CdxZn1-xS nanowire compound photocatalyst and preparing method and application thereof

A cdxzn1-xs and nanowire technology, which is applied in the preparation of amino compounds, chemical instruments and methods, and the preparation of organic compounds, can solve undeveloped problems and achieve the effect of fast reaction speed and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

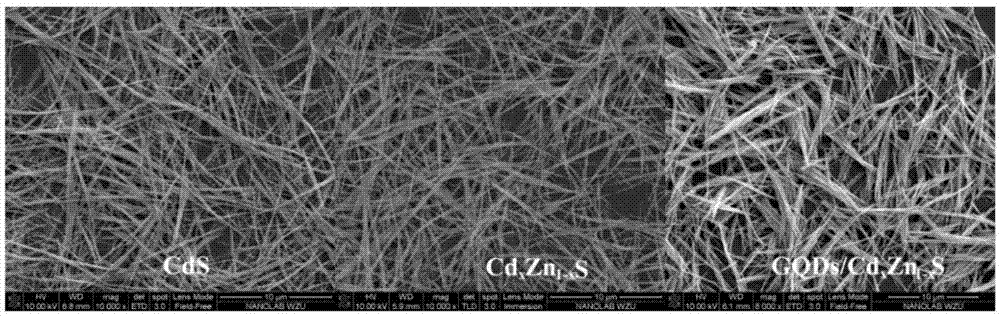

[0052] Under stirring conditions, 1mmolCd(Ac) 2 2H 2 O and 2 mmol of copper reagent were dissolved in 34 mL of ethylenediamine and 6 mL of n-dodecanethiol mixed solvent and magnetic stirring was continued for 10 minutes. Transfer this solution to a 50 mL polytetrafluoroethylene-lined autoclave. The reaction kettle was placed in a blast drying oven at 180°C for 48 hours. After the reaction was completed, when the temperature dropped to room temperature, the product was centrifuged, washed alternately with absolute ethanol and deionized water, and dried to obtain CdS nanowire powder. Take 0.0864g of CdS nanowires and mix them with 0.6mmol of zinc nitrate pentahydrate, add them into 40mL of ethylene glycol under the condition of stirring, stir for 10 minutes, and ultrasonically mix. Then the mixed solution was transferred into a 50mL reaction kettle, and placed in a 160°C forced-air drying oven to react for 6 hours. After the reaction, the product was centrifuged, washed alte...

Embodiment 2

[0060] As an application of the present invention:

[0061] Put 30mL of 20mg / L p-nitroaniline solution in a beaker, add 40mg of ammonium formate under stirring conditions, and then weigh 20mg of GQDs / Cd x Zn 1-x S composite photocatalyst, ultrasonic for 3 minutes to make the catalyst uniformly dispersed in the reaction solution. The reaction solution was magnetically stirred for 2 hours in the dark, so that the catalyst and the reactant reached adsorption equilibrium. Irradiate with visible light with a wavelength of 500W xenon lamp (λ>420nm), and the distance between the light source and the reaction system is 12cm. Samples were taken every 2 minutes, and the ultraviolet absorption of the supernatant was measured after centrifugation. As the reaction progressed, the color of the solution gradually changed from yellow to colorless.

[0062] like Image 6As shown, p-nitroaniline can be completely converted into p-phenylenediamine within 6 min. Further prolonging the illum...

Embodiment 3

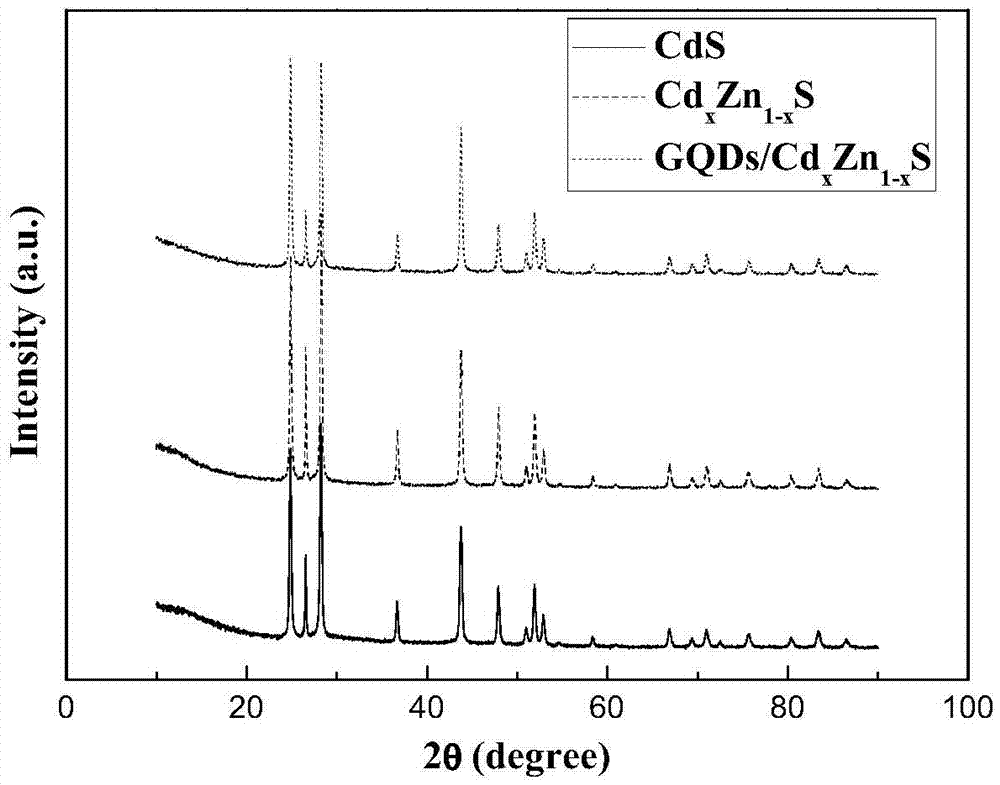

[0064] Add 20mg of the same mass of CdS nanowires, Cd with different doping zinc concentration x Zn 1-x S nanowires and GQDs / Cd with different loadings x Zn 1-x S nanowires, the photocatalytic test conditions are the same as in Example 2, and the relative activity of different samples is studied. The result is as Figure 7 Shown, GQDs / Cd x Zn 1-x S nanowire composites than single GQDs / Cd x Zn 1-x S all have better activity. When the amount of GQDs was 0.21 (wt), the activity of the composite catalyst was the best.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com