A preparation method of adsorption-enhanced visible-light catalysis low-concentration vocs titanium dioxide composite material

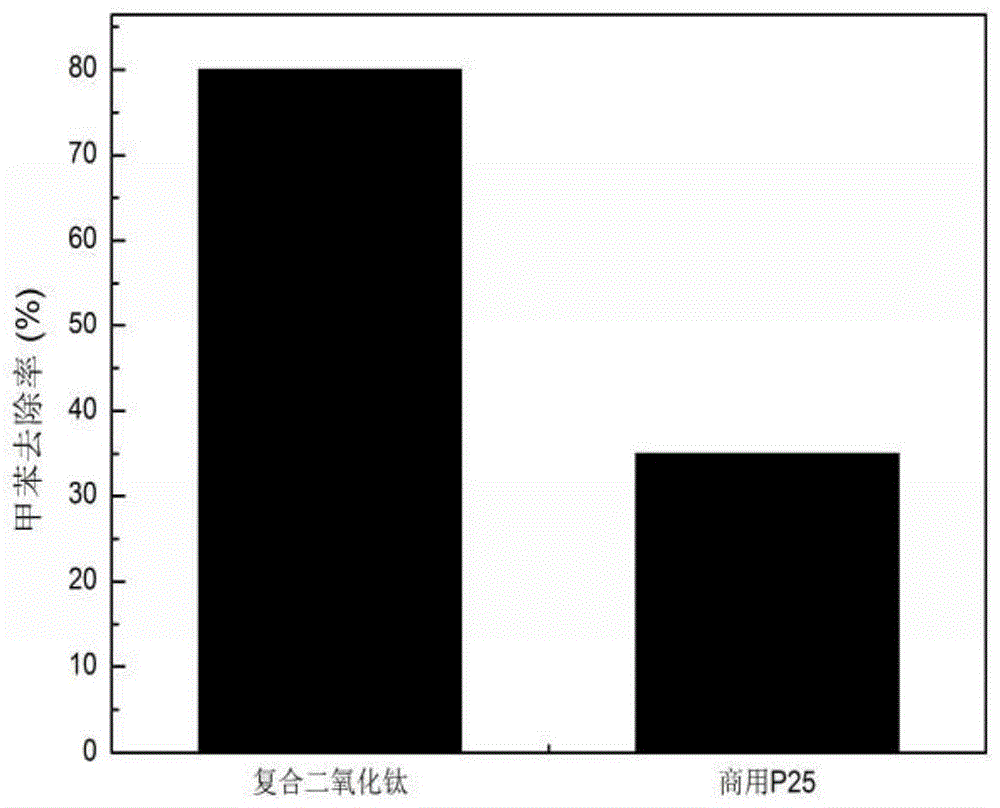

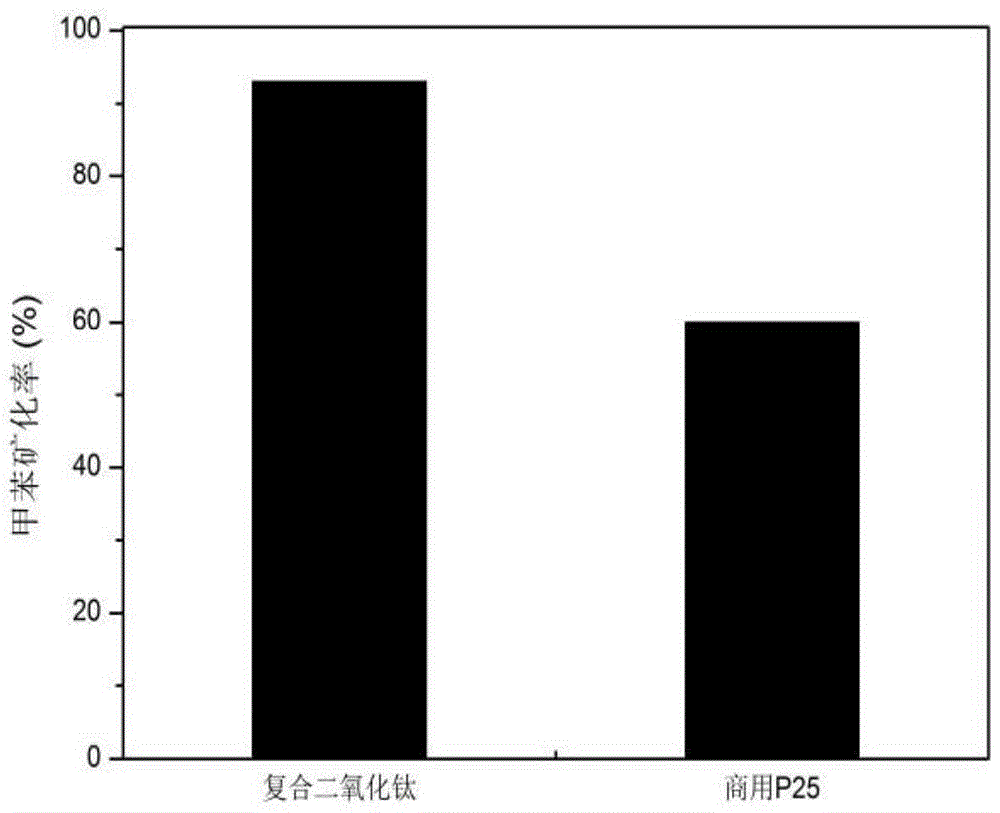

A technology of titanium dioxide and composite materials, which is applied in the field of photocatalysis, can solve the problems of low utilization rate of light energy, achieve the effects of improving adsorption and photocatalytic degradation performance, large specific surface area, and reducing indoor health risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

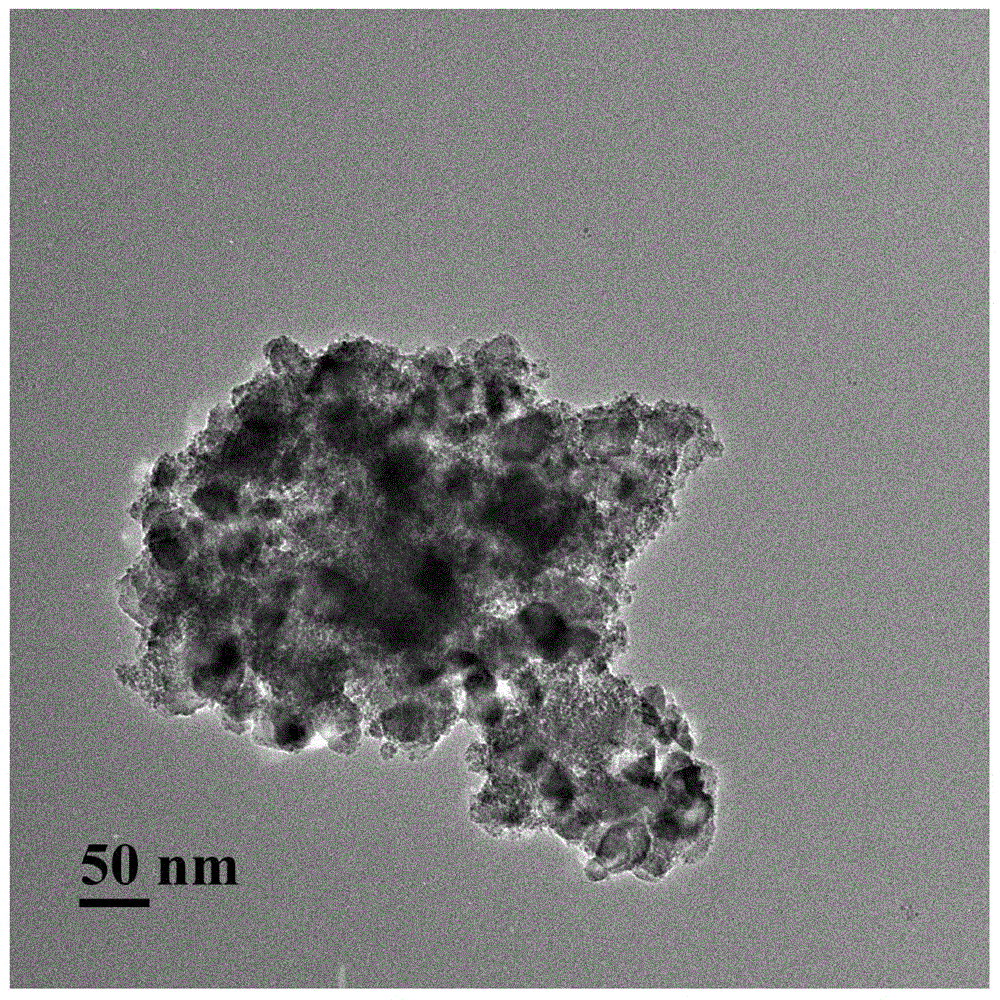

Embodiment 1

[0031] Mix hydrochloric acid with titanium tetrachloride, wherein the molar ratio of hydrogen chloride to titanium tetrachloride is 1:28. Add P25 to the obtained solution to form a suspension with a mass ratio of 1:15, and stir in a water bath at 80°C for 1 hour. The obtained suspension was centrifuged and washed 5 times with water, and the obtained solid was naturally air-dried. The obtained solid powder was heated at 500° C. for 30 min to obtain the seed crystal P25 solid. Under vigorous stirring conditions, the prepared powder was added into absolute ethanol to form a suspension with a concentration of 8 g / L, and the suspension was stirred for 0.1 h. Add 4-ethylaniline to the above suspension to form a mixed solution with a 4-ethylaniline concentration of 2 mmol / L. Add butyl titanate to the absolute ethanol solution to form a butyl titanate ethanol solution with a concentration of 300 mmol / L. Add the butyl titanate ethanol solution dropwise to the above mixed solution, t...

Embodiment 2

[0034] Mix hydrochloric acid with titanium tetrachloride, wherein the molar ratio of hydrogen chloride to titanium tetrachloride is 1:40. Add P25 to the obtained solution to form a suspension with a mass ratio of 1:15, and stir in a water bath at 80°C for 2 hours. The obtained suspension was centrifuged and washed 12 times with water, and the obtained solid was naturally air-dried. The obtained solid powder was heated at 300° C. for 350 min to obtain a seed crystal P25 solid. Under the condition of vigorous stirring, the prepared powder was added into absolute ethanol to form a suspension with a concentration of 1 g / L, and the suspension was stirred for 0.1 h. Add 4-ethylaniline to the above suspension to form a mixed solution with a 4-ethylaniline concentration of 2 mmol / L. Add butyl titanate to the absolute ethanol solution to form a butyl titanate ethanol solution with a concentration of 300 mmol / L. Add the butyl titanate ethanol solution dropwise to the above mixed solu...

Embodiment 3

[0037]Mix hydrochloric acid with titanium tetrachloride, wherein the molar ratio of hydrogen chloride to titanium tetrachloride is 1:10. Add P25 to the obtained solution to form a suspension with a mass ratio of 1:60, and stir in a water bath at 60°C for 5 hours. The obtained suspension was centrifuged and washed 5 times with water, and the obtained solid was naturally air-dried. The obtained solid powder was heated at 500° C. for 30 min to obtain the seed crystal P25 solid. Under the condition of vigorous stirring, the obtained powder was added into absolute ethanol to form a suspension with a concentration of 30 g / L, and the suspension was stirred for 1.5 h. Add 4-ethylaniline to the above suspension to form a mixed solution with a 4-ethylaniline concentration of 0.2 mmol / L. Add butyl titanate to the absolute ethanol solution to form a butyl titanate ethanol solution with a concentration of 600 mmol / L. Add the butyl titanate ethanol solution dropwise to the above mixed so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com