Method for preparing ethylene, aromatic hydrocarbon and hydrogen by directly converting methane under anaerobic condition with photovoltaic polysilicon cutting waste material as catalyst

A catalytic conversion and catalyst technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of high production cost and cumbersome process, and achieve easy separation, wide sources and low price Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

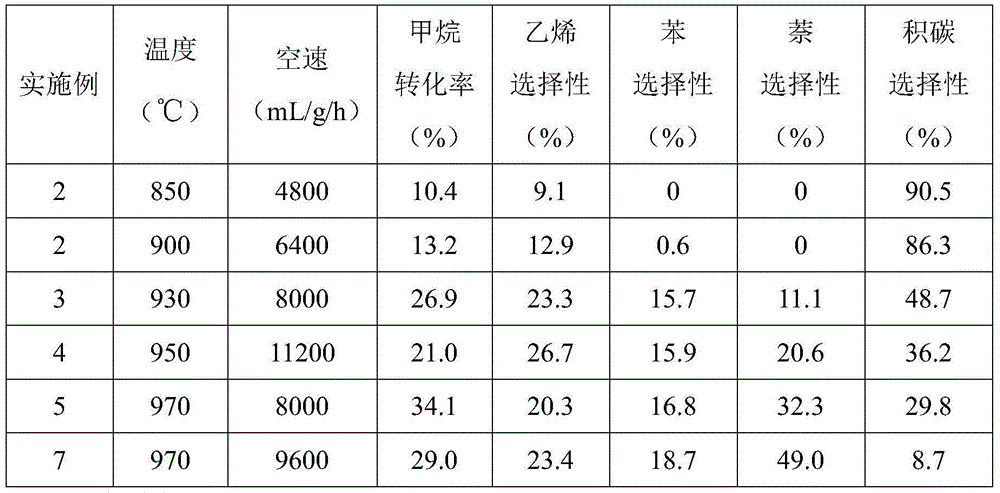

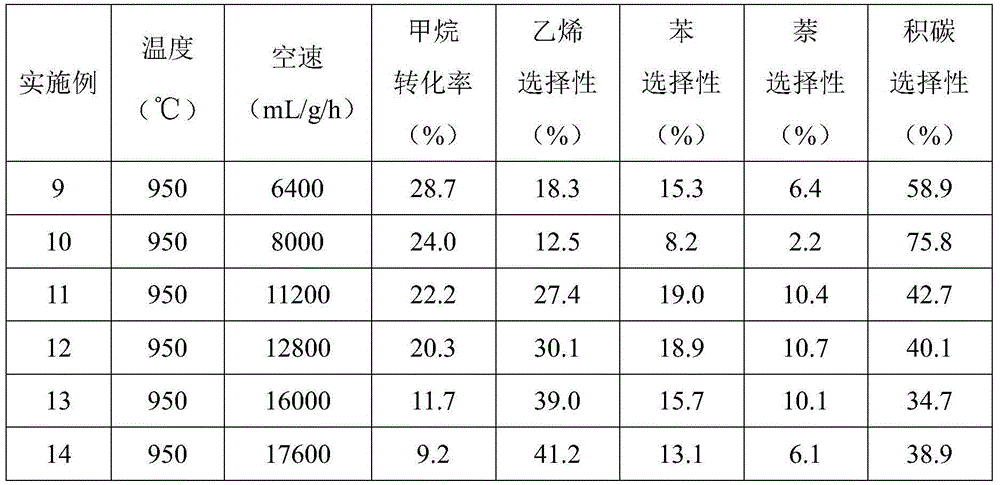

Examples

preparation example Construction

[0029] 1. Catalyst preparation

[0030] The prepared photovoltaic polysilicon cutting waste catalysts all need to go through the process of catalyst pre-selection and selection.

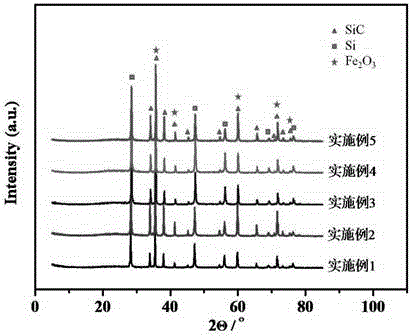

[0031] The photovoltaic polysilicon cutting waste raw material used in the catalyst preparation process is a brown powdery substance, and its main components are silicon carbide (SiC), iron (Fe), polyethylene glycol (PEG) and silicon powder (Si). The proportions are SiC (47-52%), Fe (4-6%), PEG (1-2%) and Si (40-48%).

Embodiment 1

[0033] Accurately weigh 10g of photovoltaic polysilicon cutting waste raw material, add 200mL of ethanol and 400mL of acetone and (1:2) mixed solvent, stir magnetically for 12h, then use filtration to remove residual solvent, and dry the obtained sample at 120°C for 24h in an air atmosphere. Obtain the desired photovoltaic polysilicon cutting waste catalyst A.

Embodiment 2

[0035] Weigh 5g of the photovoltaic polysilicon cutting waste A obtained according to Example 1, add 300mL of nitric acid solution with a mass concentration of 10%, magnetically stir for 12h, and then remove residual solvent by filtration and separation, and dry the obtained sample at 120°C for 24h in an air atmosphere , to obtain the desired photovoltaic polysilicon cutting waste catalyst B.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com