The preparation method of ambroxoxalbutamol enteric-coated granules

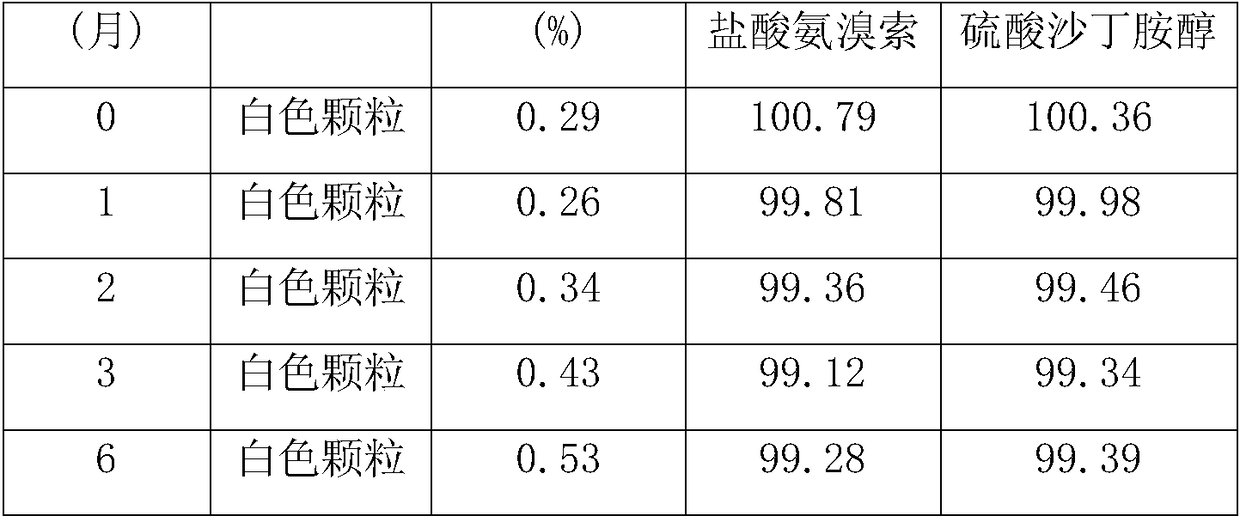

A technology of ambroxoxalbutamol and salbutamol sulfate, which is applied in the field of ambroxoxalbutamol enteric-coated granules and its preparation, can solve the problems of unsatisfactory product stability, no report of enteric-coated granules, and easy production of by-products, etc., and achieve active The effect of increasing the content of ingredients, treating respiratory diseases, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] prescription:

[0050] The core is made of the following components by weight:

[0051] Salbutamol sulfate: 12g;

[0052] Ambroxol hydrochloride: 15g;

[0053] Poloxamer 188: 8g;

[0054] Meglumine: 12g;

[0055] Mannitol: 18g;

[0056] Lactose: 60g;

[0057] Sodium carboxymethyl starch: 5g;

[0058] Povidone: Appropriate amount.

[0059] The enteric coating layer is made of the following components by weight: 15 g of cellulose acetate phthalate.

[0060] Preparation:

[0061] 1) Weigh the raw and auxiliary materials of the prescription amount, pass through a 100-mesh sieve for subsequent use;

[0062] 2) Add distilled water to the sieved povidone and cellulose acetate phthalate respectively to make a binder solution and a coating solution;

[0063] 3) Mix the sieved salbutamol sulfate, ambroxol hydrochloride, poloxamer 188, meglumine, mannitol, lactose and carboxymethyl starch sodium in equal increments, and add the above adhesive solution to prepare into soft...

Embodiment 2

[0067] prescription:

[0068] Core:

[0069] Salbutamol sulfate: 10g;

[0070] Ambroxol hydrochloride: 15g;

[0071] Poloxamer 188: 5g;

[0072] Meglumine: 15g;

[0073] Mannitol: 15g;

[0074] Dextrin: 80g;

[0075] Microcrystalline cellulose: 2g;

[0076] Hypromellose: Appropriate amount.

[0077] Coating layer: 10 g of cellulose acetate trimellitate.

[0078] Preparation:

[0079] 1) Weigh the raw and auxiliary materials of the prescription amount, pass through a 100-mesh sieve for subsequent use;

[0080] 2) Take the sieved hypromellose and cellulose acetate trimellitate and add distilled water respectively to make a binder solution and a coating solution;

[0081] 3) Mix the sieved salbutamol sulfate, ambroxol hydrochloride, poloxamer 188, meglumine, mannitol, dextrin and microcrystalline cellulose in equal increments, and add the above adhesive solution to prepare into soft material;

[0082] 4) After granulating with a 40-mesh sieve, dry at 60°C for 30 minut...

Embodiment 3

[0085] prescription:

[0086] Core:

[0087] Salbutamol sulfate: 15g;

[0088] Ambroxol hydrochloride: 20g;

[0089] Poloxamer 188: 10g;

[0090] Meglumine: 12g;

[0091] Mannitol: 20g;

[0092] Starch: 60g;

[0093] Microcrystalline cellulose: 4g;

[0094] Povidone: Appropriate amount.

[0095] Coating layer: 20 g of hydroxypropyl cellulose phthalate.

[0096] Preparation:

[0097] 1) Weigh the raw and auxiliary materials of the prescription amount, pass through a 100-mesh sieve for subsequent use;

[0098] 2) Take povidone and hydroxypropyl cellulose phthalate after sieving and add distilled water respectively to make binder solution and coating solution;

[0099] 3) Mix the sieved albuterol sulfate, ambroxol hydrochloride, poloxamer 188, meglumine, mannitol, starch and microcrystalline cellulose in equal increments, and add the above binder solution to prepare soft material;

[0100] 4) After granulating with a 40-mesh sieve, dry at 60°C for 60 minutes, pass thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com