used as the sample. It has been determined that its diameter is 10mm, its height is 5mm, its pillar and pore size are about 400μm and 682μm respectively, and its porosity is 73% ( figure 2 ). The above scaffolds were powder blown, acetone-ethanol-deionized water ultrasonically cleaned and dried at 60°C, and then placed at room temperature for subsequent processing. Under the scanning electron microscope, some incompletely melted titanium powder microspheres bonded to the surface can be observed.

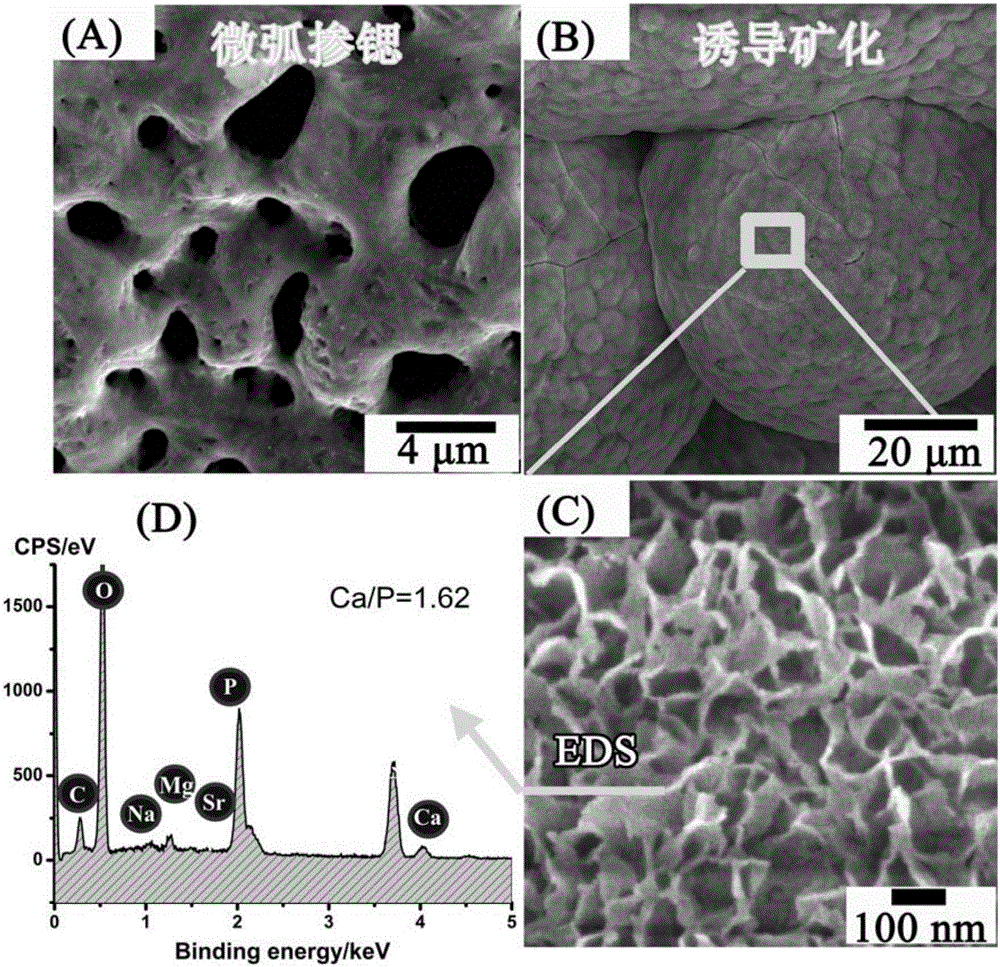

[0044] Firstly, a strontium-doped calcium phosphate surface (pretreatment film layer) with biological activity and microporous structure is prepared. Micro-arc oxidation was carried out in constant voltage mode by using JHMAO-6H pulsed DC power supply of Beijing Golden Arc Lvbao. The above bracket...

Embodiment 2

[0047] Example 2, "Sr-BPs" film layer prepared by "micro-arc oxidation-hydrothermal method"

[0048]The microporous structure on the surface of the stent after the above-mentioned micro-arc oxidation endows it with a large specific surface area and reactivity, which can be used as a template for a secondary reaction, and then induced by the hydrothermal reaction of a weak alkaline solution. With the micropores as the center, it can be used in A disordered nanorod-like structure is formed at its periphery. The "micropore-nanorod" composite hierarchical structure (intermediate layer) has a higher specific surface area and biological activity than a single microporous structure, and can directly utilize the PO of BPs without SBF induction. 4 3- and the Ca-rich surface of the nanorods 2+ The principle of electrostatic adsorption combined with BPs. The morphology of nanorods after adsorbing BPs is as follows: Figure 4 shown. The bright area in the figure is the C-rich element...

Embodiment 3

[0052] Example 3, "Sr-BPs" film layer prepared by "alkali heat-simulated body fluid method"

[0053] First, according to every 5-10mL alkaline solution / sample, use NaOH solution with a concentration gradient of 1M, 2.5M, 5M, 10M to carry out alkaline heat treatment at a temperature of 100-240°C, and the reaction time varies from 1-48h, so that the final Nanowire (nanofiber) film layers with different thicknesses and diameters were obtained on the surface of the titanium alloy. The obtained scaffold was washed with a large amount of deionized water to remove residual alkaline ions, and then dried at 60°C. Through this step, we can obtain nanowires with a diameter of 8-10 nm and a length of tens of microns to hundreds of microns ( Figure 5 ). In terms of composition, the nanowire "kaolin-like" layered structure has a large lattice activity and a super ion exchange capacity. Therefore most ions (Mg 2+ , Ca 2+ 、Sr 2+ , Zn 2+ 、Ag + 、Cu + etc.) can be compared with the Na ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com