Fluorocarbon self-cleaning coating and preparation method thereof

A self-cleaning, fluorocarbon technology, applied in the direction of coating, etc., can solve the problems of affecting the appearance, reducing the product storage period, powdering and falling off of the coating, etc., achieving long-term stable self-cleaning, simplifying the coating process, and low water contact angle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

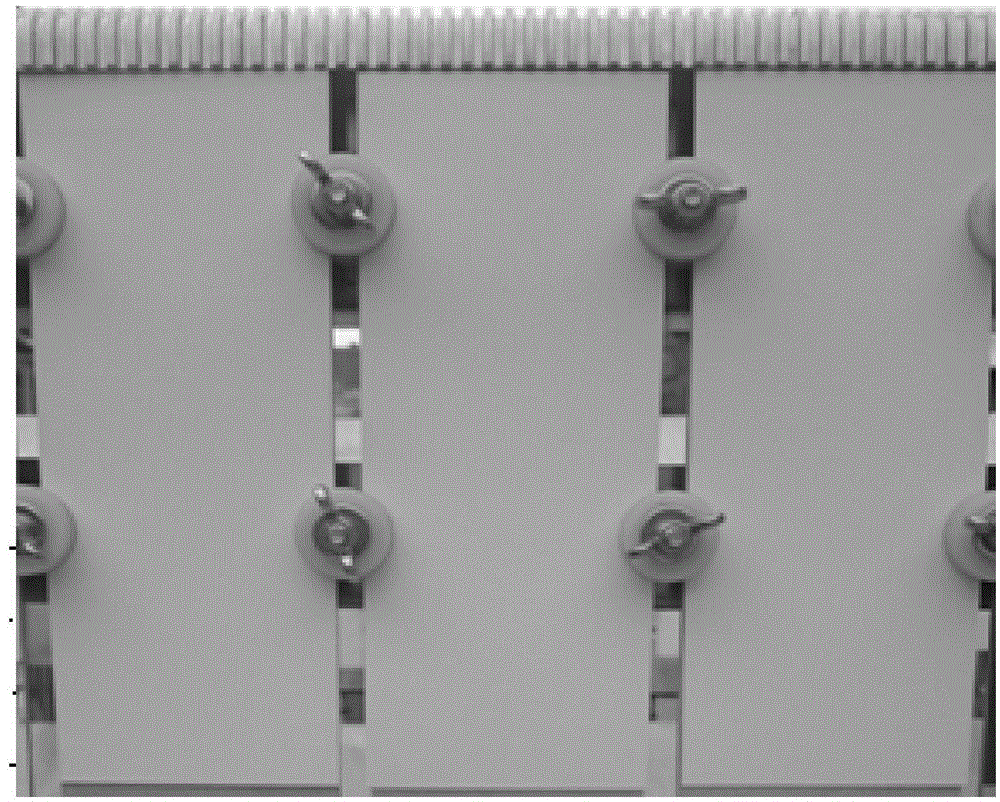

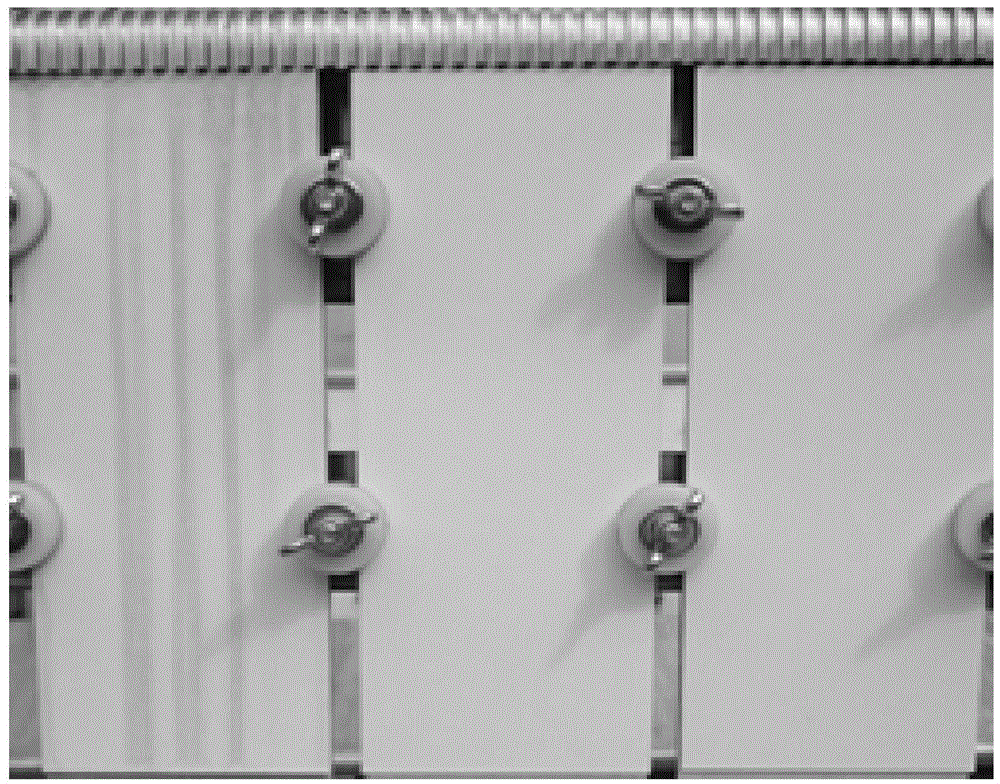

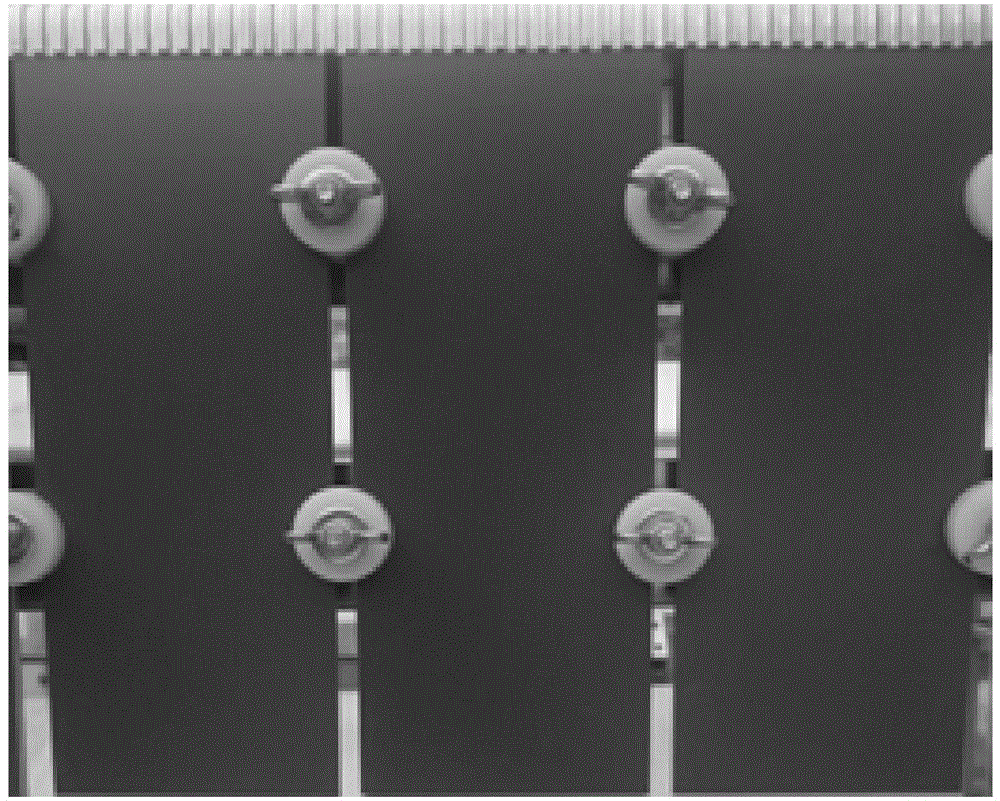

Image

Examples

Embodiment 1

[0047]Add 25g n-butanol and 72.5g methyl alcohol in a four-necked flask equipped with stirring paddle, thermometer, condenser tube and nitrogen (the whole reaction process is carried out under nitrogen protection) inlet pipe and add in the reaction vessel and stir at a constant speed, and the water bath is heated to 40- 50°C, put 50g of hydroxysiloxane and 100g of methyltrimethoxysilane into the reaction vessel at 40°C to 50°C, stir for 30 to 40 minutes, then drop 4.5g of vinyltrimethoxysilane and 1g of dilaurel After the addition of the dibutyltin acid mixture was completed, the temperature was raised to 80° C. with stirring, and the reaction was carried out at a constant temperature for 6 hours. The temperature was lowered to room temperature and the material was discharged to obtain a methoxy-terminated polysiloxane with a degree of polymerization of 4.

[0048] Add 32g fluorocarbon resin, 6g acrylic resin, 30g rutile titanium dioxide, 1g polydimethylsiloxane, 2g fatty acid ...

Embodiment 2

[0054] Add 75% solvent of 100g butyl acetate and 30g methanol total amount in a four-necked flask equipped with a stirring paddle, a thermometer, a condenser tube and a nitrogen inlet pipe and add it to the reaction vessel to stir at a constant speed, and the water bath is heated to 40-50°C. Put 50g of hydroxysiloxane and 119g of methyltriethoxysilane into the reaction vessel at 40°C to 50°C, stir for 30 to 40 minutes, then add 4.1g of vinyltrimethoxysilane and 1.3g of dilauric acid dropwise The mixture of dibutyltin, after the dropwise addition is completed, stir and heat up to 80°C, react at a constant temperature for 6h, cool down to room temperature and discharge, and prepare ethoxy-terminated polysiloxane with a degree of polymerization of 4. The entire reaction process is carried out under nitrogen protection. .

[0055] Add 32g of fluorocarbon resin, 10g of acrylic resin, 15g of rutile titanium dioxide, 17g of iron oxide red, 1g of polydimethylsiloxane, 2g of fatty acid...

Embodiment 3

[0058] Add 75% solvent of 80g butyl acetate and 30g xylene to a four-neck flask equipped with stirring paddle, thermometer, condenser tube and nitrogen gas inlet tube, add to the reaction vessel and stir at a constant speed, and the water bath is heated to 40-50°C , put 38g of hydroxysiloxane and 70g of methyltriethoxysilane into the reaction vessel at 40℃~50℃, stir for 1h, then add dropwise 32g of methyltributoxysilane and 0.7g of dibutyltin diacetate After the dropwise addition, the mixture was stirred and heated to 80°C, reacted at a constant temperature for 5 hours, cooled to room temperature and discharged to prepare an ethoxybutoxy-terminated polysiloxane with a degree of polymerization of 12. The entire reaction process was carried out under nitrogen protection. .

[0059] Add 34g fluorocarbon resin, 9g acrylic resin, 27g rutile titanium dioxide, 1g polydimethylsiloxane, 2g fatty acid polyethylene glycol ester, 2g polytetrafluoroethylene, 25g isophorone and the remainin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com