Wiring board with through electrode, method for producing same, and semiconductor device

A technology of penetrating electrodes and wiring substrates, used in semiconductor devices, printed circuit manufacturing, multi-layer circuit manufacturing, etc. Excellent electrical properties, improved reliability, and improved adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

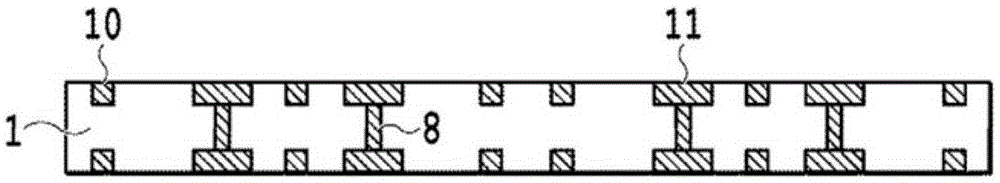

[0062] Next, examples based on the embodiments of the present invention are produced and studied.

[0063] First, an example of producing a glass wiring board with a through-hole electrode will be described. That is, an alkali-free glass having a thickness of 300 μm was prepared, and a photocurable SU-8 resist layer (negative epoxy resin mount) capable of forming a thick film of 25 μm was formed by the spin coating method. After exposing using a predetermined mask, patterning is performed using PGMEA (propylene glycol methyl ether acetate) in a developing solution. The backside is also patterned by the same method.

[0064] Then, by SF 6 The gas performs dry etching to form wiring and pads on the front surface of the glass. As specifications, the width of the wiring portion was 5 μm, the pad portion was 100 μm square, and the depth direction was 20 μm. The back is also processed in the same way. After removing the resist pattern by ashing, a seed layer is formed by copper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com