Method for preparing lithium iron phosphate positive electrode material using polycyclic aromatic hydrocarbon resin as carbon source

A polycyclic aromatic hydrocarbon resin, lithium iron phosphate technology, used in battery electrodes, structural parts, electrical components, etc., can solve the problems of unstable asphalt structure, poor product stability, complex asphalt components, etc., and achieve a high softening point. , low production cost, good electrical performance consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation method of polycyclic aromatic hydrocarbon resin comprises the following steps:

[0041]1) Using heavy aromatics in heavy residual oil as a raw material, using at least one of a compound having a vinyl structure, phenol, and aldehyde as a cross-linking agent, under the action of an acidic catalyst and an inorganic salt catalyst, conduct a condensation reaction to generate B Order condensation polycyclic polynuclear aromatic hydrocarbon resin;

[0042] 2) curing the B-stage condensed polycyclic polynuclear aromatic hydrocarbon resin to obtain the C-stage heat-resistant condensed polycyclic polynuclear aromatic hydrocarbon resin.

[0043] In the step 2), the volume fraction of the ethanol solution is 50-100%; the pelletizing time is 1-10 hours.

[0044] In the step 3), the temperature of the oven is 60-90°C.

[0045] In the step 4), the rate of temperature rise from room temperature to 370-390°C is 3-8°C / min; the rate of temperature rise from 370-390°C to...

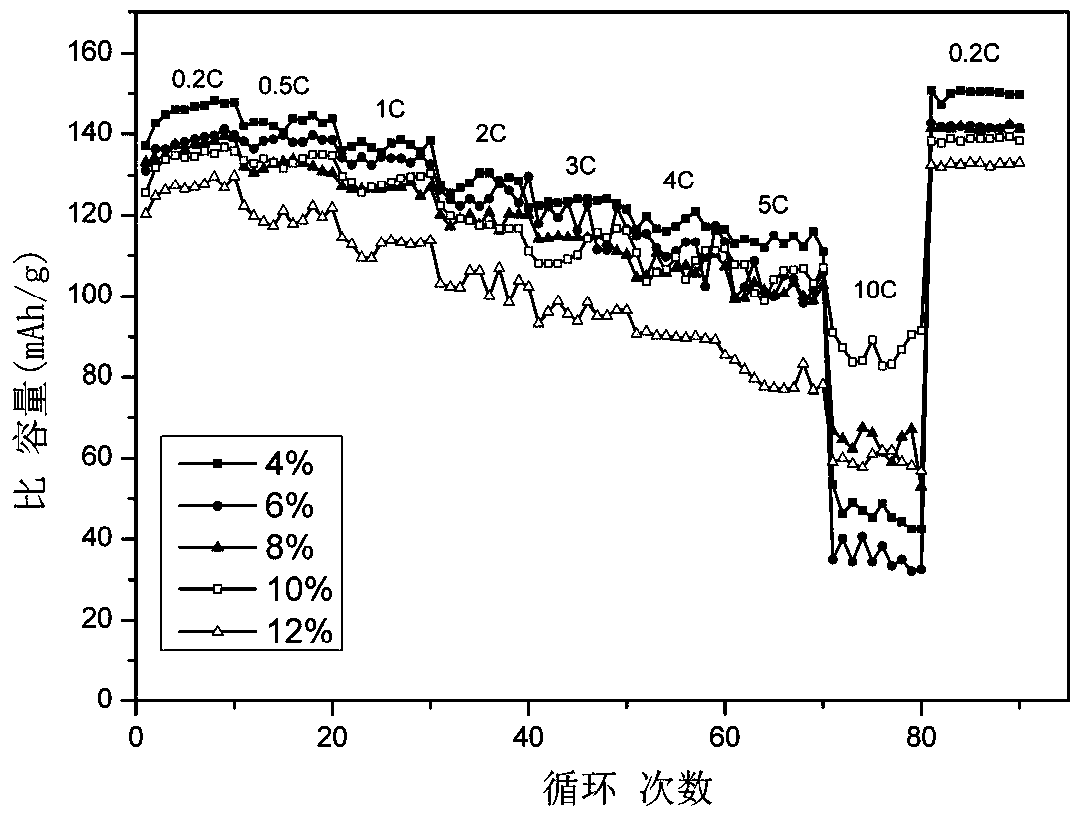

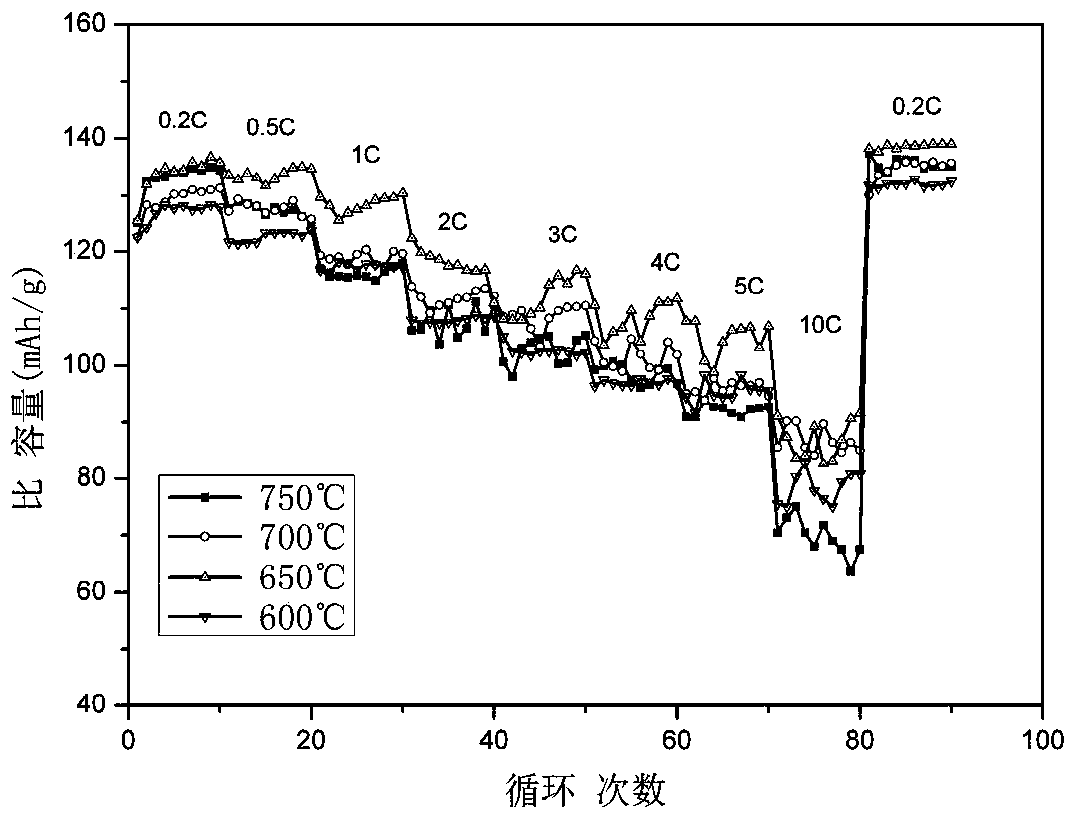

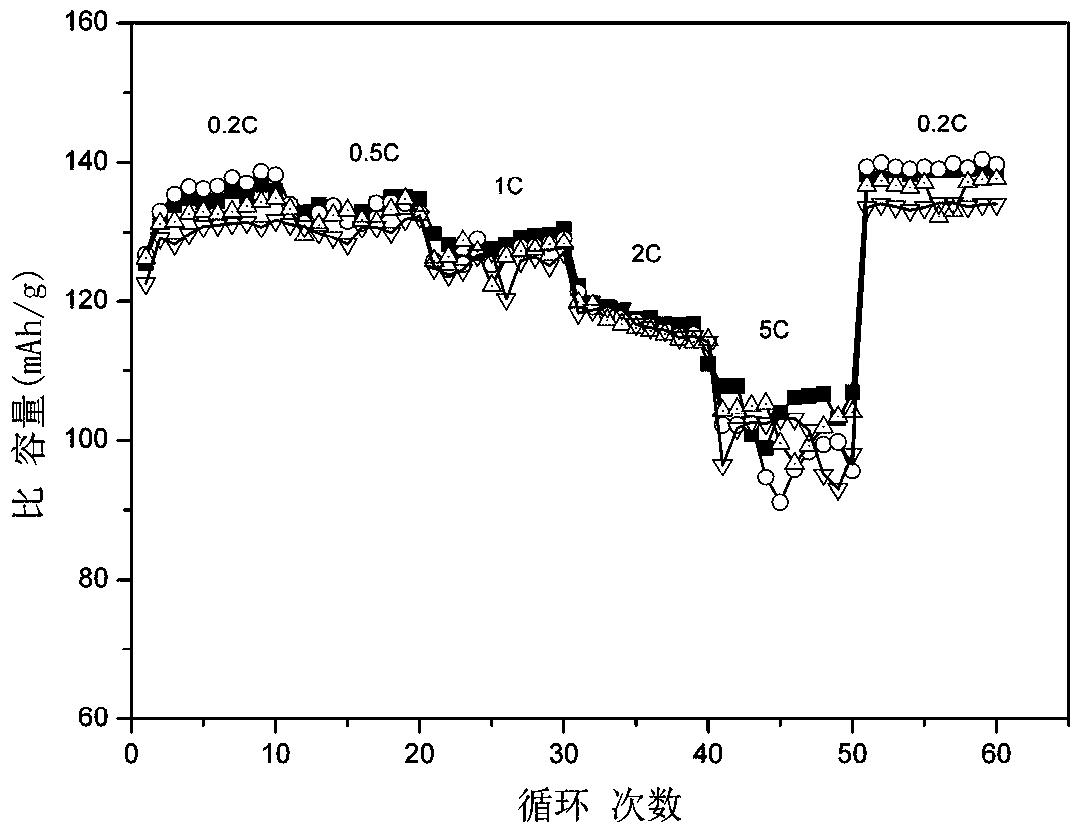

Embodiment 1

[0062] A kind of method that utilizes polycyclic aromatic hydrocarbon resin to prepare lithium iron phosphate cathode material as carbon source, comprises the following steps:

[0063] 1) Weigh iron phosphate and lithium hydroxide in a weight ratio of 1:4; mix iron phosphate, lithium hydroxide and polycyclic aromatic hydrocarbon resins evenly; obtain a mixture; wherein, the weight of polycyclic aromatic hydrocarbon resins accounts for 10% of the total amount of raw materials added 4%;

[0064] 2) Add the mixture to the ethanol solution, and perform wet pelletizing in a planetary ball mill at a rotational speed of 300r / min for 6 hours; obtain a precursor slurry containing ball milling;

[0065] 3) Put the ball-milled precursor slurry obtained in step 2) into an oven at a temperature of 80°C for drying, then grind and sieve to obtain the precursor;

[0066] 4) Place the precursor prepared in step 3) in a high-temperature furnace. Under the protection of nitrogen, the high-tempe...

Embodiment 2

[0068] A method for preparing a lithium iron phosphate positive electrode material using a polycyclic aromatic hydrocarbon resin as a carbon source, comprising the following steps:

[0069] 1) Weigh iron phosphate and lithium hydroxide in a weight ratio of 1:4; mix iron phosphate, lithium hydroxide and polycyclic aromatic hydrocarbon resins evenly; obtain a mixture; wherein, the weight of polycyclic aromatic hydrocarbon resins accounts for 10% of the total amount of raw materials added 10%;

[0070] 2) Add the mixture to the ethanol solution, and perform wet pelletizing in a planetary ball mill at a rotational speed of 300r / min for 6 hours; obtain a precursor slurry containing ball milling;

[0071] 3) Put the ball-milled precursor slurry obtained in step 2) into an oven at a temperature of 80°C for drying, then grind and sieve to obtain the precursor;

[0072] 4) Place the precursor prepared in step 3) in a high-temperature furnace. Under the protection of nitrogen, the high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com