Preparation method of size-controllable nanoscale cubic-phase super-fine barium titanate powder

A fine barium titanate, nano-scale technology, applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problem of difficulty in obtaining dispersed ultrafine barium titanate powder, lengthy preparation process, non-concentrated particle size distribution, etc. problems, to achieve the effect of improving reactivity and reaction rate, reducing powder agglomeration, and narrow distribution range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

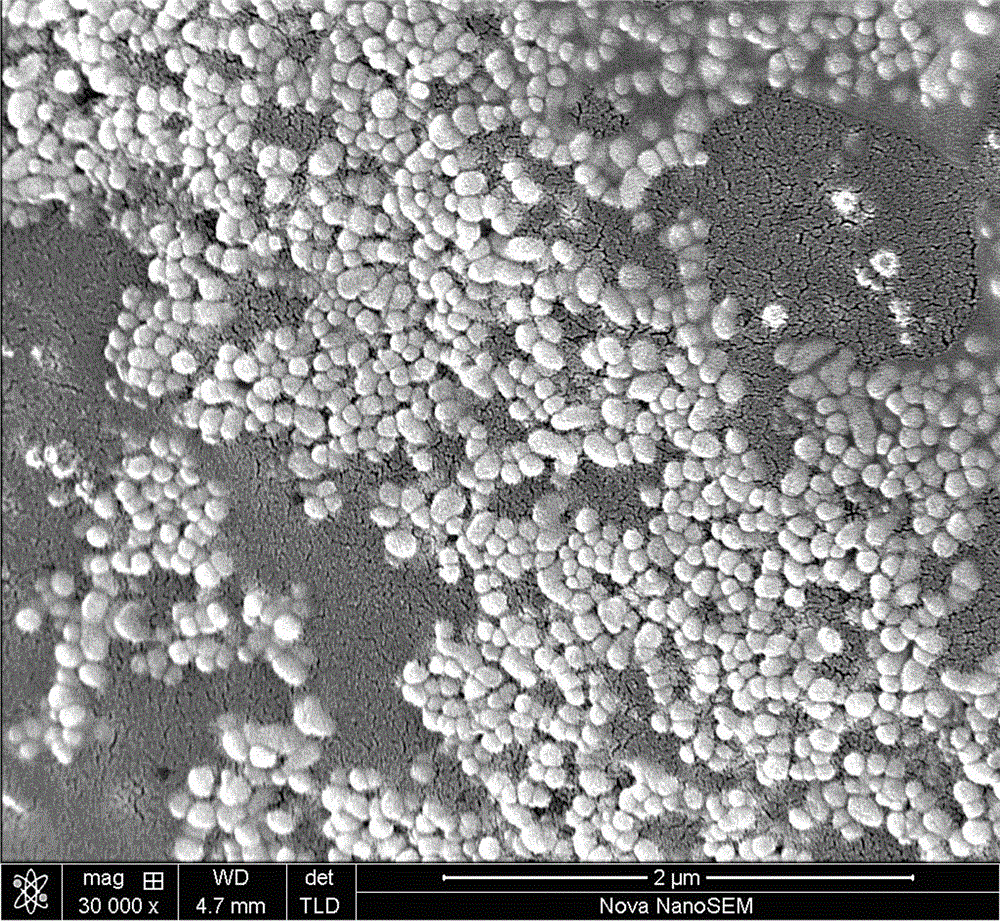

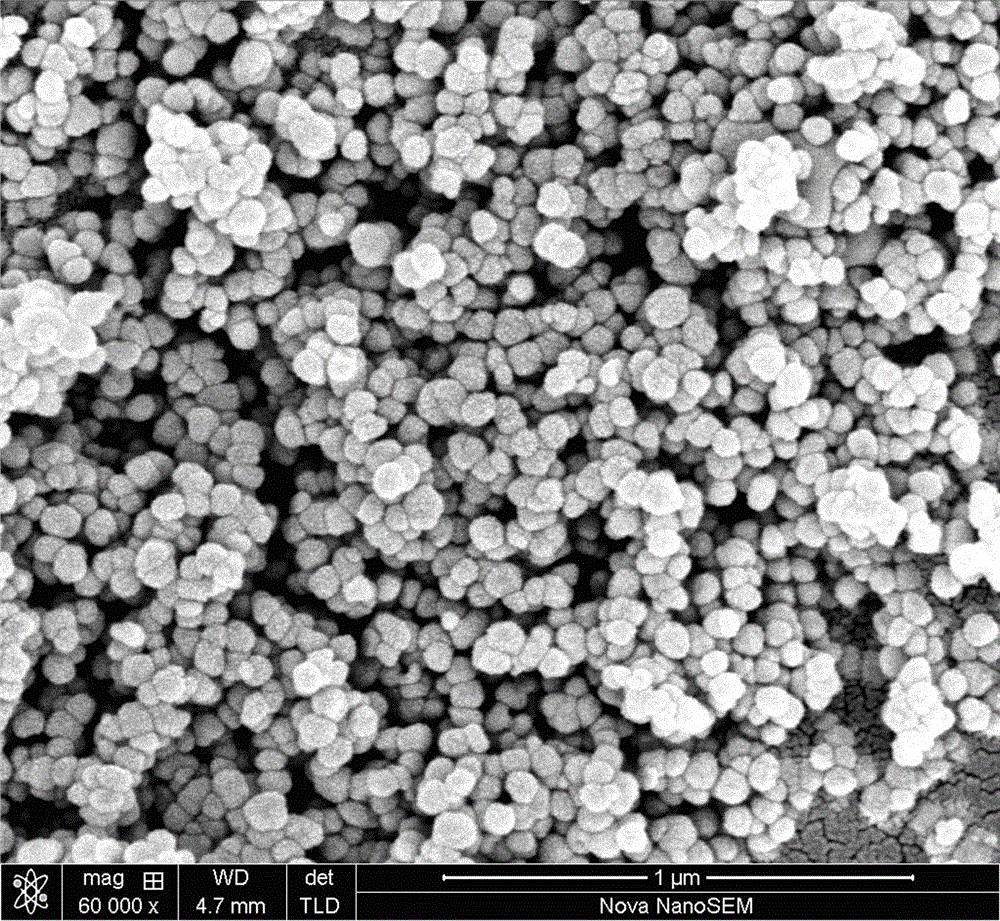

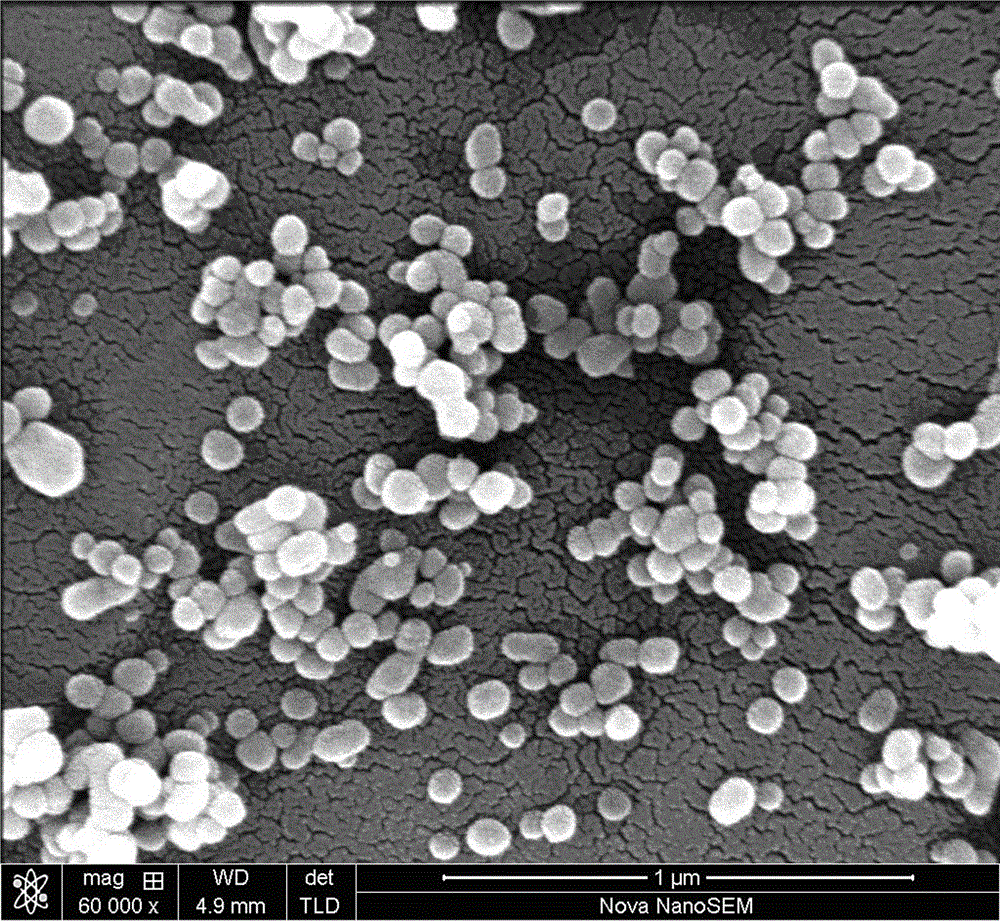

[0035] Weigh 2.0KgTiCl 4 , under the condition that the reaction temperature is lower than 30°C, slowly add it dropwise to the mixed solution containing 4.0Kg deionized water and 40g dispersant ethanol in the reaction kettle under constant stirring to obtain light yellow viscous TiOCl 2 Aqueous solution, the HCl gas generated during the process is absorbed by NaOH lye, and the solution after the exhaust gas is concentrated and crystallized to obtain industrial-grade NaCl crystals. Then the reaction temperature is less than 30 ℃ and the TiOCl 2 Add 6.0Kg of mineralizer ammonia water to the aqueous solution to make it NH 3 ·H 2 O: TiCl 4 The mass ratio is between 3.0:1.0, and the final pH of the reaction system is between 8-12, during which a white colloidal precipitate is formed. The precipitate was centrifuged and washed with deionized water until the chloride ion content was less than 100ppm. The washed white precipitate was then mixed with Ba(OH) 2 ·8H 2 O solid and w...

Embodiment approach 2

[0037]Weigh 2.0KgTiCl 4 , under the condition that the reaction temperature is lower than 30°C, slowly add it dropwise to the mixed solution containing 4.0kg deionized water and 200g ethanol under continuous stirring in the reactor to prepare light yellow viscous TiOCl 2 Aqueous solution, the HCl gas generated during the process is absorbed by NaOH lye, and the solution after the exhaust gas is concentrated and crystallized to obtain industrial-grade NaCl crystals. Then the reaction temperature is less than 30 ℃ and the TiOCl 2 Add 2.0Kg of ammonia water to the aqueous solution to make NH 3 ·H 2 O: TiCl 4 The mass ratio is 1.0:1.0, and the final pH of the reaction system is between 8-12, during which a white colloidal precipitate is formed. The precipitate was centrifuged and washed with deionized water until the chloride ion content was less than 100ppm. The washed white precipitate was then mixed with Ba(OH) 2 ·8H 2 O solid and water 15.0Kg, control the molar ratio of...

Embodiment approach 3

[0039] Weigh 2.0KgTiCl 4 , under the condition that the reaction temperature is lower than 30°C, slowly add it dropwise into 3.0Kg of deionized water under constant stirring in the reactor to obtain light yellow viscous TiOCl 2 Aqueous solution, the HCl gas generated during the process is absorbed by NaOH lye, and the solution after the exhaust gas is concentrated and crystallized to obtain industrial-grade NaCl crystals. Then the reaction temperature is less than 30 ℃ and the TiOCl 2 Add 4.0Kg of ammonia water to the aqueous solution to make NH 3 ·H 2 O: TiCl 4 The mass ratio is between 2.5:1.0, and the final pH of the reaction system is between 8-14, during which a white colloidal precipitate is formed. The precipitate was centrifuged and washed with deionized water until the chloride ion content was less than 50 ppm. The washed white precipitate was then mixed with Ba(NO 3 ) 2 Solid and water 20.0Kg, control the molar ratio of barium source and titanium source at 1.1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com