Method for making alfalfa rhizobium inoculant and rhizobium inoculant made through same and application thereof

An alfalfa rhizobia inoculum and alfalfa rhizobia technology are applied in the field of agricultural microorganisms, which can solve the problems that rhizobia are not suitable for industrialized production and processing, the shelf life of inoculum products is short, and the nitrogen-fixing efficiency of rhizobia is low, so as to achieve high-efficiency survival and good mobility. , the effect of high effective number of viable bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

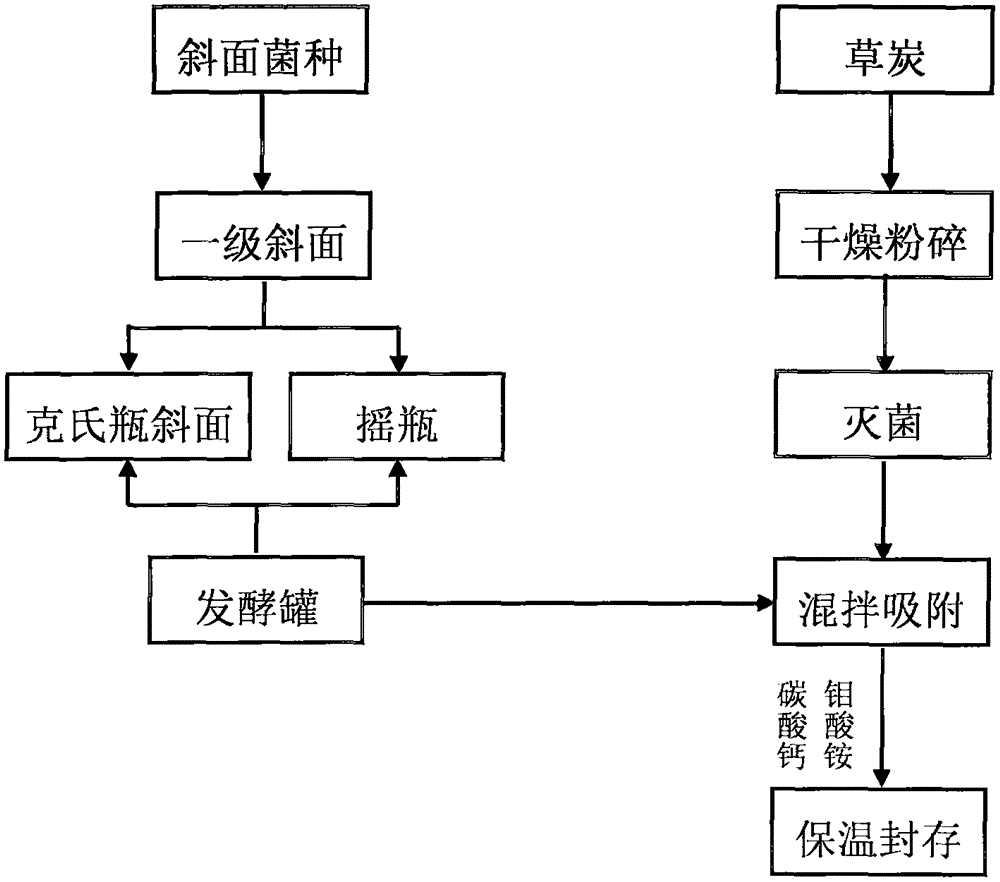

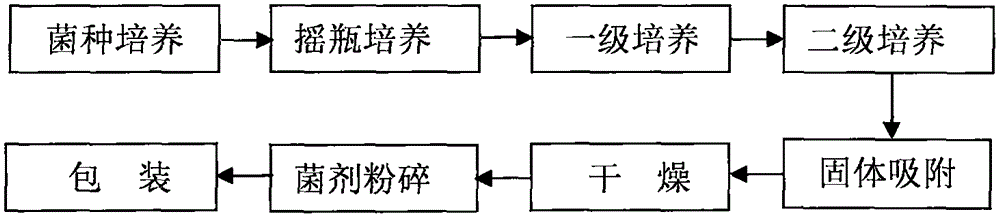

Method used

Image

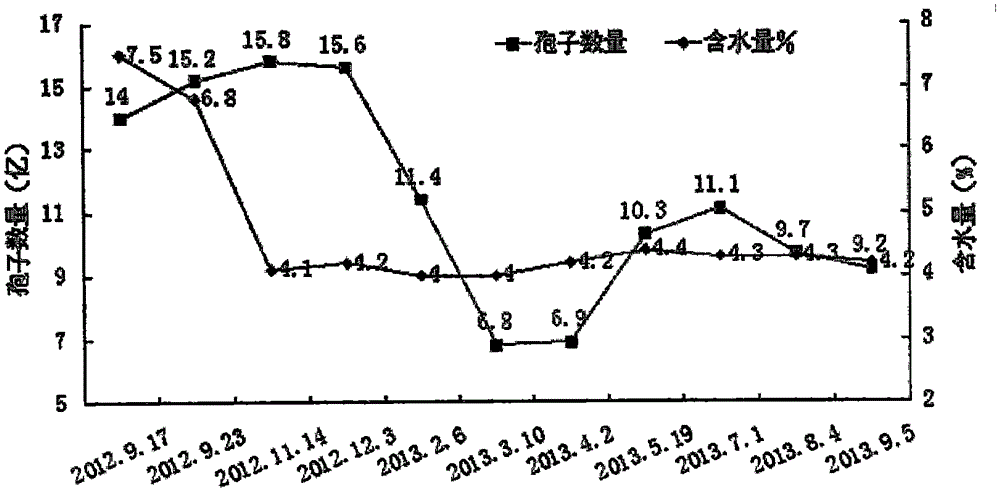

Examples

Embodiment 1

[0066] Embodiment 1 strain culture

[0067] The present embodiment adopts YMA agar slant culture method, and concrete method and culture medium formula are as follows:

[0068] (1) Production of YMA agar medium: Weigh potassium dihydrogen phosphate (KH 2 PO 4 ) 0.25g; Magnesium sulfate heptahydrate (MgSO 4 ·7H 2 O) 0.1g; Sodium chloride (NaCl) 0.05g; Mannitol (C 6 h 14 o 6 ) 5g; yeast powder 0.4g; agar 10g; add 500ml of distilled water and stir well, heat until boiling, so that the medium is fully dissolved. Transfer the culture medium to the test tube while it is hot through the funnel (the filling volume accounts for about 1 / 4 of the test tube height). After the packaging is completed, seal it with a silica gel stopper, then tie 7 test tubes into a bundle, and wrap the silica gel stopper of the test tube with parafilm and kraft paper.

[0069] (2) Sterilization of YMA agar medium: Sterilize in a sterilizing pot at 121.5°C for half an hour. During the sterilization, a...

Embodiment 2

[0072] Embodiment 2 Shake flask culture

[0073] The present embodiment adopts yeast-glycerin medium culture method, and specific method and medium formula are as follows:

[0074] (1) prepare yeast-glycerol medium, formula is glycerol 20g; Yeast powder 2.2g; Dipotassium hydrogen phosphate (K 2 HPO 4 ) 1.2g; diammonium hydrogen phosphate [(NH 4 )HPO 4 ] 1.0g; Magnesium sulfate heptahydrate (MgSO 4 ·7H 2 O) 0.7g; Calcium chloride dihydrate (CaCl 2H 2 O) 0.16g; Ferric chloride (FeCl 3 ) 0.0083g; manganese sulfate heptahydrate (MnSO 4 ·7H 2 O) 0.008g; Boric acid (H 3 BO 5 ) 0.01g; Sodium molybdate (Na 2 MoO 4 2H 2 O) 0.01g; defoamer (tributyl phosphate) 0.05ml; water 1000ml, fully stir evenly, transfer the solution to a 500ml triangular flask with a beaker, 200ml for each triangular flask, use sealing film and kraft paper after subpackaging Bandage.

[0075] (2) Yeast-glycerin medium is sterilized, put the yeast-glycerin medium into the Erlenmeyer flask for sterili...

Embodiment 3 1

[0078] Example 3 primary culture

[0079] In this embodiment, a fermenter is used to carry out primary culture, and the specific steps are as follows:

[0080] (1) Sterilize the empty fermenter.

[0081] (2) Prepare glycerol medium: take by weighing respectively with balance: glycerol 400g, yeast powder 44g, dipotassium hydrogen phosphate (K 2 HPO 4 ) 24g, diammonium hydrogen phosphate [(NH 4 )HPO 4 ] 20g, magnesium sulfate heptahydrate (MgSO 4 ·7H 2 O) 14g, calcium chloride dihydrate (CaCl 2H 2 O) 3.2g, ferric chloride (FeCl 3 ) 0.166g, manganese sulfate heptahydrate (MnSO 4 ·7H 2 O) 0.16g, boric acid (H 3 BO 5 ) 0.2g, sodium molybdate (Na 2 MoO 4 2H 2 O) 0.2g, defoamer (tributyl phosphate) 1mL, demineralized water 20L, fully stir and dissolve the above medium, and add it to a 30L fermenter.

[0082] (3) Sterilization of the fermenter culture medium: the fermenter was sterilized at 121.5° C. for half an hour, and then cooled.

[0083] (4) Culture medium inocul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com