Flame-retardant thermal-insulation multilayer film

A multi-layer film and thermal insulation coating technology, applied in the field of flame retardant materials, can solve the problems of carcinogenic dioxins and the inability to meet the environmental protection of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

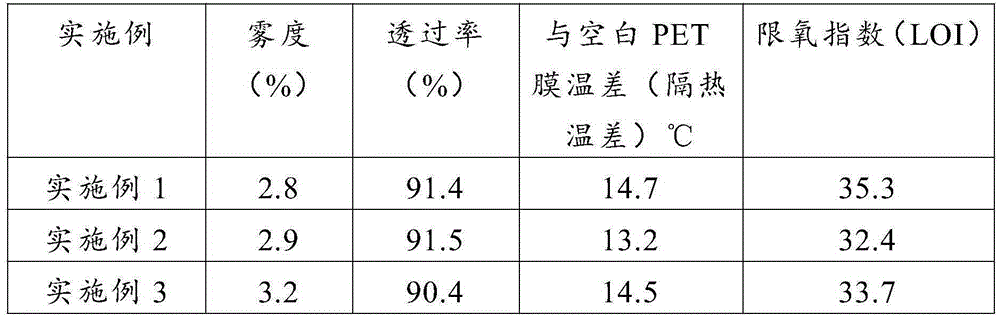

Examples

preparation example Construction

[0031] In the preparation process of the thermal insulation coating, the weight ratio of the nano-alumina, nano-ceria, gallium-doped zinc oxide, ceric acid yttrium-based inorganic pigment and polyurethane resin is preferably 5-10:5-8:5-8 :2-4:400-500, more preferably 6-9:6-8:5-7:3-4:420-480.

[0032] In the step of obtaining the heat-insulating nanocomposite slurry, the dispersion treatment specifically includes: dispersing at a speed of 300-500 rpm for 5-10 minutes; the ball mill treatment specifically includes: using a ball mill to grind for 20-30 minutes. The surface modification step specifically includes: adding a silane coupling agent drop by drop, wherein the silane coupling agent used in the present invention is preferably the silane coupling agent KH570.

[0033] In the first mixed solution, the weight ratio of ethanol, n-octanol, sodium citrate, polyethylene glycol and deionized water is preferably 30-50:6-15:3-7:3-7:40-60, More preferably, it is 40:10:5:4:50.

[0...

Embodiment 1

[0056] The preparation steps of gallium-doped zinc oxide are as follows:

[0057] Measure 20 parts by weight of zinc sulfate solution (1moL / L), place 10 parts by weight of gallium nitrate solution (0.2moL / L) in a beaker, place the flask on a magnetic stirrer to stir, adjust the temperature to 50°C, weigh Add 2-4 parts by weight of polyethylene glycol into a beaker, add ammonia solution dropwise to the beaker to obtain a precipitate, ultrasonically disperse the white precipitate for 20 minutes, continue the reaction for 20 minutes, stop stirring, and stand for aging at room temperature for 1 hour. Centrifuge the white precipitated product and wash it three times with deionized water and ethanol solution respectively. The precipitate is placed in an oven for 6 hours, and finally calcined in a muffle furnace at 200°C for two hours, and ground to obtain gallium-doped zinc oxide powder.

[0058] The preparation method of ceric acid yttrium series inorganic pigment comprises the ste...

Embodiment 2

[0076] The preparation steps of gallium-doped zinc oxide are as follows:

[0077] Measure 20 parts by weight of zinc sulfate solution (1moL / L), place 10 parts by weight of gallium nitrate solution (0.2moL / L) in a beaker, place the flask on a magnetic stirrer to stir, adjust the temperature to 50°C, weigh Add 3 parts by weight of polyethylene glycol into a beaker, add ammonia solution dropwise to the beaker to obtain a precipitate, ultrasonically disperse the white precipitate for 12 minutes, continue the reaction for 20 minutes, stop stirring, and leave it to age at room temperature for 1 hour. Centrifuge the white precipitated product and wash it three times with deionized water and ethanol solution respectively. The precipitate is placed in an oven for 6 hours, and finally calcined in a muffle furnace at 300°C for two hours, and ground to obtain gallium-doped zinc oxide powder.

[0078] The preparation method of ceric acid yttrium series inorganic pigment comprises the steps...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com