Doped quantum dot catalyst, preparation method thereof, hydrogen production system comprising doped quantum dot catalyst, and hydrogen production method

A technology of quantum dots and catalysts, which is applied in the field of hydrogen production systems of quantum dot catalysts, can solve the problems of poor stability, difficult to control the loading, and large particles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

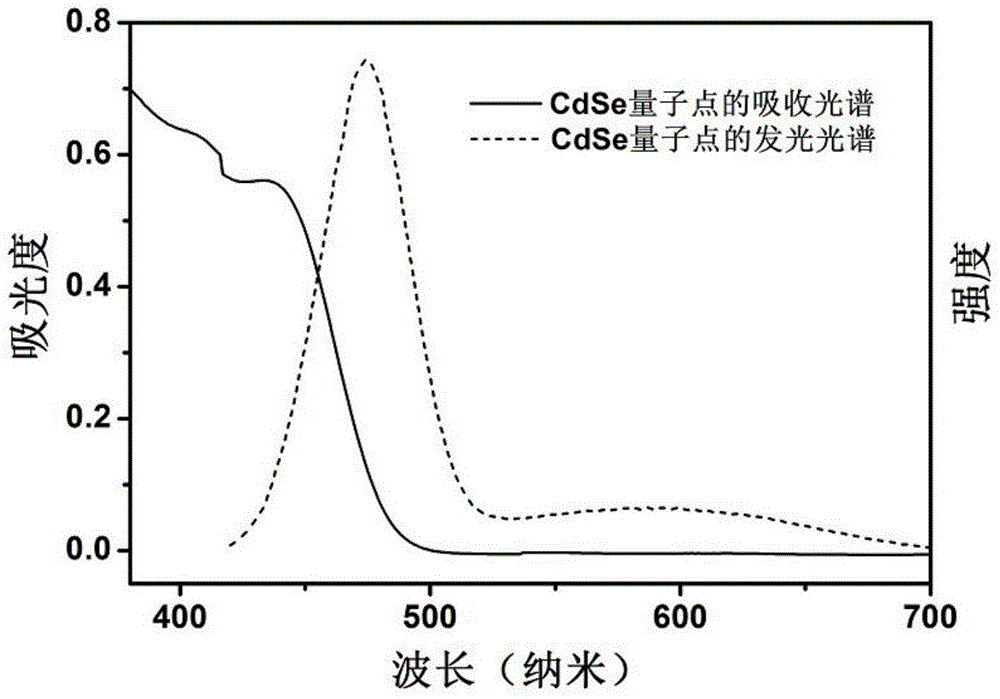

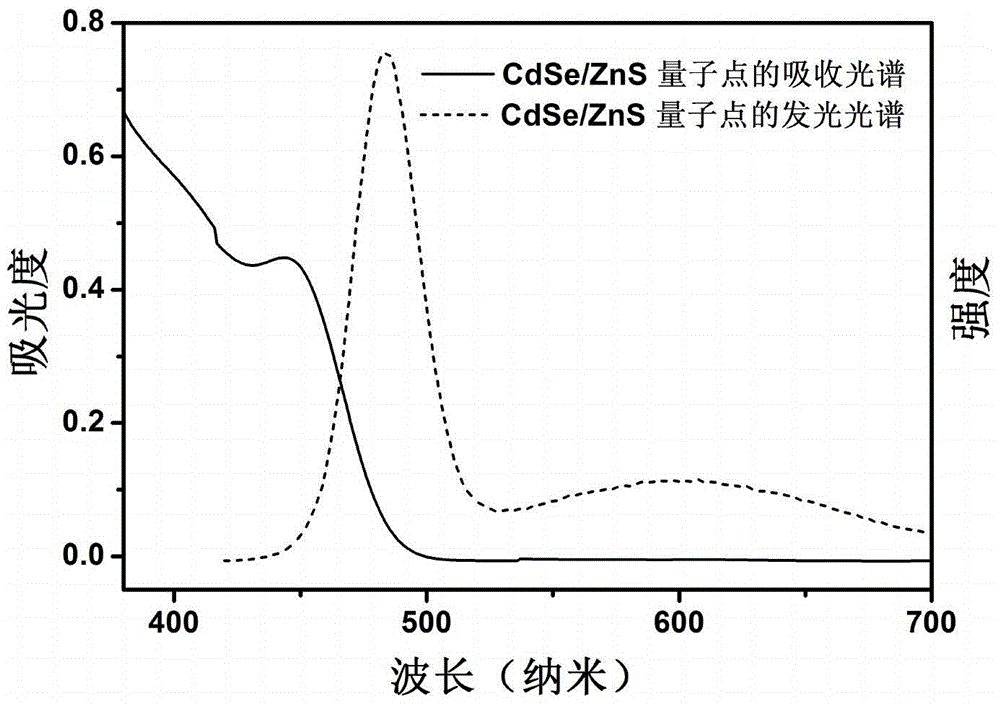

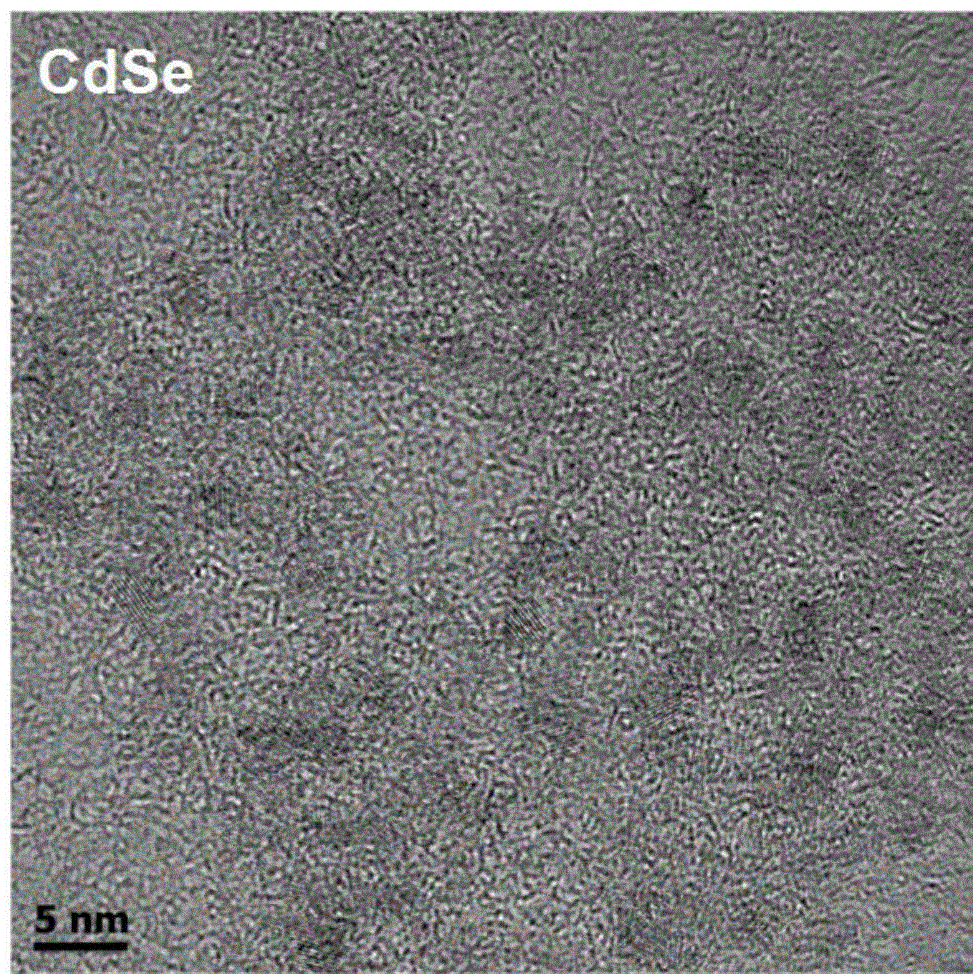

[0092] The preparation of quantum dots can be obtained by referring to the following literature [J.Phys.Chem.B,2003,107,8-13; Mater.Lett.2006,60,3782-3785; Ind.Eng.Chem.Res.2007,46 , 2013-2019; Chin. J. Inorg. Chem. 2008, 1186-1190.]. The present invention is exemplified as follows: take the preparation of CdSe / ZnS quantum dots as an example [Chin.J.Inorg.Chem.2008, 1186-1190]. The first step is to synthesize CdSe quantum dots. The experimental steps include: ① Preparation of Na 2 SeSO 3 : Weigh 40.0mg selenium powder (0.5mmoL) and add to 100mLNa 2 SO 3 (189mg) in aqueous solution, degassed for 30min. Heat to reflux until the selenium powder is completely dissolved to obtain clear and transparent Na 2 SeSO 3 Solution, pass argon gas for 30min, and store in the dark; ②Synthesize CdSe quantum dots. Add 46 mg of CdCl to a 500 mL single-necked round bottom flask 2 ·5 / 2H 2 O (0.2mmoL), 190mL deionized water, 26μL mercaptopropionic acid (0.3mmoL), adjust the pH value to 11....

Embodiment 1

[0096] A method for stably dispersing quantum dots synthesized in an aqueous phase in an organic solvent, comprising the following steps:

[0097] Take 50 mL of the prepared CdSe / ZnS quantum dot stock solution, evaporate and concentrate; put the concentrated CdSe / ZnS solution in a 50 mL centrifuge tube, add isopropanol for precipitation. Place the centrifuge tube in a centrifuge for centrifugation, the centrifugation speed is 5000r / min, and the centrifugation time is 10min. The precipitate is washed 2-3 times with chromatographically pure methanol. The purpose of washing with methanol is to purify the synthesized quantum dot solution and remove the solution containing the S 2- ,Zn 2+ and other impurity ions.

[0098] The purified 6.7×10 -7 molCdSe / ZnS quantum dots were placed in a 50mL centrifuge tube, 10mL of chromatographically pure methanol solution was added, and it was placed in an ultrasonic cleaner for 2 hours of sonication. At this time, CdSe / ZnS quantum dots can b...

Embodiment 2

[0100] A kind of synthetic method of oil phase quantum dot, comprises the following steps:

[0101] (1) Synthetic CdSe quantum dots in the oil phase: Weigh 0.06g CdO, 0.28g n-octadecyl phosphate (ODPA) and 3.0g tri-n-octylphosphine oxide (TOPO) mixture in a 25mL round bottom flask, argon protection Heat to 300°C under low temperature, until the CdO is completely dissolved, the solution becomes clear, inject 1.5g of tri-n-octylphosphine (TOP), raise the temperature to 350°C, quickly inject the precursor of (0.058gSe+0.36gTOP), stop heating after 5s .

[0102] (2) Oil-phase synthesis of CdSe / CdS core-shell quantum dots: Take 0.29g ODPA, 0.08g n-hexyl phosphoric acid (HPA), 0.06g CdO and 3.0g TOPO in a 25mL round bottom flask, heat to 300°C under the protection of argon, When CdO is completely dissolved, add 1.5gTOP, heat up to 350°C, quickly add CdSe (0.8μmol) and S source (0.12g sulfur powder dissolved in 1.5gTOP), stop heating after reacting for 8min, and obtain an orange col...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com