Streptomyces calculus genetically engineered bacterium and constructing method and application thereof

A technology of Streptomyces albicans and genetically engineered bacteria, applied in the field of genetic engineering, can solve the problem of few actinomycetes, and achieve the effects of reducing the obstruction of intracellular enzymes, improving utilization, and having good industrial application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

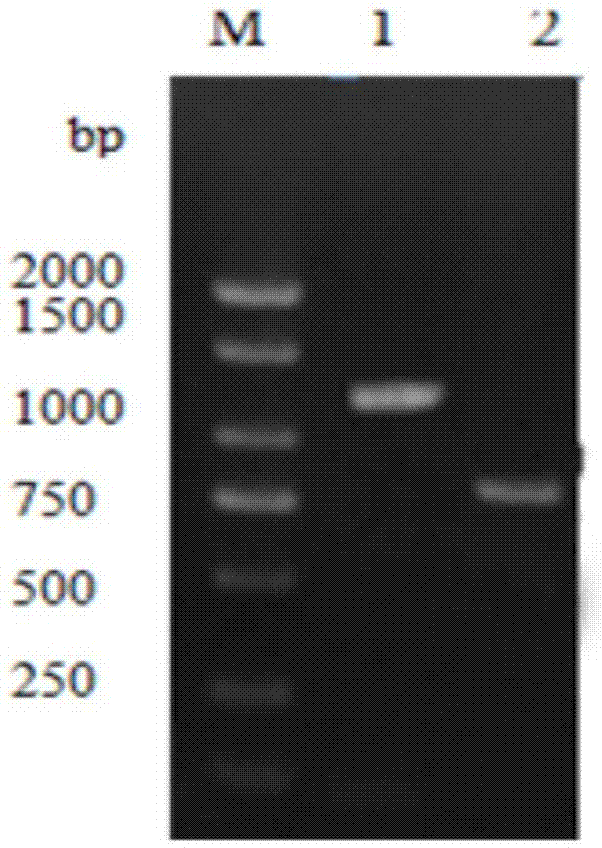

[0025] Example 1: Cloning of ammonium transporter gene (amtB gene) and construction of genetically engineered bacteria.

[0026] 1.1 PCR amplification of the ammonium transporter gene (amtB gene).

[0027] The genomic DNA of S. albulusPD-1 in logarithmic growth phase was extracted with GenomicDNA Purification Kit (Takara, Dalian), and the obtained genomic DNA was detected by 2% (20 g / L) agarose gel electrophoresis.

[0028] Use VectorNTI software to design the following two primers:

[0029] Primer 1: 5′-CCATATGG CATATG GTGAACCTCTCAGGTTCCGATGA-3′

[0030] (The underline is the NdeI restriction site)

[0031] Primer 2: 5′-CTCTAGAG AGATCT CTACTTCTGCCGCTTGTAGAAGG-3′

[0032] (The underline is the XbaI restriction site)

[0033] The obtained genomic DNA of S. albulusPD-1 was used as a template to amplify the target gene fragment.

[0034] PCR system: 2 μL of genomic DNA, 1 μL each of primer 1 and primer 2, 2 μL of dNTP, 10× exTaq buffer (containing Mg 2+ ) 2.5 μL, exTaq ...

Embodiment 2

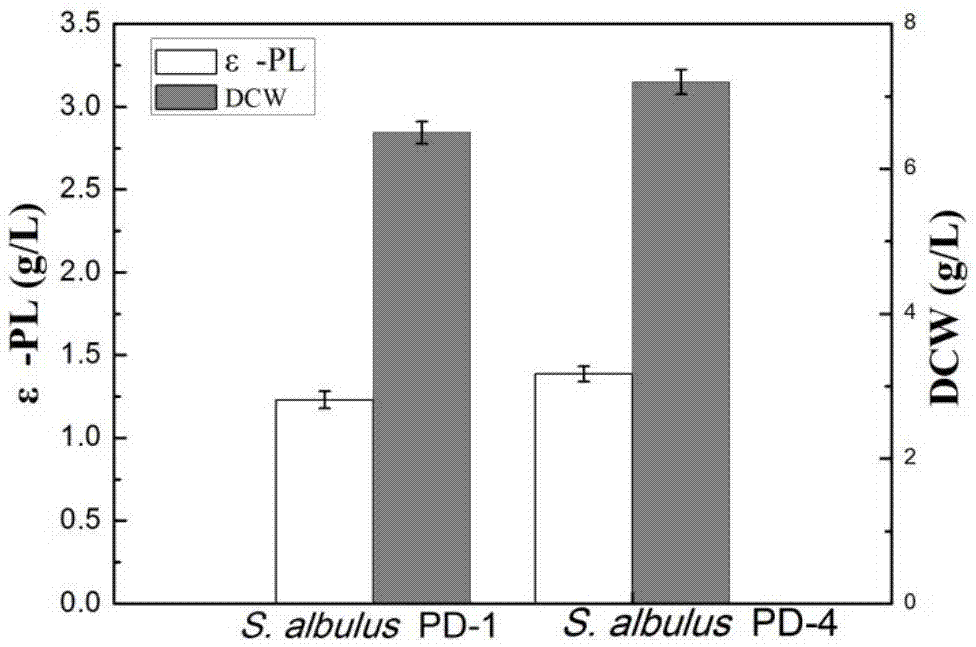

[0052] Example 2: Verification of high-efficiency nitrogen source using recombinant bacteria shake flask fermentation.

[0053] Prepare seed liquid 100mL, culture medium is M3G liquid culture medium (Glucose50g / L, YeastExtract5g / L, (NH 4 ) 2 SO 4 10g / L, K 2 HPO 4 0.8g / L, KH 2 PO 4 1.36g / L, MgSO 4 ·7H 2 O0.5g / L, FeSO 4 ·7H 2 O0.03g / L, ZnSO 4 ·7H 2 (00.04g / L, pH6.8), put into 500mL wide-mouth Erlenmeyer flask after being sterilized by high pressure at 121℃ for 15min. Insert a loop of genetically engineered bacteria Streptomycesalbulus PD-4 into the seed solution with an inoculation loop, and place it on a shaker at 30°C at a speed of 200rpm for overnight culture for 3 days. Fermentation results such as figure 2 As shown, the yield of shake flask fermentation reached ε-PL1.38g / L for three days, the dry weight (DCW) of bacteria per unit volume could reach 7.2g / L, the S.albulusPD-1 control could reach 1.23g / L, and DCW could up to 6.5g / L. Compared with the control, ε...

Embodiment 3

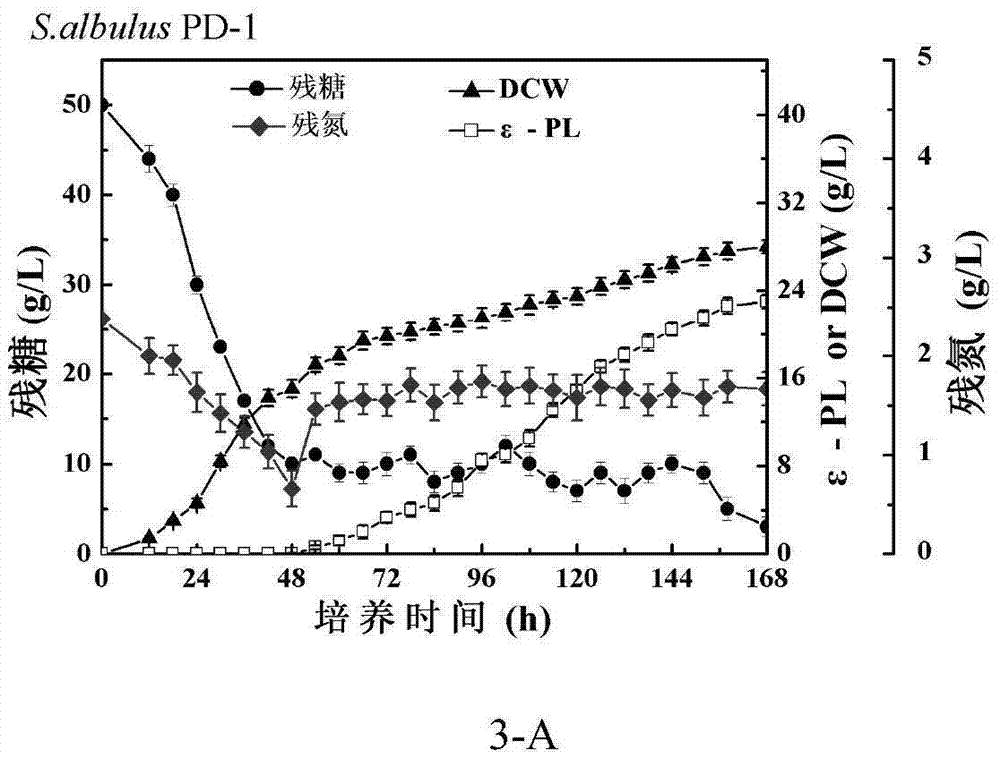

[0054] Example 3: Two-stage fermentation optimization of C / N in shake flasks using recombinant bacteria as a high-efficiency nitrogen source.

[0055] After culturing the engineering bacteria S.albulusPD-4 and the control bacteria S.albulusPD-130°C at 200rpm for one day, centrifuge at 6000rpm for 5min, collect the bacteria, wash and transfer to cultures with a glucose concentration of 10g / L and different ammonium sulfate concentrations. In base I, control C / N at 2.36:1, 3:1, 4.71:1, 9.17:1, 11.5:1, 16.5:1, and 23:1 to continue fermentation for 7 days, and take samples to measure the ε-PL output at the end of fermentation. At the end of the fermentation, it was found that, as shown in Table 1, the ε-PL of the original strain reached the maximum when the optimal C / N was 3:1 in the two-stage fermentation process of the shake flask, and the maximum value was 1.236g / L, which was supplied under the original feeding process The C / N supply of S.albulusPD-1 with a certain concentration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com