Carbon dioxide infrared hollow-core fiber laser and manufacturing method thereof

A technology of hollow-core fiber and carbon dioxide, applied in the direction of lasers, laser components, phonon exciters, etc., to improve transmission accuracy and stability, simplify structure, and avoid poor optical coupling and instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

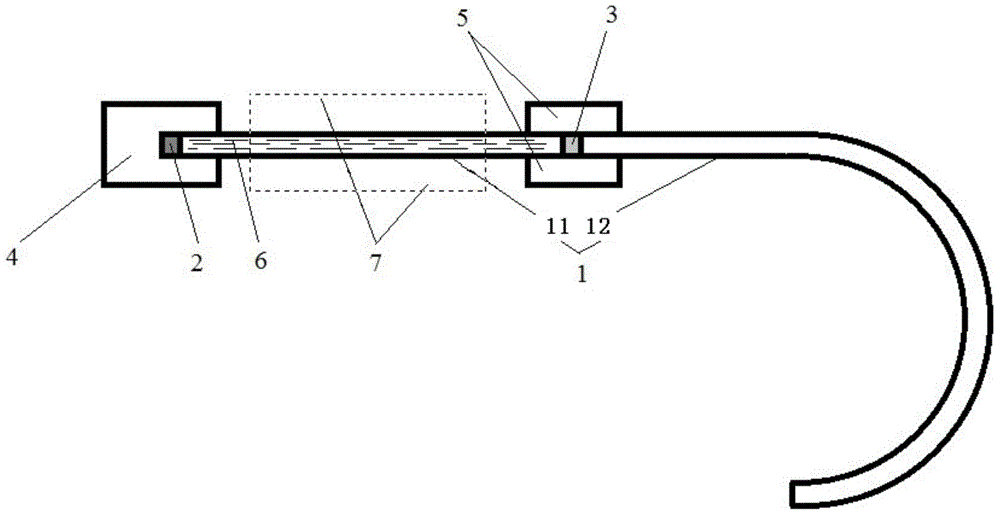

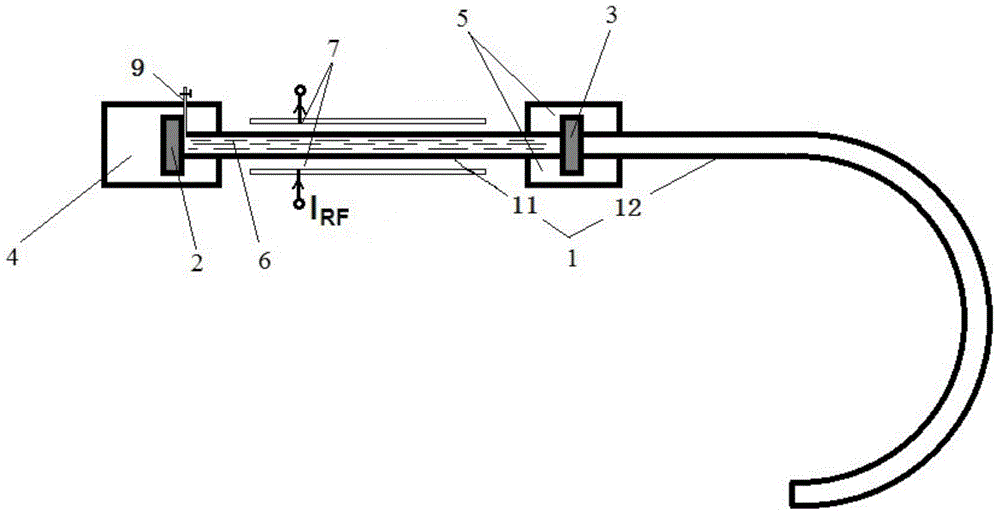

[0050] refer to figure 2 The hollow core fiber 1 of this specific embodiment is a quartz glass capillary hollow fiber 1 with a germanium oxide reflective film formed on the inner surface. The inner diameter of the fiber is 1.3 mm, the wall thickness is 0.07 mm, the germanium oxide film is 12 microns thick, and the length is 2.5 meters. Cut the hollow-core fiber into two sections with a length of 1.5 meters and 1 meter, which are respectively used as the resonant cavity 11 and the conducting part 12 . The total reflection mirror 2 is a gold-plated quartz reflection mirror, and the half reflection mirror 3 is a partial reflection mirror made of gallium arsenide. The total reflection mirror 2 and the half reflection mirror 3 are processed into discs with an outer diameter of 5 mm. The total reflection mirror 2 is embedded in the first ferrule 4 with a plane concave circular hole with an inner diameter of 5 mm, and inserted into one end of the resonant cavity 11 to realize the c...

Embodiment 2

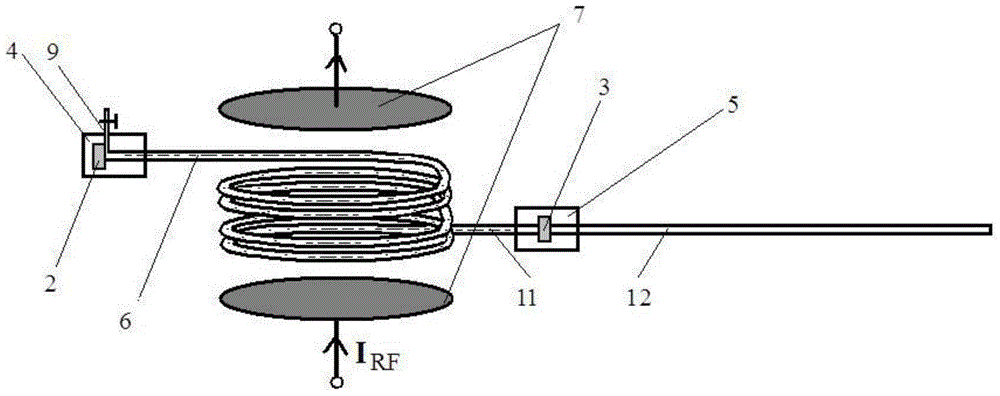

[0052] refer to image 3 The hollow-core fiber 1 of this specific embodiment is a quartz glass capillary hollow-core fiber with a germanium oxide reflection film formed on the inner surface. In order to shorten the size of the laser, the resonant cavity 11 is wound into a winding arrangement by utilizing the flexibility of the hollow-core fiber. The winding resonant cavity 11 can prolong the excited length of the gas working substance 6 and improve the CO 2 The laser output power of the laser can be reduced, while the volume of the resonant cavity 11 can still be kept small.

[0053] The resonant cavity 11 can be wound by using the hollow-core optical fiber 1 in the first embodiment above. In order to further reduce the volume of the winding-type ground resonator 11, the inner diameter and wall thickness of the hollow-core optical fiber 1 are further reduced in this embodiment. The inner diameter of the hollow-core optical fiber 1 is 0.8 millimeters, and the wall thickness is...

Embodiment 3

[0058] refer to Figure 4 The hollow-core optical fiber 1 of this specific embodiment is an alumina total reflection hollow-core optical fiber, and the resonant cavity 11 is coiled and arranged on the inner sleeve of the inner and outer sleeve-type nickel capacitor electrodes by utilizing the flexibility of the hollow-core optical fiber. The arrangement of the inner and outer sleeve-type capacitive electrodes can make it easier to fix the winding position of the hollow-core fiber, and at the same time, the radio frequency signal covers the hollow-core fiber more fully, and the working material in the hollow-core fiber 1 is more fully stimulated. The winding resonant cavity 11 can prolong the excited length of the gas working substance 6 and improve the CO 2 The laser output power of the laser can be reduced, while the volume of the resonant cavity 11 can still be kept small.

[0059]The resonant cavity 11 can also be wound by using the hollow-core optical fiber 1 in the first...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inner diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Inner diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com