Anionic SBS emulsion, preparation method and application thereof

An anionic and emulsion technology, applied in coatings, asphalt coatings, etc., can solve the problems of complex preparation process, high equipment requirements, and high production costs, and achieve the effect of simple preparation process, low equipment requirements, and improved waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: the preparation of anionic SBS emulsion

[0024] (1) Preparation of SBS emulsion: dissolving styrene-butadiene-styrene block copolymer in n-hexane under stirring, and configuring it into a polymer solution with a concentration of 15wt%;

[0025] (2) Preparation of soap solution: configuration containing concentration is 4wt% rosin potassium, 0.5wt% carboxymethylcellulose sodium and 0.50wt% Na 2 SO 4 soap solution, adjust the PH value between 9 and 10;

[0026] (3) Preparation of anionic SBS emulsion: SBS emulsion and soap solution are mixed according to the weight ratio of 100:30, the SBS emulsion is added to the soap solution under stirring, dispersed and emulsified at room temperature; heated to 30-40°C, vacuum Adjust to 5-10kPa, distill under reduced pressure for 2h, and concentrate to obtain anionic SBS emulsion.

Embodiment 2

[0027] Embodiment 2: the preparation of anionic SBS emulsion

[0028] (1) Preparation of SBS emulsion: Dissolve styrene-butadiene-styrene block copolymer in a mixed solvent of n-hexane and cyclohexane under ultrasonic conditions, and configure a polymer solution with a concentration of 17wt%;

[0029](2) Preparation of soap solution: configuration containing concentration is 4wt% rosin potassium, 2wt% potassium oleate, 0.5wt% carboxymethylcellulose sodium and 0.50wt% Na 2 SO 4 soap solution, adjust the pH value between 10 and 11;

[0030] (3) Preparation of anionic SBS emulsion: SBS emulsion and soap solution are mixed according to the weight ratio of 100:20. Add soap solution to SBS emulsion under stirring, disperse and emulsify at room temperature; heat SBS emulsion to 30-40°C , adjusted the vacuum degree to 5-10kPa, distilled under reduced pressure for 2h, and concentrated to obtain SBS emulsion.

Embodiment 3

[0031] Embodiment 3: the preparation of anionic SBS emulsion

[0032] (1) Preparation of SBS emulsion: dissolving styrene-butadiene-styrene block copolymer in n-hexane under stirring, and configuring it into a polymer solution with a concentration of 20wt%;

[0033] (2) Preparation of soap solution: configuration containing concentration is 6wt% rosin potassium, 0.5wt% hydroxymethyl cellulose and 0.50wt% Na 2 SO 4 soap solution, adjust the pH value between 10 and 11;

[0034] (3) Preparation of anionic SBS emulsion: SBS emulsion and soap solution are proportioned according to a weight ratio of 100:20, the SBS emulsion is added to the soap solution under stirring, and dispersed and emulsified at room temperature;

[0035] (4) Heat the SBS emulsion to 30-40° C., adjust the vacuum degree to 5-10 kPa, distill under reduced pressure for 2 hours, and concentrate to obtain the SBS emulsion.

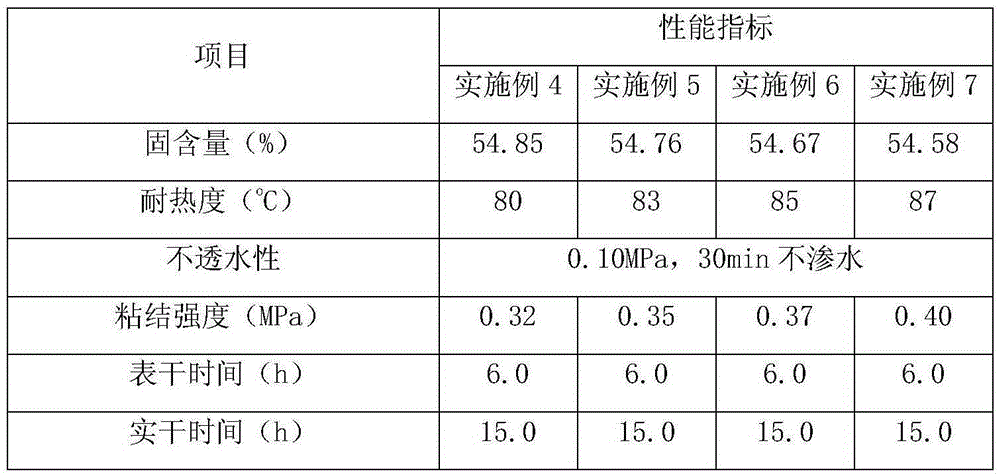

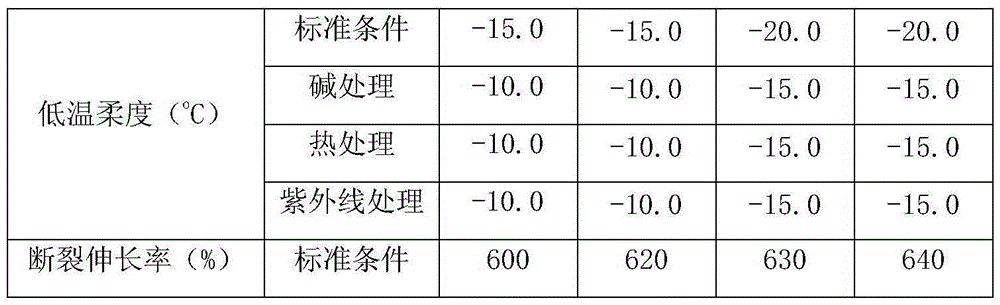

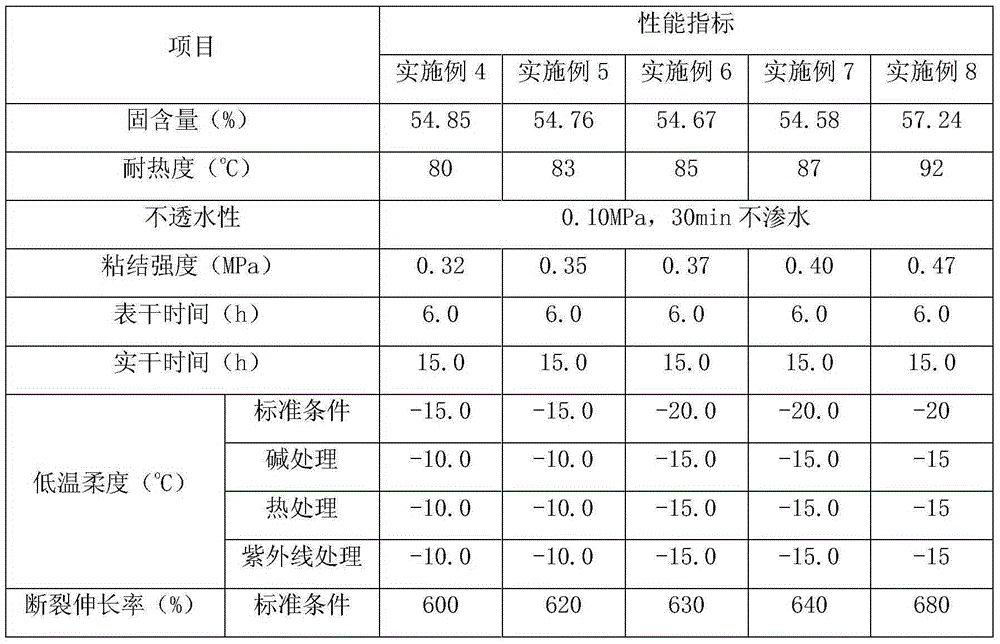

[0036] See Table 1 for the performance test results of the SBS emulsion prepared in Examp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Heat resistance | aaaaa | aaaaa |

| Low temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com