Preparation and applications of molecular sieve gasoline desulfurizing agent loaded with functionalized ionic liquid

A technology of ionic liquid and molecular sieve, which is applied in the field of oil processing, can solve the problems of increased equipment investment and operating costs, lower octane number of fuel oil, and low hydrogenation rate constant, so as to improve catalytic oxidation efficiency, facilitate regeneration, Improve the effect of dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

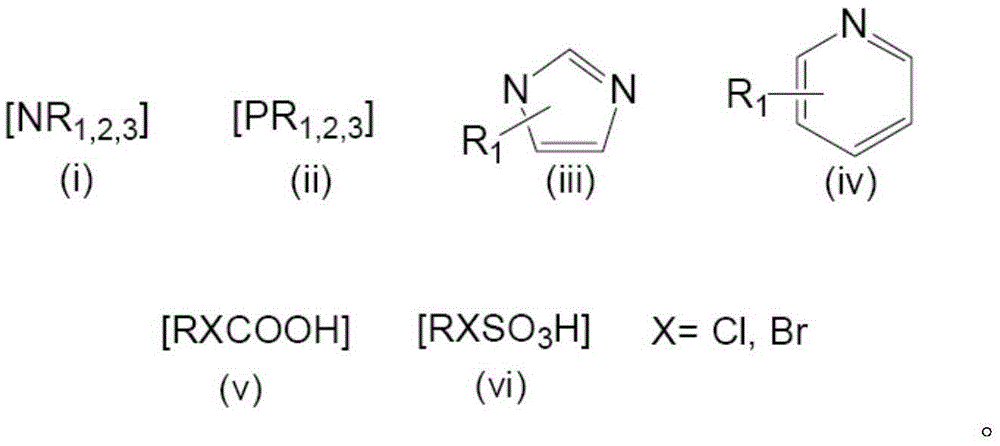

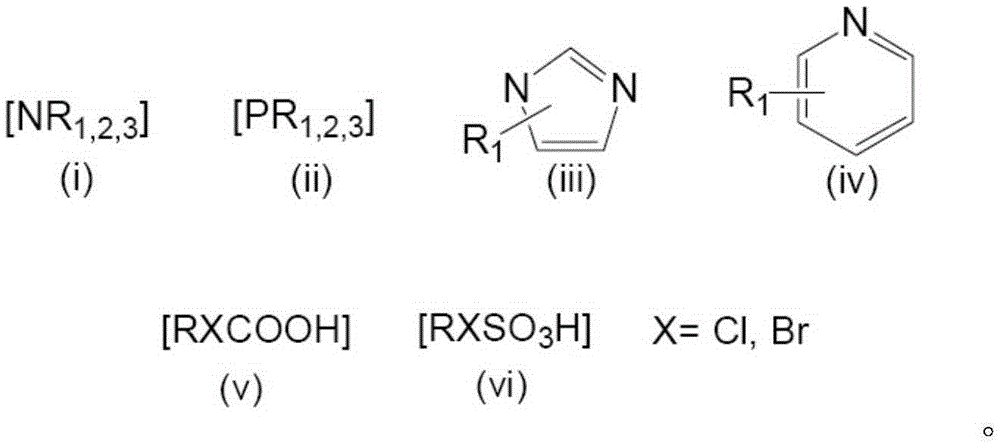

Method used

Image

Examples

Embodiment 1

[0035] A preparation method of a molecular sieve gasoline desulfurizer loaded with functionalized ionic liquid, comprising the following steps:

[0036] (1) Add 0.10mol of N-methylimidazole to 30mL of ethanol, under vigorous stirring, add 12g of SBA-15 molecular sieve, and stir at room temperature for 10h to fully disperse N-methylimidazole in the molecular sieve, then add solvent There is an ethanol solution of 0.11mol chloroacetic acid, stirred and reacted at 50°C for 24 hours, suction filtered, washed with ethanol 3 times, and the unreacted N-methylimidazole, chloroacetic acid, and the reaction products of the two that are only attached to the surface of the molecular sieve Fully washed and removed to obtain a white solid crude product, which is SBA-15 molecular sieve loaded with 1-acetic acid-3-methylimidazolium chloride salt;

[0037] (2) The white solid crude product obtained in step (1) was stirred and dispersed in 30 mL of dichloromethane, and then an appropriate amoun...

Embodiment 2

[0041] A preparation method of a molecular sieve gasoline desulfurizer loaded with functionalized ionic liquid, comprising the following steps:

[0042] (1) Add 0.12 mol of pyridine to 30 mL of ethanol, add 15 g of NaY molecular sieve under vigorous stirring, and stir at room temperature for 12 hours to fully disperse pyridine in the molecular sieve, then add 0.13 mol of 4-bromobutyric acid in ethanol Solution, stirred and reacted at 55°C for 22 hours, filtered with suction, washed 3 times with ethanol, fully washed and removed unreacted pyridine, 4-bromobutyric acid, and the reaction products of the two that were only attached to the surface of NaY molecular sieve, and obtained a white solid The crude product is NaY loaded with 1-butyric acid pyridinium bromide;

[0043] (2) Stir and disperse the white solid crude product obtained in step (1) in 40mL of dichloromethane, then add an appropriate amount of sulfuric acid dropwise, and react under reflux and stirring for 30h at 50...

Embodiment 3

[0047] A preparation method of a molecular sieve gasoline desulfurizer loaded with functionalized ionic liquid, comprising the following steps:

[0048] (1) Add 0.10mol of dodecyltrimethylammonium bromide to 30mL of ethanol, under vigorous stirring, add 16g of MCM-41 molecular sieve, and stir at room temperature for 10h to make the dodecyltrimethylammonium bromide solution After the molecular sieve is fully dispersed, filter with suction and wash with ethanol for 3 times, fully wash and remove the dodecyltrimethylammonium bromide that is only attached to the surface of the MCM-41 molecular sieve, and obtain a white solid crude product, which is the product loaded with ten Dialkyltrimethylammonium bromide MCM-41;

[0049] (2) Stir and disperse the white solid crude product obtained in step (1) in 50 mL of dichloromethane, then add an appropriate amount of phosphoric acid dropwise, and react under reflux and stirring for 36 h at 50° C. After the reaction, the reaction solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com