Breast implant three-dimensional structure and rapid forming method thereof

A three-dimensional structure and implant technology, applied in prosthetics, medical science, etc., can solve the problems of unsustainable effect, fat cell necrosis, etc., and achieve the effect of enhancing viability and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

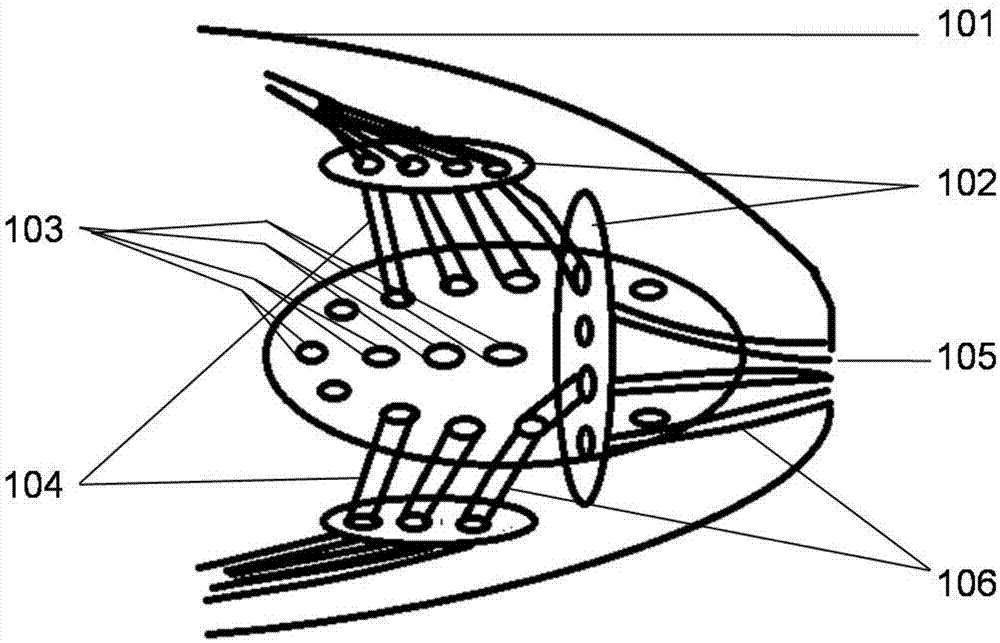

Image

Examples

Embodiment 1

[0038] 1) Material preparation

[0039] Take 0.1g of sodium alginate, 1g of fibrinogen and 20g of gelatin and place them in 100mL of culture medium to dissolve them completely, and sterilize them to obtain gelatin, sodium alginate and fibrinogen solutions; prepare 0.01g / ml of calcium chloride Aqueous solution is used as sodium alginate cross-linking agent, 0.01g / ml thrombin is used as fibrinogen cross-linking agent; endothelial cells (ECs), nerve cells and adipose stem cells (ADSCs) are extracted, cultured and passaged; endothelial cells (ECs), nerve cells Cells and adipose stem cells (ADSCs) were mixed with gelatin, sodium alginate, and fibrinogen solutions, and the density of endothelial cells was 1×10 4 cells / mL, the density of nerve cells was 1×10 5 cells / mL, the density of adipose-derived stem cells was 2×10 6 individual / mL; add 1% endothelial cell growth factor solution in the sodium alginate solution containing adipose-derived stem cells; dissolve the degradable polyc...

Embodiment 2

[0047] 1) Material preparation

[0048] Take 0.1g of sodium alginate, 20g of fibrinogen and 4g of gelatin and place them in 100mL culture medium to dissolve them completely, and then sterilize them to obtain gelatin, sodium alginate and fibrinogen solutions; prepare 1g / ml calcium chloride aqueous solution As a sodium alginate cross-linking agent, 1g / ml thrombin as a fibrinogen cross-linking agent; extract patient bone marrow stem cells (BDSCs), culture and passage; part of the bone marrow stem cells (BDSCs) induced transformation into endothelial cells and nerve cells; The remaining part of bone marrow stem cells (BDSCs), endothelial cells (ECs) and nerve cells were mixed with gelatin, sodium alginate and fibrinogen solution respectively, and the density of bone marrow stem cells (BDSCs) was 1×10 3 cells / mL, the density of endothelial cells (ECs) was 1×10 4 cells / mL, the density of nerve cells was 1×10 5 pcs / mL; dissolving degradable polyurethane in 1,4-dioxane to obtain a s...

Embodiment 3

[0056] 1) Material preparation

[0057] Take 2g of sodium alginate, 1g of collagen and 10g of gelatin and place them in 100mL of culture medium to dissolve them completely, and sterilize them to obtain sodium alginate, collagen and gelatin solutions; prepare 10g / ml of calcium chloride aqueous solution as sodium alginate gelatin Induced pluripotent stem cells were extracted from patients, cultured and passaged; the induced pluripotent stem cells were mixed with sodium alginate, collagen, and gelatin solutions and divided into three parts; the induced pluripotent stem cells and natural polymer solutions were divided into three parts Add 1%, 5%, 10% by volume of endothelial cell growth factor, nerve cell growth factor, adipocyte growth factor; dissolve degradable lactic acid and glycolic acid copolymer (PLGA) in tetraethylene glycol to obtain mass volume concentration It is a 20% synthetic polymer solution, which is sterilized and ready for use; cell culture fluid is prepared.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com