Analytical method for determining tellurium in high-selenium tellurium slag

An analysis method, the technology of tellurium slag, applied in the field of chemical analysis, can solve the problems of difficult accurate measurement of tellurium content, difficult analysis of results, and long time consumption, so as to avoid the impact on the test, ensure accuracy, acceleration rate and completeness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

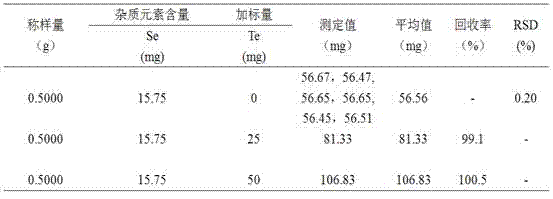

Embodiment 1

[0020] (1) Accurately weigh 0.5000g of a certain tellurium slag sample in a 400mL beaker, pour a small amount of water to moisten the sample, add 15mL 15mol / L concentrated nitric acid, heat and boil until the sample is completely dissolved, add 15mL sulfuric acid (1+1) and heat to After the sulfuric acid fumes are removed and cooled, diluted with a small amount of water, add 10mL of 6.8mol / L hydrobromic acid, continue to heat until the sulfuric acid fumes are exhausted, and then remove, add 12mol / L hydrochloric acid 10mL and boil until the solution is steamed to nearly dry. Add 20mL hydrochloric acid (1+1) to flush with water to about 150mL, heat the solution to near boiling to dissolve the salts, add dropwise 50g / L silver sulfate solution until there is no silver chloride precipitation in the solution, filter with medium speed filter paper, and retain the filtrate ;

[0021] (2) Add 0.01mol / L potassium permanganate standard solution to the above-mentioned filtrate until the colo...

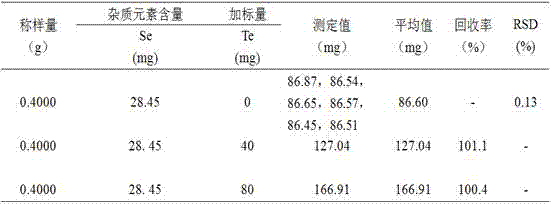

Embodiment 2

[0025] (1) Accurately weigh 0.4000g of a certain tellurium slag sample into a 400mL beaker, pour a small amount of water to moisten the sample, add 15mL of 15mol / L concentrated nitric acid, heat and boil until the sample is completely dissolved, add 15mL sulfuric acid (1+1) to heat to Sulfuric acid fumes, take off and cool, dilute with a small amount of water, add 10mL of 6.8mol / L hydrobromic acid, continue to heat until the sulfuric acid fumes are exhausted, then remove, add 12mol / L of 10mL hydrochloric acid and boil until the solution is steamed to nearly dry After that, add 20mL hydrochloric acid (1+1) to rinse to about 150mL, heat the solution to near boiling to dissolve the salts, add 50g / L silver sulfate solution dropwise until there is no silver chloride precipitation in the solution, filter with medium speed filter paper , Keep the filtrate;

[0026] (2) Add 0.01mol / L potassium permanganate standard solution to the above-mentioned filtrate until the color of the solution ...

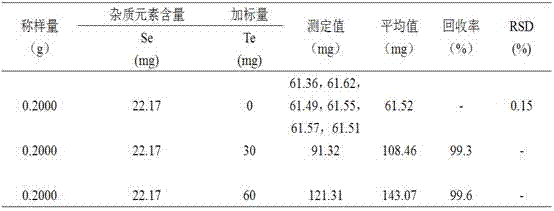

Embodiment 3

[0030] (1) Accurately weigh 0.3000g of a certain tellurium slag sample into a 400mL beaker, pour a small amount of water to moisten the sample, add 10mL 15mol / L concentrated nitric acid, heat and boil until the sample is completely dissolved, add 10mL sulfuric acid (1+1) and heat to Sulfuric acid fumes, take off and cool, dilute with a small amount of water, add 10mL of 6.8mol / L hydrobromic acid, continue heating until the sulfuric acid fumes are exhausted, then remove, add 12mol / L of hydrochloric acid 10mL, heat and boil until the solution is almost dry After that, add 20mL hydrochloric acid (1+1) to flush with water to about 150mL, heat the solution to near boiling to dissolve the salts, add 50g / L silver sulfate solution dropwise until there is no silver chloride precipitation in the solution, filter with medium speed filter paper, Retain the filtrate;

[0031] (2) Add 0.01mol / L potassium permanganate standard solution to the above-mentioned filtrate until the color of the solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com