Technology for preparing high-quality sulfuric acid from non-ferrous metal smelting flue gas

A technology for smelting flue gas and non-ferrous metals, which is applied in the direction of non-metallic elements, sulfur trioxide/sulfuric acid, sulfur compounds, etc., can solve the one-time investment and operation cost problems such as high power consumption, water consumption or steam consumption of desulfurizer, and achieve Low one-time investment and operating costs, reduced impurity content, and obvious effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

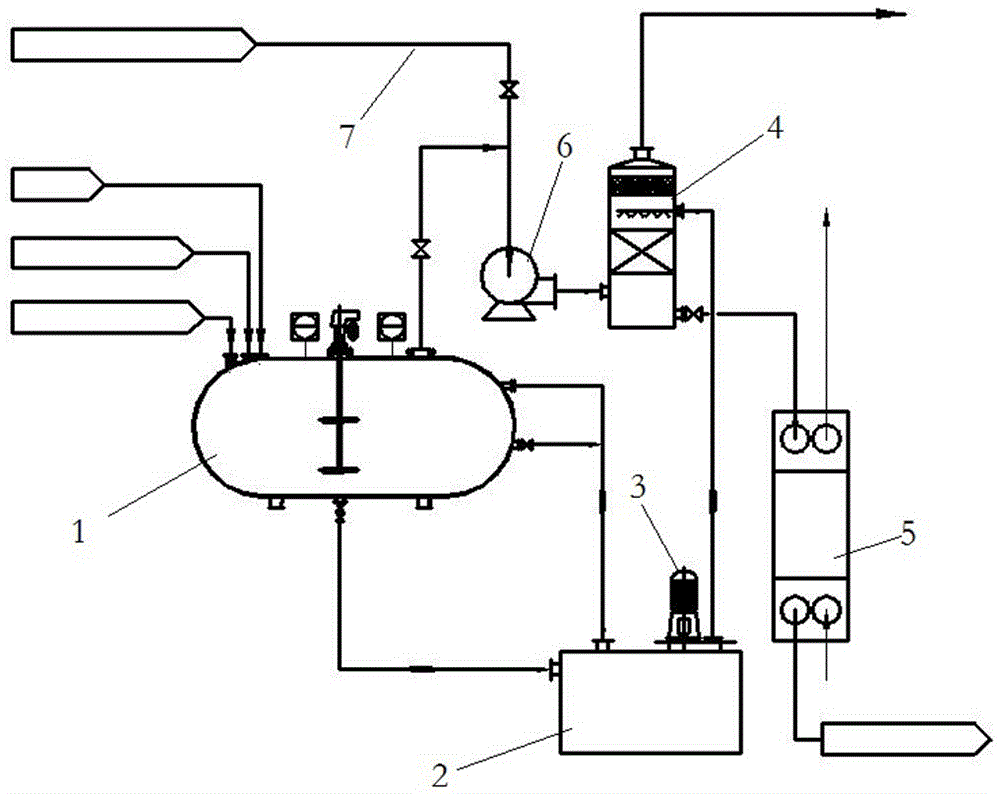

[0019] This embodiment provides a process for producing high-quality sulfuric acid from non-ferrous metal smelting flue gas. The device used in this process is as follows, including a sulfuric acid decolorization reaction kettle 1, a sulfuric acid storage tank 2, a sulfuric acid pump 3, a washing tower 4, and a cooler connected in sequence. 5; the upper part of the washing tower 4 is connected to the sulfuric acid pump 3 through a pipeline, the lower part of the washing tower 4 is connected to the cooler 5 through a pipeline, and the lower part of the washing tower 4 is also connected with the acid-making tail gas pipe 7, and the acid-making tail gas pipe 7 passes through Fan 6 is connected to the bottom of washing tower 4; Wherein, fan 6 is a booster fan, washing tower 4 is a packed tower, sulfuric acid storage tank 2 is a sulfuric acid underground storage tank, and sulfuric acid decolorization reaction still 1 is provided with water inlet, acid inlet and A decolorant port is ...

Embodiment 2

[0023] With the device of embodiment 1, the processing flow is 12m 3 Concentrated sulfuric acid with a mass concentration of 98.5% per hour, the contained ash does not meet the qualified product index, and the transparency and chroma do not reach the first-class product index; 2 The concentration is 450mg / m 3 , exceeding the current emission standard limit.

[0024] After the device was in operation, the various indicators of the sulfuric acid produced in this embodiment had reached the first-class products, and the SO in the tail gas discharged from the chimney to the atmosphere 2 The concentration is far lower than the limit value in the standard, which is 40mg / m 3 , the desulfurization rate was 91%, and no dense smoke was seen.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com