Polyurethane grouting material for repairing roadbed-bottom culvert defects

A technology of grouting material and polyurethane, which is applied in the field of grouting materials, can solve the problems of increasing the drying shrinkage rate of the consolidated body, premature aging and degradation of the consolidated body, poor resistance to acid hydrolysis and corrosion, etc., and achieve good instant curing efficiency , outstanding alkali resistance, good hydrolytic stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

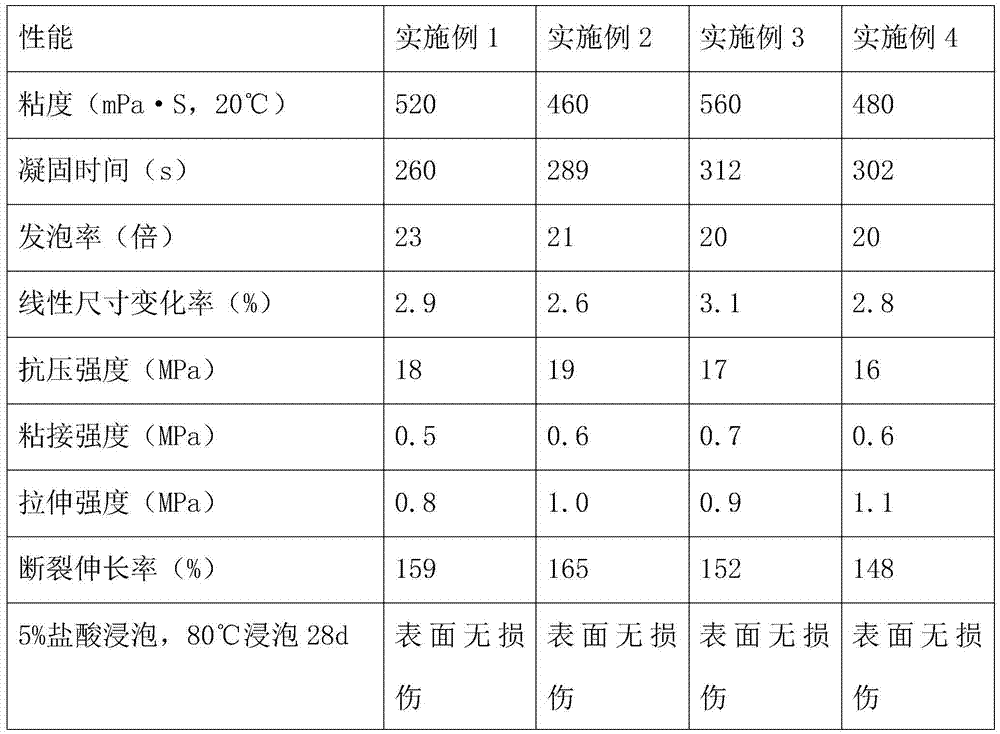

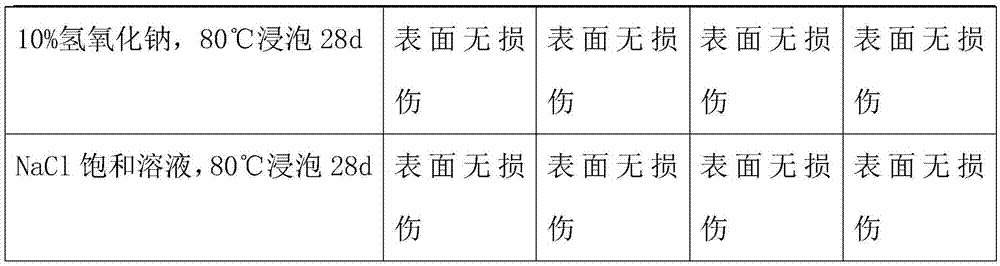

Examples

Embodiment 1

[0020] The polyurethane grouting material used for the repair of karst caves at the bottom of the roadbed described in this embodiment, its raw materials include by weight: 60 parts of polyurethane prepolymer, 25 parts of modified phenolic resin, 1 part of organic montmorillonite, triphosphate 15 parts of (β-chloroethyl) ester, 2 parts of quaternary ammonium polyurethane antistatic agent, 30 parts of dioctyl phthalate, 2 parts of polyether modified polysiloxane, 1 part of catalyst, 10 parts of acetone ;

[0021] Wherein, the preparation method of the polyurethane prepolymer includes: adding polyether polyol, polyester polyol and soybean oil polyol into the reaction kettle, dehydrating for 2 hours under the condition of vacuum degree of -0.08MPa and temperature of 120°C, cooling To 65°C, inject nitrogen to restore normal pressure, add polyisocyanate, keep stirring under nitrogen atmosphere for 0.5h, then raise the temperature to 90°C, stir and react for 2h, after the reaction i...

Embodiment 2

[0024] The polyurethane grouting material used for the repair of karst caves at the bottom of the roadbed described in this embodiment, its raw materials include by weight: 80 parts of polyurethane prepolymer, 15 parts of modified phenolic resin, 10 parts of organic montmorillonite, triphosphate 5 parts of (β-chloroethyl) ester, 3 parts of quaternary ammonium polyurethane antistatic agent, 5 parts of dinonyl phthalate, 10 parts of polyvinylpyrrolidone, 0.05 part of catalyst, 35 parts of butanone;

[0025]Wherein, the preparation method of the polyurethane prepolymer includes: adding polyether polyol, polyester polyol and soybean oil polyol into the reaction kettle, dehydrating for 3 hours under the condition of vacuum degree of -0.1MPa and temperature of 110°C, cooling to 55°C, inject nitrogen to restore the normal pressure, add polyisocyanate, heat and stir under nitrogen atmosphere for 1 hour, then raise the temperature to 80°C, stir and react for 3 hours, after the reaction ...

Embodiment 3

[0028] The polyurethane grouting material used for repairing karst caves at the bottom of the roadbed described in this embodiment, its raw materials include by weight: 70 parts of polyurethane prepolymer, 20 parts of modified phenolic resin, 5 parts of organic montmorillonite, triphosphate 10 parts of (β-chloroethyl) ester, 2.5 parts of quaternary ammonium polyurethane antistatic agent, 17 parts of diisodecyl phthalate, 806 parts of Tween, 0.5 parts of catalyst, 22 parts of ethyl acetate;

[0029] Wherein, the preparation method of the polyurethane prepolymer comprises: adding polyether polyol, polyester polyol and soybean oil polyol into a reaction kettle, dehydrating for 2.5 hours at a vacuum degree of -0.09MPa and a temperature of 115°C, Cool down to 60°C, inject nitrogen to restore normal pressure, add polyisocyanate, heat and stir under nitrogen atmosphere for 0.7h, then raise the temperature to 85°C, stir and react for 2.5h, after the reaction is completed, cool down to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com