Defoaming agent for boiler water treatment and preparation method thereof

A defoamer and boiler water technology, applied in the field of water treatment, can solve the problems of lack of defoamers, non-existence, etc., and achieve excellent defoaming and antifoaming effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

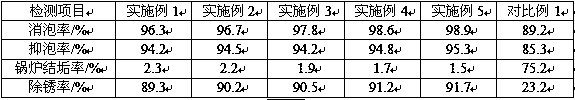

Examples

Embodiment 1

[0018] A defoamer for boiler water treatment, containing the following components in parts by mass: 3 parts of polypropylene glycol stearate, 75 parts of ethylene oxide, 2 parts of epichlorohydrin, 0.5 part of isopropanol, stearic acid 1.5 parts, 6 parts of triethanolamine oleic acid soap, 0.2 parts of water glass, 0.2 parts of didecyldimethylammonium chloride, 0.6 parts of isotridecyl polyoxyethylene ether, 0.05 parts of ammonium bifluoride, sodium alginate 0.4 parts, 0.2 parts of manganese dihydrogen phosphate, and 0.1 parts of copper carbonate.

[0019] A preparation method of a defoamer for boiler water treatment, the steps of the preparation method are as follows:

[0020] Step 1: Add polypropylene glycol stearate, ethylene oxide, epichlorohydrin, isopropanol, stearic acid, triethanolamine oleic acid soap, and water glass into the reaction kettle, and mix at a temperature of 50°C Uniform;

[0021] The second step: Add didecyldimethylammonium chloride, isotridecyl polyox...

Embodiment 2

[0024] A defoamer for boiler water treatment, containing the following components in parts by mass: 9 parts of polypropylene glycol stearate, 95 parts of ethylene oxide, 7 parts of epichlorohydrin, 2.1 parts of isopropanol, stearic acid 4.5 parts, 13 parts of triethanolamine oleic acid soap, 0.6 parts of water glass, 0.5 parts of didecyldimethylammonium chloride, 1.5 parts of isotridecyl polyoxyethylene ether, 0.15 parts of ammonium bifluoride, sodium alginate 1 part, 0.6 part of manganese dihydrogen phosphate, and 0.5 part of copper carbonate.

[0025] A preparation method of a defoamer for boiler water treatment, the steps of the preparation method are as follows:

[0026] Step 1: Add polypropylene glycol stearate, ethylene oxide, epichlorohydrin, isopropanol, stearic acid, triethanolamine oleic acid soap, and water glass into the reaction kettle, and mix at a temperature of 70°C Uniform;

[0027] The second step: Add didecyldimethylammonium chloride, isotridecyl polyoxyet...

Embodiment 3

[0030] A defoamer for boiler water treatment, containing the following components in parts by mass: 8 parts of polypropylene glycol stearate, 90 parts of ethylene oxide, 6 parts of epichlorohydrin, 1.8 parts of isopropanol, stearic acid 4 parts, 12 parts of triethanolamine oleic acid soap, 0.5 parts of water glass, 0.45 parts of didecyldimethylammonium chloride, 1.3 parts of isotridecyl polyoxyethylene ether, 0.12 parts of ammonium bifluoride, sodium alginate 0.9 parts, 0.5 parts of manganese dihydrogen phosphate, and 0.4 parts of copper carbonate.

[0031] A preparation method of a defoamer for boiler water treatment, the steps of the preparation method are as follows:

[0032] Step 1: Add polypropylene glycol stearate, ethylene oxide, epichlorohydrin, isopropanol, stearic acid, triethanolamine oleic acid soap, and water glass into the reaction kettle, and mix at a temperature of 60°C Uniform;

[0033] The second step: Add didecyldimethylammonium chloride, isotridecyl polyo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com