Glass film containing rare-earth-ion-doped K2LaBr5 microcrystalline and preparation method thereof

A rare earth ion and glass thin film technology, which is applied in the field of rare earth ion doped K2LaBr5 microcrystalline glass thin film and its sol-gel preparation, can solve problems such as device development limitations, overcome incomplete uniformity, prevent decomposition and volatilization , the effect of high transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

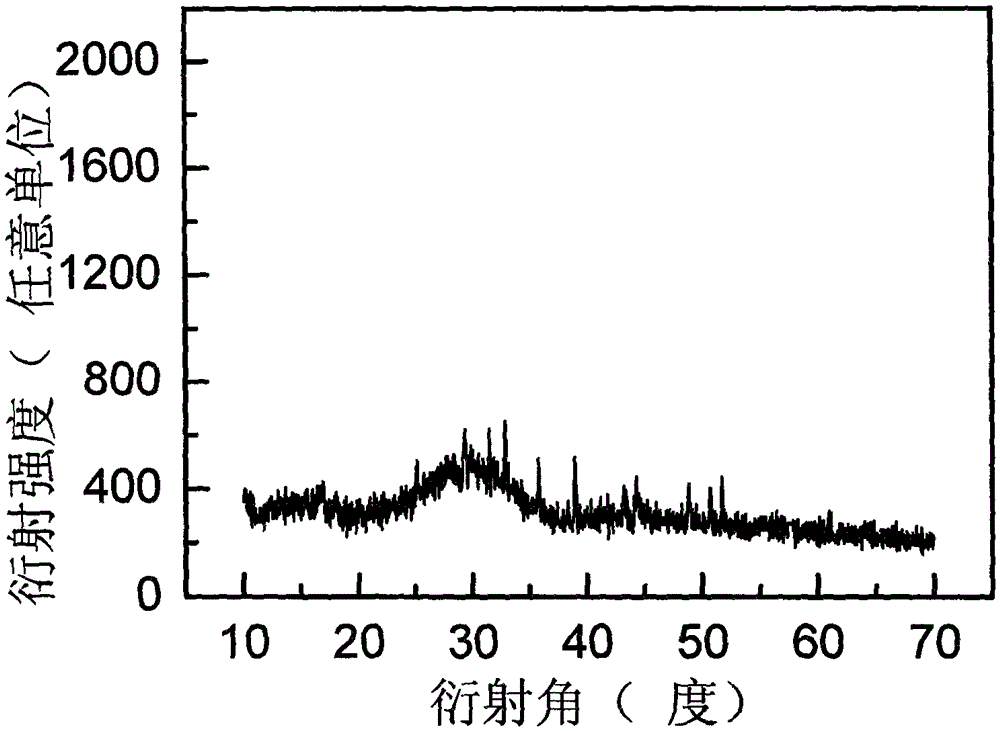

Embodiment 1

[0041] Doped with rare earth ions K 2 LaBr 5 The preparation method of the glass thin film of crystallite comprises following specific steps:

[0042] (1), prepare the raw materials in molar ratio: trimethyl phosphate: aluminum sec-butoxide: gallium ethoxide: potassium bromide: lanthanum bromide: cerium bromide = 148: 10: 20: 20: 10: 1, weigh A total amount of 30 grams of analytically pure raw materials for preparation, stand-by;

[0043] (2), the hydrolysis of trimethyl phosphate: dissolve the trimethyl phosphate weighed in step (1) in dehydrated alcohol, the mol ratio of dehydrated alcohol and trimethyl phosphate is 2: 1, add acetylacetone rapidly , the volume ratio of trimethyl phosphate to acetylacetone is 1:0.8, and strong magnetic stirring is carried out, and distilled water is gradually added dropwise. The molar ratio of distilled water to trimethyl phosphate is 0.6:1, and the hydrolysis reaction is carried out at room temperature for 1 hour to prepare into solution ...

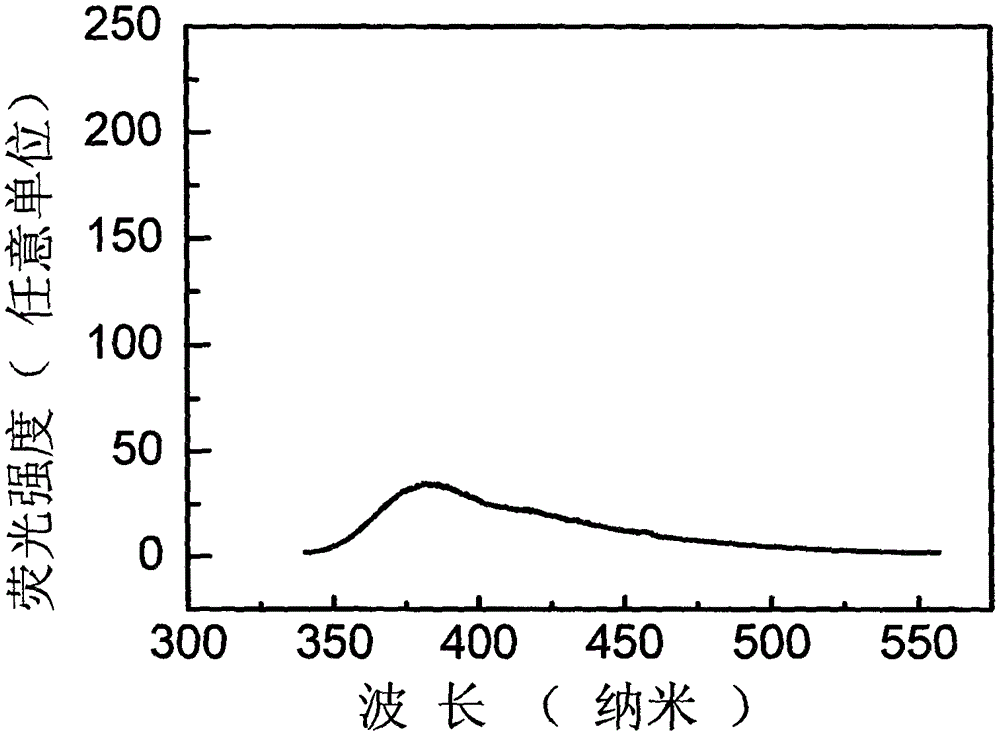

Embodiment 2

[0054] It is basically the same as Example 1, except that in the step (1), the raw materials are prepared according to the following molar ratio: trimethyl phosphate: aluminum sec-butoxide: gallium ethylate: potassium bromide: lanthanum bromide: europium bromide=130 : 20: 10: 30: 15: 5, weigh each raw material respectively; in step (7), the pulling speed of the glass substrate in the gel solution is controlled at 1 mm / s, and the pulling is repeated 5 times, each time Pull interval time is 15 minutes; In step (9), be warming up to 100 ℃ with the rate of 50 ℃ per hour, then heat up furnace to 340 ℃ with the rate of 50 ℃ per hour; In step (9), gradually heat up furnace to 560°C, and reacted at this temperature for 2 hours, and finally obtained Eu-containing 3+ Ion-doped K 2 LaBr 5 Microcrystalline 65P 2 o 5 -10Al 2 o 3 -5Ga 2 o 3 -15K 2 LaBr 5 -5EuBr 3 System glass film.

[0055] For prepared Eu-containing 3+ Ion-doped K 2 LaBr 5 Microcrystalline glass film for per...

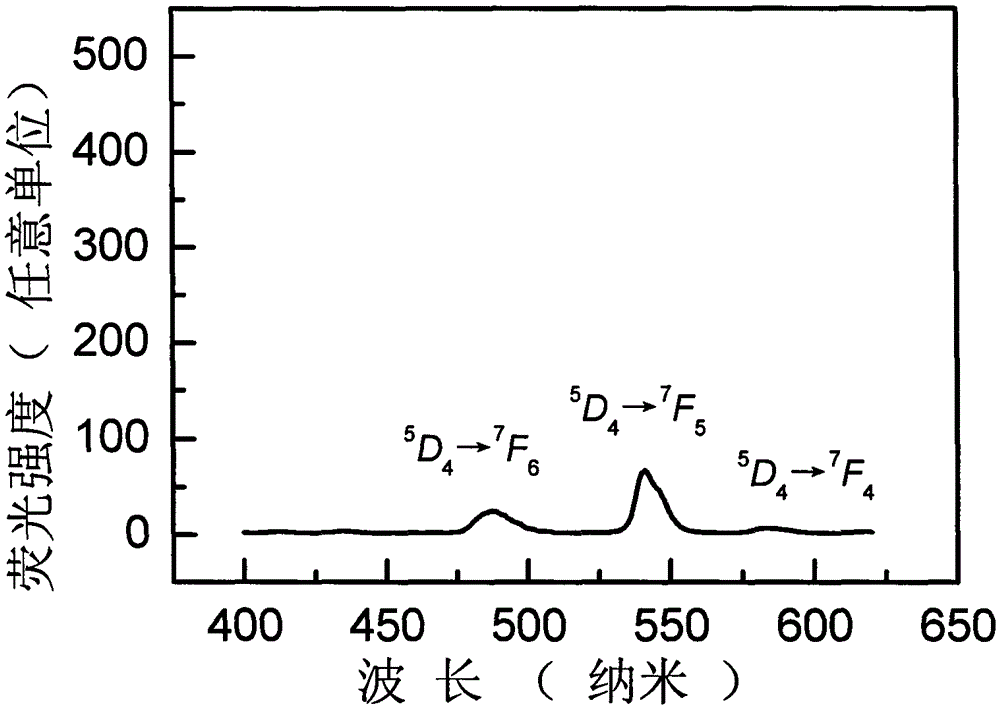

Embodiment 3

[0057]It is basically the same as Example 1, except that in the step (1), the raw materials are prepared according to the following molar ratios: trimethyl phosphate: aluminum sec-butoxide: gallium ethylate: potassium bromide: lanthanum bromide: terbium bromide=144 : 14: 14: 24: 12: 2, weigh each raw material respectively; in step (7), the pulling speed of the glass substrate in the gel solution is controlled at 0.6 mm / s, and the pulling is repeated 3 times, each time Pull interval time is 15 minutes; In step (9), be warming up to 100 ℃ with the rate of 40 ℃ per hour, then heat up furnace to 340 ℃ with the rate of 40 ℃ per hour; In step (10), gradually heat up furnace to 550°C, and reacted at this temperature for 3 hours, and finally obtained Tb-containing 3+ Ion-doped K 2 LaBr 5 Microcrystalline 72P 2 o 5 -7Al 2 o 3 -7Ga 2 o 3 -12K 2 LaBr 5 -2EuBr 3 System glass film.

[0058] For prepared Tb-containing 3+ Ion-doped K 2 LaBr 5 Microcrystalline glass film for pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com